Hand-packed ice cream offers artisanal quality with a personalized touch, ensuring careful portion control and minimal air incorporation for a denser texture. Machine-filled packaging excels in efficiency, producing consistent sizes and sealed containers suitable for large-scale distribution. Choosing between hand-packed and machine-filled methods depends on priorities like texture, production speed, and quality assurance.

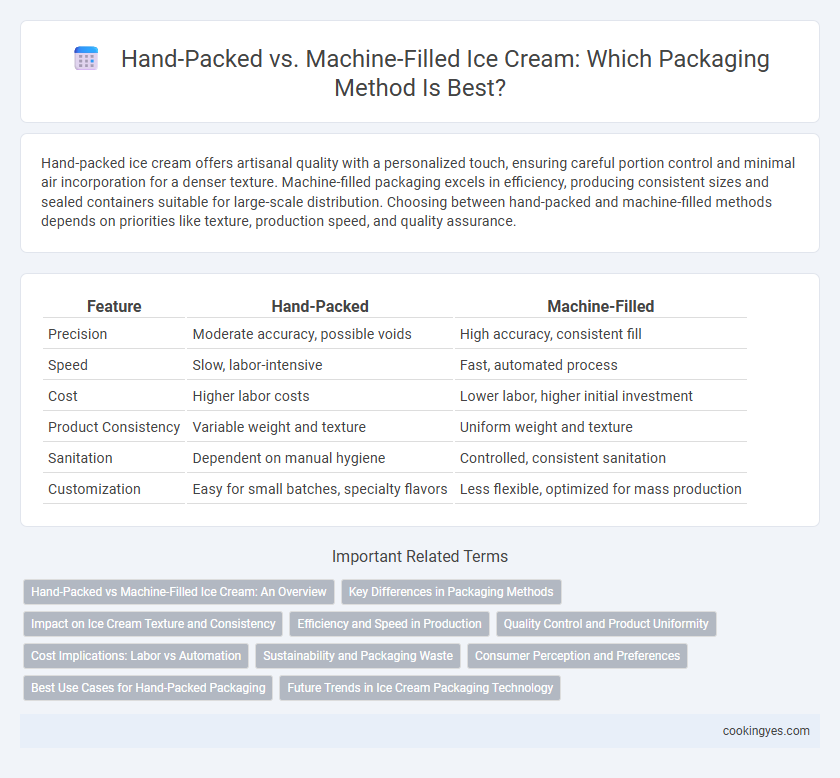

Table of Comparison

| Feature | Hand-Packed | Machine-Filled |

|---|---|---|

| Precision | Moderate accuracy, possible voids | High accuracy, consistent fill |

| Speed | Slow, labor-intensive | Fast, automated process |

| Cost | Higher labor costs | Lower labor, higher initial investment |

| Product Consistency | Variable weight and texture | Uniform weight and texture |

| Sanitation | Dependent on manual hygiene | Controlled, consistent sanitation |

| Customization | Easy for small batches, specialty flavors | Less flexible, optimized for mass production |

Hand-Packed vs Machine-Filled Ice Cream: An Overview

Hand-packed ice cream offers artisanal quality with carefully portioned servings, preserving texture and flavor through manual attention. Machine-filled ice cream emphasizes efficiency and uniformity, utilizing automated processes for consistent packaging and faster production rates. Choosing between hand-packed and machine-filled options depends on prioritizing craftsmanship versus scalability in ice cream production.

Key Differences in Packaging Methods

Hand-packed ice cream packaging features artisanal precision with each container filled individually, ensuring consistent texture and minimal air incorporation. Machine-filled packaging offers high-speed, uniform portioning using automated technology, optimizing production efficiency and reducing human error. Key differences lie in production scale, consistency, and packaging quality, affecting consumer perception and shelf life.

Impact on Ice Cream Texture and Consistency

Hand-packed ice cream offers a denser, creamier texture by minimizing air incorporation, resulting in a richer mouthfeel favored by artisanal brands. Machine-filled packaging often introduces more air, known as overrun, which can create a lighter, fluffier consistency but may compromise the ice cream's smoothness and overall richness. The packaging method directly influences ice crystal size and texture uniformity, with hand-packing promoting better control over product consistency and sensory quality.

Efficiency and Speed in Production

Hand-packed ice cream offers artisanal quality but is significantly slower and less efficient compared to machine-filled packaging. Automated machines can fill hundreds of containers per minute, ensuring consistent portion sizes and reducing labor costs. This increased speed and efficiency make machine-filling the preferred choice for large-scale ice cream production.

Quality Control and Product Uniformity

Hand-packed ice cream packaging allows for meticulous quality control by enabling inspectors to detect inconsistencies in texture and ingredient distribution. Machine-filled packaging offers high product uniformity through automated dosing systems that ensure consistent portion sizes and weight accuracy. Both methods impact the overall consumer experience, with hand-packing favoring artisanal quality and machine-filling optimizing production efficiency.

Cost Implications: Labor vs Automation

Hand-packed ice cream packaging incurs higher labor costs due to manual handling and quality control, increasing overall production expenses. Machine-filled packaging significantly reduces labor requirements, offering cost savings through faster throughput and consistent portioning. Automation investments involve upfront capital but yield long-term reductions in packaging costs and improved scalability.

Sustainability and Packaging Waste

Hand-packed ice cream typically uses reusable or biodegradable containers, significantly reducing packaging waste compared to machine-filled products that often rely on single-use plastic packaging. Sustainable packaging in hand-packed ice cream supports lower carbon footprints by minimizing production energy and material waste. Consumers favor brands that emphasize eco-friendly packaging solutions, reflecting increasing demand for sustainability in the ice cream industry.

Consumer Perception and Preferences

Hand-packed ice cream is often perceived by consumers as artisanal and higher quality due to its traditional preparation and attention to detail, appealing to those who value authenticity and craftsmanship. Machine-filled packaging ensures consistent portion sizes and is preferred for its uniformity and convenience, attracting customers seeking efficiency and reliability. Consumer preference largely depends on the desired experience, with hand-packed products favored for uniqueness and machine-filled options chosen for standardization.

Best Use Cases for Hand-Packed Packaging

Hand-packed ice cream packaging is ideal for artisanal brands emphasizing small-batch quality and unique flavor combinations, offering greater control over presentation and texture consistency. This method suits premium product lines where customization, limited editions, or intricate mix-ins require precise handling to maintain product integrity. Restaurants and gourmet shops benefit from hand-packed packaging as it enhances visual appeal and supports branding focused on craftsmanship and exclusivity.

Future Trends in Ice Cream Packaging Technology

Future trends in ice cream packaging technology emphasize sustainability and customization, with innovations in biodegradable materials and smart packaging sensors that monitor freshness. Advances in automated hand-packed style machines aim to replicate artisanal quality while increasing efficiency and reducing labor costs. Integration of QR codes and NFC chips enhances consumer engagement by providing traceability and personalized product information.

Hand-Packed vs Machine-Filled for Packaging Infographic

cookingyes.com

cookingyes.com