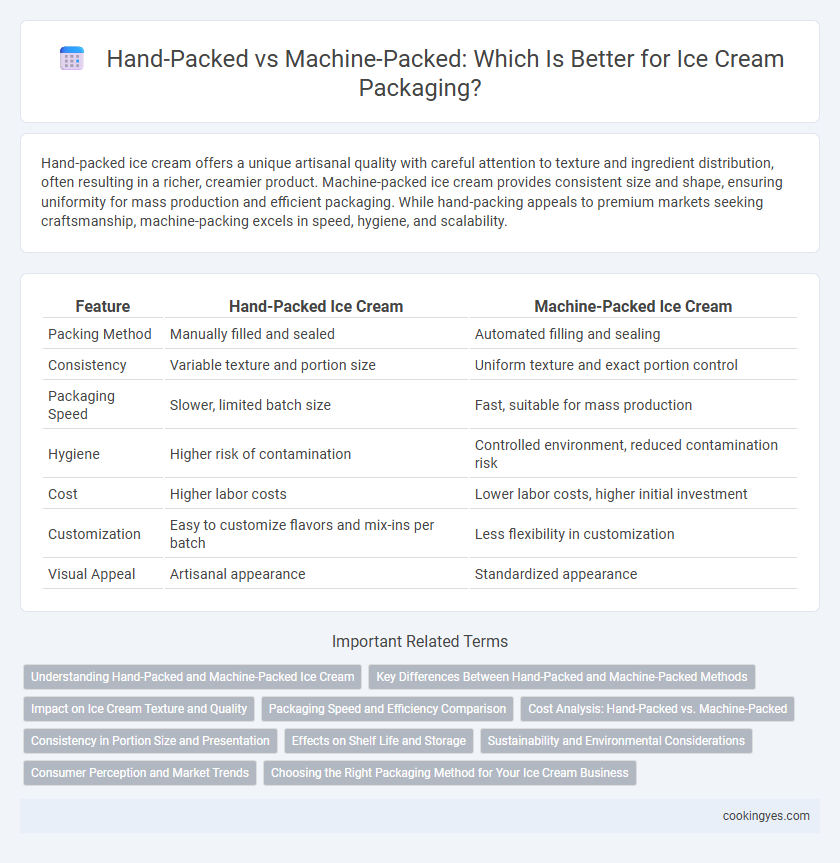

Hand-packed ice cream offers a unique artisanal quality with careful attention to texture and ingredient distribution, often resulting in a richer, creamier product. Machine-packed ice cream provides consistent size and shape, ensuring uniformity for mass production and efficient packaging. While hand-packing appeals to premium markets seeking craftsmanship, machine-packing excels in speed, hygiene, and scalability.

Table of Comparison

| Feature | Hand-Packed Ice Cream | Machine-Packed Ice Cream |

|---|---|---|

| Packing Method | Manually filled and sealed | Automated filling and sealing |

| Consistency | Variable texture and portion size | Uniform texture and exact portion control |

| Packaging Speed | Slower, limited batch size | Fast, suitable for mass production |

| Hygiene | Higher risk of contamination | Controlled environment, reduced contamination risk |

| Cost | Higher labor costs | Lower labor costs, higher initial investment |

| Customization | Easy to customize flavors and mix-ins per batch | Less flexibility in customization |

| Visual Appeal | Artisanal appearance | Standardized appearance |

Understanding Hand-Packed and Machine-Packed Ice Cream

Hand-packed ice cream involves artisans manually filling containers, ensuring a dense texture and customized portion control, often resulting in higher quality and richer flavor profiles. Machine-packed ice cream uses automated equipment to fill and seal containers rapidly, enabling mass production with consistent weight and sanitation standards. Both methods significantly affect the texture, taste experience, and consumer perception of premium versus commercial ice cream products.

