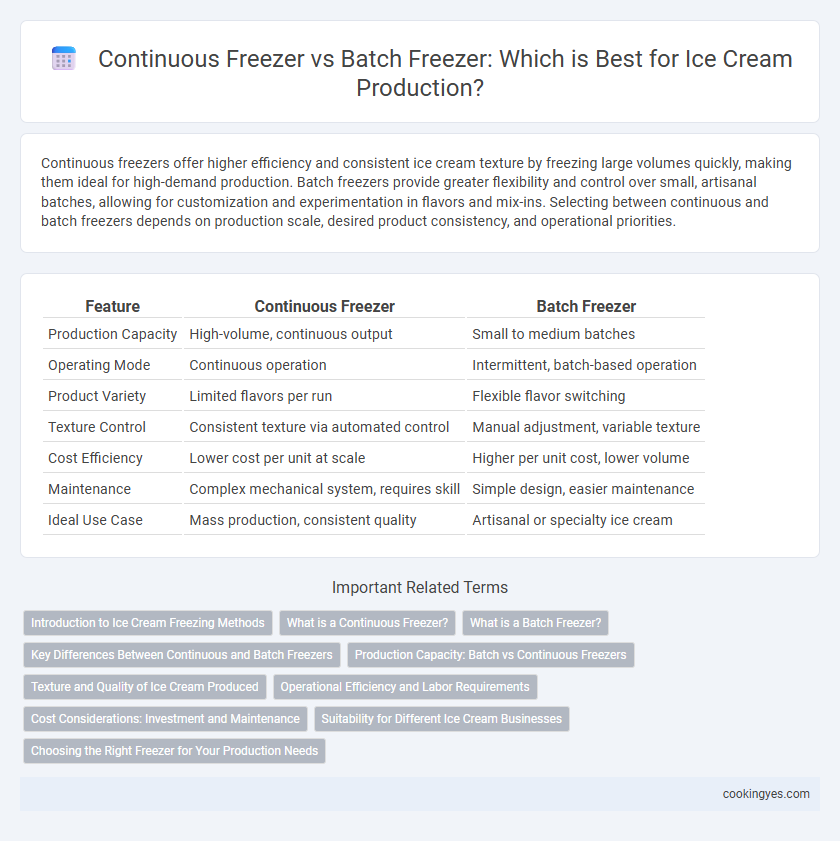

Continuous freezers offer higher efficiency and consistent ice cream texture by freezing large volumes quickly, making them ideal for high-demand production. Batch freezers provide greater flexibility and control over small, artisanal batches, allowing for customization and experimentation in flavors and mix-ins. Selecting between continuous and batch freezers depends on production scale, desired product consistency, and operational priorities.

Table of Comparison

| Feature | Continuous Freezer | Batch Freezer |

|---|---|---|

| Production Capacity | High-volume, continuous output | Small to medium batches |

| Operating Mode | Continuous operation | Intermittent, batch-based operation |

| Product Variety | Limited flavors per run | Flexible flavor switching |

| Texture Control | Consistent texture via automated control | Manual adjustment, variable texture |

| Cost Efficiency | Lower cost per unit at scale | Higher per unit cost, lower volume |

| Maintenance | Complex mechanical system, requires skill | Simple design, easier maintenance |

| Ideal Use Case | Mass production, consistent quality | Artisanal or specialty ice cream |

Introduction to Ice Cream Freezing Methods

Continuous freezers enable high-volume ice cream production by rapidly freezing and simultaneously incorporating air, achieving consistent texture and overrun in a streamlined process. Batch freezers freeze smaller quantities of mix in discrete cycles, offering greater control over ingredients and customization for artisanal or specialty ice cream flavors. Understanding the differences in freezing methods is essential for selecting the ideal equipment based on production scale, product consistency, and texture requirements.

What is a Continuous Freezer?

