Batch freezers produce ice cream in small, controlled quantities, allowing for greater flexibility in flavor experimentation and texture customization. Continuous freezers operate by continuously freezing and aerating the mix, enabling high-volume production with consistent quality and smooth texture. Choosing between batch and continuous freezers depends on the desired production scale and the need for product variety versus efficiency.

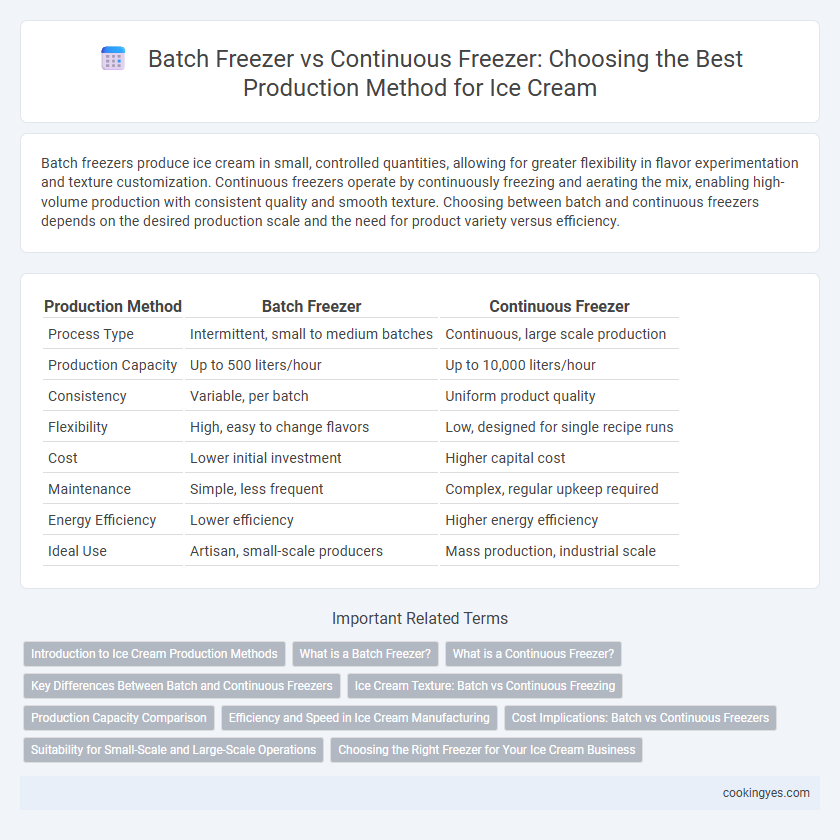

Table of Comparison

| Production Method | Batch Freezer | Continuous Freezer |

|---|---|---|

| Process Type | Intermittent, small to medium batches | Continuous, large scale production |

| Production Capacity | Up to 500 liters/hour | Up to 10,000 liters/hour |

| Consistency | Variable, per batch | Uniform product quality |

| Flexibility | High, easy to change flavors | Low, designed for single recipe runs |

| Cost | Lower initial investment | Higher capital cost |

| Maintenance | Simple, less frequent | Complex, regular upkeep required |

| Energy Efficiency | Lower efficiency | Higher energy efficiency |

| Ideal Use | Artisan, small-scale producers | Mass production, industrial scale |

Introduction to Ice Cream Production Methods

Batch freezers produce ice cream in individual, controlled batches, ensuring precise texture and flavor customization, making them ideal for artisan and small-scale production. Continuous freezers enable high-volume, efficient ice cream manufacturing by freezing mix while simultaneously incorporating air, optimizing throughput for commercial factories. Both methods influence overrun, texture, and production speed, critical parameters in ice cream quality and scalability.

What is a Batch Freezer?

A batch freezer is a production method used in ice cream manufacturing where ingredients are frozen in discrete batches, allowing precise control over texture and consistency. This process typically involves freezing and churning a set quantity of mix before the machine is emptied and reloaded for the next batch, ideal for small-scale or artisanal production. Batch freezers enable customization of flavors and add-ins while maintaining high-quality ice cream with a creamy, smooth texture.

What is a Continuous Freezer?

A continuous freezer is a high-efficiency ice cream production machine that continuously processes and freezes the ice cream mix, allowing for large-scale, consistent output with precise control over overrun and texture. Unlike batch freezers, it maintains a steady flow of product, optimizing production speed and uniformity, which is essential for commercial ice cream manufacturing. This method improves productivity and reduces processing time while delivering smooth, high-quality ice cream.

Key Differences Between Batch and Continuous Freezers

Batch freezers produce small quantities of ice cream at a time with controlled consistency and flavor customization, making them ideal for artisanal and small-scale production. Continuous freezers operate with a nonstop process, allowing large-scale production and higher efficiency by freezing and whipping the ice cream mix simultaneously. The primary differences lie in production volume, flexibility in recipe adjustments, and operational speed, with batch freezers favoring variety and quality, while continuous freezers emphasize quantity and uniformity.

Ice Cream Texture: Batch vs Continuous Freezing

Batch freezers produce ice cream with a creamier and denser texture by freezing small quantities at a time, allowing for better control over air incorporation and crystallization. Continuous freezers enable high-volume production with consistent texture but typically yield lighter, less dense ice cream due to constant freezing and higher overrun. The choice between batch and continuous freezing directly impacts mouthfeel and creaminess, critical factors in consumer preference.

Production Capacity Comparison

Batch freezers typically produce ice cream in smaller quantities, ranging from 5 to 30 liters per cycle, making them ideal for artisanal or small-scale production. Continuous freezers offer significantly higher production capacity, processing hundreds to thousands of liters per hour, suitable for large-scale industrial manufacturing. The choice between batch and continuous freezers depends on desired output volume, with continuous freezers providing superior efficiency and scalability for mass production.

Efficiency and Speed in Ice Cream Manufacturing

Batch freezers offer precise control over small-scale ice cream production, ensuring high-quality texture but with slower output rates. Continuous freezers excel in large-scale manufacturing by rapidly processing high volumes, maximizing efficiency and reducing production time. Choosing between these depends on desired production capacity and speed requirements in ice cream manufacturing.

Cost Implications: Batch vs Continuous Freezers

Batch freezers involve lower initial capital investment and are suited for small to medium-scale ice cream production, resulting in cost savings for limited output runs. Continuous freezers require higher upfront costs but offer greater efficiency and lower per-unit production costs at large scales due to automation and faster freezing cycles. Choosing between batch and continuous freezers depends on production volume, with batch models minimizing fixed costs and continuous models maximizing economies of scale.

Suitability for Small-Scale and Large-Scale Operations

Batch freezers offer flexibility and control for small-scale ice cream production, allowing precise ingredient customization and small quantity batches. Continuous freezers are designed for large-scale operations, providing high efficiency and consistent output through uninterrupted processing. The choice depends on production volume needs, with batch freezers ideal for artisanal products and continuous freezers suited for mass production.

Choosing the Right Freezer for Your Ice Cream Business

Batch freezers offer superior control over texture and flavor customization, ideal for artisanal ice cream production with smaller volumes. Continuous freezers enable high-volume production with consistent quality and faster output, suitable for large-scale commercial operations. Selecting the right freezer depends on balancing production capacity, desired product consistency, and operational efficiency to meet business goals.

Batch freezer vs Continuous freezer for Production Method Infographic

cookingyes.com

cookingyes.com