Key Differences Between Hand-Packed and Machine-Packed Methods

Hand-packed ice cream offers artisanal quality with careful portion control, ensuring texture and flavor consistency through manual handling, while machine-packed ice cream provides higher efficiency and uniformity suited for large-scale production. Hand-packing allows for customization and slower freezing rates that preserve creaminess, whereas machine-packing emphasizes speed, automation, and airtight sealing to extend shelf life. The choice between hand-packed and machine-packed packaging impacts product freshness, batch variability, and production costs significantly.

Impact on Ice Cream Texture and Quality

Hand-packed ice cream maintains a richer, creamier texture due to minimal air incorporation and gentle handling, preserving flavor depth and smoothness. Machine-packed ice cream often contains higher overrun, introducing more air, which can lead to a lighter but less dense consistency and potential ice crystal formation during storage. The choice between hand-packed and machine-packed methods directly influences ice cream's mouthfeel, texture stability, and overall sensory quality.

Packaging Speed and Efficiency Comparison

Hand-packed ice cream allows for meticulous quality control but is significantly slower, impacting overall packaging speed and efficiency. Machine-packed ice cream drastically increases throughput by automating the filling and sealing process, ensuring consistent portion sizes and reducing labor costs. High-speed packaging machines enable ice cream manufacturers to meet large-scale demand while maintaining hygiene standards and minimizing product waste.

Cost Analysis: Hand-Packed vs. Machine-Packed

Hand-packed ice cream typically incurs higher labor costs due to manual labor intensity and slower production rates, increasing overall packaging expenses. Machine-packed ice cream benefits from automated processes that reduce labor costs and enhance consistency, leading to greater cost efficiency at scale. Despite higher upfront investment in machinery, machine-packed packaging delivers lower per-unit costs compared to hand-packed alternatives in commercial ice cream production.

Consistency in Portion Size and Presentation

Hand-packed ice cream often results in inconsistent portion sizes and variations in presentation due to manual scooping techniques, which can affect customer experience and portion control. Machine-packed ice cream ensures uniform portion sizes and a consistent, visually appealing presentation by using precise automated processes. This consistency improves inventory management and enhances brand perception through standardized packaging quality.

Effects on Shelf Life and Storage

Hand-packed ice cream typically exhibits shorter shelf life due to irregular sealing, which increases exposure to air and potential contamination. Machine-packed ice cream benefits from uniform sealing and airtight packaging, significantly reducing freezer burn and preserving texture and flavor longer. Consistent packaging in machine-packed ice cream optimizes cold storage efficiency, maintaining product integrity throughout extended distribution periods.

Sustainability and Environmental Considerations

Hand-packed ice cream often utilizes biodegradable or recyclable packaging materials, reducing plastic waste and lowering environmental impact compared to machine-packed varieties that typically require more energy-intensive production methods and non-recyclable containers. Machine-packed ice cream, while efficient for mass production, frequently employs plastic tubs and seals that contribute to landfill volume and microplastic pollution. Sustainable packaging innovations in hand-packed ice cream, such as compostable containers and minimal packaging designs, demonstrate a stronger commitment to ecological responsibility and waste reduction.

Consumer Perception and Market Trends

Hand-packed ice cream conveys a premium, artisanal image that appeals to consumers seeking authenticity and high-quality craftsmanship, often associated with small-batch production. Machine-packed ice cream guarantees consistency, speed, and scalability, meeting the demands of mass-market distribution but sometimes lacking the perceived uniqueness valued by niche markets. Current market trends show a growing consumer preference for hand-packed varieties in specialty shops, while machine-packed options dominate retail shelves due to cost efficiency and convenience.

Choosing the Right Packaging Method for Your Ice Cream Business

Hand-packed ice cream offers artisanal quality and customizable presentation, ideal for boutique brands emphasizing craftsmanship and flavor integrity. Machine-packed packaging ensures consistency, efficiency, and scalability, making it suitable for larger ice cream businesses aiming to reduce labor costs and maintain uniform product quality. Selecting the right packaging method depends on your business size, brand positioning, and production volume to optimize customer appeal and operational efficiency.

Hand-packed vs Machine-packed for ice cream packaging Infographic

cookingyes.com

cookingyes.com