Single-stage aging involves maturing the ice cream mix at a constant temperature for a set period, enhancing fat crystallization and protein hydration for a smoother texture. Multi-stage aging employs sequential temperature changes to optimize fat crystallization and protein functionality, resulting in improved creaminess and stability. Selecting the appropriate aging method influences the final ice cream quality and shelf life.

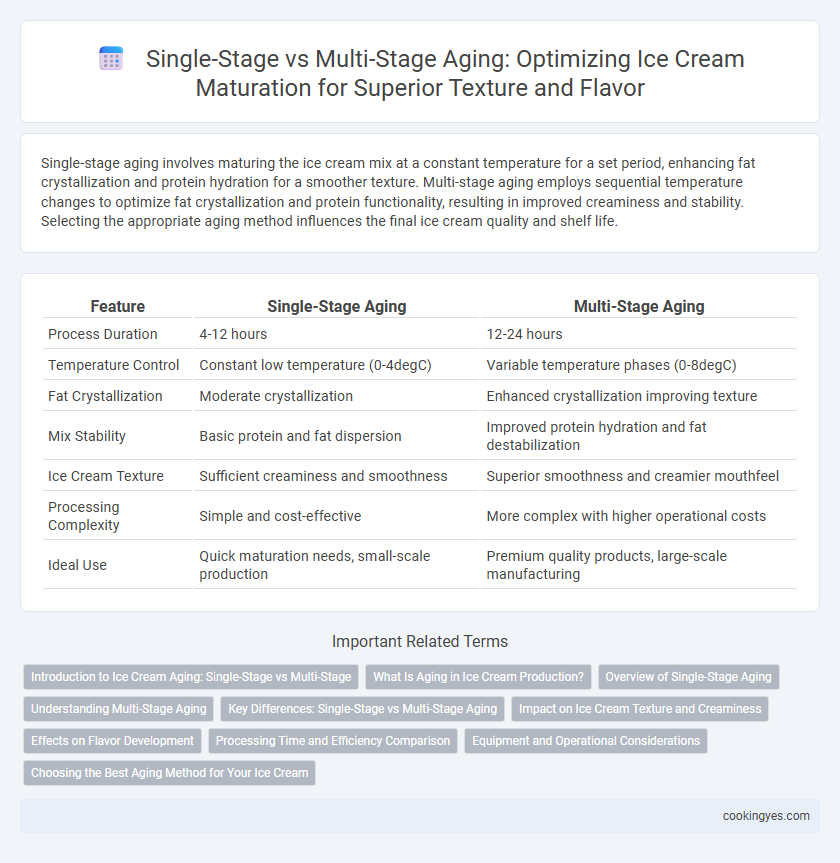

Table of Comparison

| Feature | Single-Stage Aging | Multi-Stage Aging |

|---|---|---|

| Process Duration | 4-12 hours | 12-24 hours |

| Temperature Control | Constant low temperature (0-4degC) | Variable temperature phases (0-8degC) |

| Fat Crystallization | Moderate crystallization | Enhanced crystallization improving texture |

| Mix Stability | Basic protein and fat dispersion | Improved protein hydration and fat destabilization |

| Ice Cream Texture | Sufficient creaminess and smoothness | Superior smoothness and creamier mouthfeel |

| Processing Complexity | Simple and cost-effective | More complex with higher operational costs |

| Ideal Use | Quick maturation needs, small-scale production | Premium quality products, large-scale manufacturing |

Introduction to Ice Cream Aging: Single-Stage vs Multi-Stage

Ice cream aging enhances mix viscosity and stabilizes fat globules, critical for texture development. Single-stage aging involves storing the ice cream mix at low temperatures for a set period, typically 4 to 24 hours, to ensure protein hydration and fat crystallization. Multi-stage aging incorporates additional temperature variations or rest periods, optimizing ice crystal formation and improving overrun and meltdown resistance.

What Is Aging in Ice Cream Production?