A continuous freezer is a specialized industrial machine designed for high-volume ice cream production, enabling the constant freezing and simultaneous incorporation of air into the mix, resulting in consistent product texture and quality. Unlike batch freezers that process smaller quantities in individual cycles, continuous freezers maintain uninterrupted operation, maximizing efficiency and output in commercial ice cream manufacturing. This equipment is essential for large-scale producers aiming to meet demand while ensuring uniformity in overrun, viscosity, and temperature control.

What is a Batch Freezer?

A batch freezer is a specialized ice cream production machine designed to freeze and simultaneously churn small quantities of ice cream mix, creating a smooth and creamy texture. Unlike continuous freezers, batch freezers process one batch at a time, allowing precise control over texture, flavor infusion, and overrun (air incorporation). This equipment is ideal for artisanal or small-scale ice cream producers seeking high-quality, customizable results.

Key Differences Between Continuous and Batch Freezers

Continuous freezers produce ice cream by continuously mixing and freezing the mix, allowing for higher volume output and consistent product texture, making them ideal for large-scale production. Batch freezers operate in discrete cycles, producing smaller quantities with greater control over texture and overrun, suitable for artisanal or specialty ice cream products. Key differences include production capacity, with continuous freezers offering efficiency and consistency, while batch freezers provide customization and flexibility in flavor and texture variations.

Production Capacity: Batch vs Continuous Freezers

Continuous freezers offer significantly higher production capacity by processing ice cream mix in a steady, uninterrupted flow, ideal for large-scale manufacturing. Batch freezers produce smaller quantities per cycle, providing flexibility for artisanal or small-batch ice cream production but limiting output volume. The choice between continuous and batch freezers directly impacts throughput efficiency and scalability in ice cream manufacturing operations.

Texture and Quality of Ice Cream Produced

Continuous freezers produce ice cream with a smoother, more consistent texture due to the constant freezing and mixing process, which incorporates uniform air distribution known as overrun. Batch freezers allow for greater control over small production runs, resulting in artisanal textures with varied creaminess and denser mouthfeel due to slower freezing cycles. The choice between continuous and batch freezers impacts ice cream quality by balancing mass production efficiency against customization of texture and richness.

Operational Efficiency and Labor Requirements

Continuous freezers offer higher operational efficiency by producing ice cream nonstop, reducing downtime and maximizing throughput compared to batch freezers. They require less labor due to automation and consistent processing, allowing streamlined production lines with minimal manual intervention. Batch freezers provide flexibility for small batches but demand more labor-intensive oversight and longer cycle times, limiting scalability in high-volume production.

Cost Considerations: Investment and Maintenance

Continuous freezers require a higher initial investment compared to batch freezers but offer greater production efficiency and lower labor costs over time. Batch freezers have lower upfront costs, making them suitable for small-scale ice cream production, but they demand more frequent maintenance and manual intervention. Maintenance costs for continuous freezers tend to be lower due to their automated processes, while batch freezers may incur higher expenses from wear and tear on individual components.

Suitability for Different Ice Cream Businesses

Continuous freezers are ideal for large-scale ice cream producers seeking high-volume, consistent output with efficient energy use, making them suitable for commercial factories and mass production. Batch freezers offer flexibility and small-batch quality control, perfect for artisanal ice cream businesses and specialty shops aiming to create unique flavors and textures. The choice between continuous and batch freezers depends on production volume, product variety, and business scale.

Choosing the Right Freezer for Your Production Needs

Selecting the right freezer for ice cream production depends on output volume and product consistency requirements. Continuous freezers offer high-capacity, efficient production with consistent quality ideal for large-scale manufacturing, while batch freezers provide flexibility and control, making them suitable for small-batch or artisanal ice cream. Evaluating production scale, desired texture, and operational budget ensures optimal equipment choice for maximizing efficiency and product quality.

Continuous Freezer vs Batch Freezer for Production Infographic

cookingyes.com

cookingyes.com