Aging in ice cream production refers to the process of holding the ice cream mix at refrigerated temperatures, typically between 4degC and 7degC, allowing fat to partially crystallize and proteins to hydrate, which improves texture and body. Single-stage aging involves one continuous period, usually 4 to 24 hours, enhancing mix viscosity and stabilizing air incorporation for a creamier product. Multi-stage aging separates this into distinct phases, optimizing protein functionality and fat crystallization, resulting in superior overrun control and smoother mouthfeel in the final ice cream.

Overview of Single-Stage Aging

Single-stage aging for ice cream maturation involves maintaining the ice cream mix at a controlled low temperature for a specific period, typically 4 to 24 hours, to enhance fat crystallization and protein hydration. This process improves the mix's viscosity, whipping properties, and final texture, resulting in smoother, creamier ice cream. Single-stage aging is preferred in many commercial applications due to its simplicity and consistent quality outcomes.

Understanding Multi-Stage Aging

Multi-stage aging in ice cream maturation improves fat crystallization and protein hydration through controlled temperature variations, enhancing texture and creaminess. Unlike single-stage aging, which maintains a constant temperature, multi-stage aging cycles between cold and slightly warmer phases to optimize mix stability and air incorporation. This method results in a smoother mouthfeel and better overrun, crucial for premium ice cream quality.

Key Differences: Single-Stage vs Multi-Stage Aging

Single-stage aging involves maintaining the ice cream mix at a specific low temperature for a set duration, typically enhancing fat crystallization and protein hydration uniformly, resulting in a smoother texture. Multi-stage aging introduces varying temperature phases, optimizing different biochemical reactions such as emulsifier distribution and ice crystal size reduction, thereby improving creaminess and stability more effectively. Key differences include the simplicity and shorter time of single-stage aging versus the complex temperature control and enhanced quality benefits found in multi-stage aging processes.

Impact on Ice Cream Texture and Creaminess

Single-stage aging promotes uniform protein hydration and fat crystallization, resulting in a smoother and creamier ice cream texture. Multi-stage aging allows for extended protein stabilization and enhanced fat crystal development, which improves overall scoopability and reduces ice crystal formation. The choice between single-stage and multi-stage aging directly impacts the final ice cream's mouthfeel, creaminess, and structural integrity.

Effects on Flavor Development

Single-stage aging offers a consistent temperature environment that slows fat crystallization, promoting uniform flavor compound distribution in ice cream. Multi-stage aging, involving variable temperatures, enhances enzymatic activities and volatile compound formation, leading to a more complex flavor profile. Research shows that multi-stage aging significantly intensifies taste depth and aroma richness compared to single-stage methods.

Processing Time and Efficiency Comparison

Single-stage aging involves holding the ice cream mix at a controlled temperature for a set period, typically 4 to 24 hours, allowing fat crystallization and protein hydration to improve texture and whipping capacity. Multi-stage aging divides this process into two or more temperature phases, often starting at 0degC and finishing around 4degC, which can enhance stability and overrun but requires more careful monitoring and longer total processing time. Compared to single-stage aging, multi-stage aging offers improved emulsification and smoother texture but reduces overall processing efficiency due to increased complexity and extended maturation duration.

Equipment and Operational Considerations

Single-stage aging for ice cream maturation utilizes simpler equipment, typically requiring a single refrigeration tank, resulting in lower operational complexity and reduced maintenance needs. Multi-stage aging involves multiple tanks or vessels that enable controlled temperature profiles, enhancing texture and overrun uniformity but demanding higher capital investment and more intricate monitoring systems. Equipment choice impacts operational efficiency, with single-stage favoring simplicity and multi-stage enabling precise control crucial for premium product consistency.

Choosing the Best Aging Method for Your Ice Cream

Single-stage aging offers a straightforward process that evenly stabilizes ice cream mix proteins and fat globules, ensuring a consistent texture and flavor profile. Multi-stage aging, involving gradual temperature adjustments, enhances fat crystallization and overrun control, resulting in creamier texture and improved melt resistance. Selecting the optimal aging method depends on desired texture precision, production scale, and equipment capabilities for achieving superior ice cream maturation.

Single-stage vs multi-stage aging for ice cream maturation Infographic

cookingyes.com

cookingyes.com