Hand-rolled spring rolls offer a unique texture and personalized touch, allowing for greater control over ingredient distribution and tenderness. Machine-rolled spring rolls provide consistency and speed, ideal for large-scale production without compromising on uniformity. Choosing between hand-rolled and machine-rolled methods depends on the balance of artisanal quality versus efficiency required for spring roll preparation.

Table of Comparison

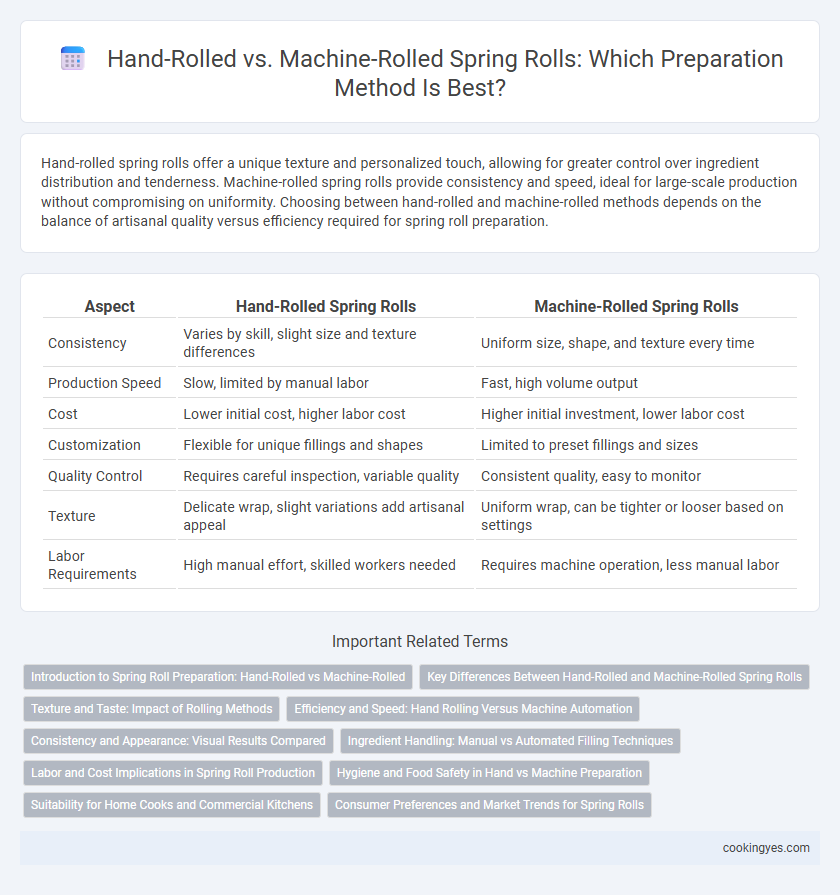

| Aspect | Hand-Rolled Spring Rolls | Machine-Rolled Spring Rolls |

|---|---|---|

| Consistency | Varies by skill, slight size and texture differences | Uniform size, shape, and texture every time |

| Production Speed | Slow, limited by manual labor | Fast, high volume output |

| Cost | Lower initial cost, higher labor cost | Higher initial investment, lower labor cost |

| Customization | Flexible for unique fillings and shapes | Limited to preset fillings and sizes |

| Quality Control | Requires careful inspection, variable quality | Consistent quality, easy to monitor |

| Texture | Delicate wrap, slight variations add artisanal appeal | Uniform wrap, can be tighter or looser based on settings |

| Labor Requirements | High manual effort, skilled workers needed | Requires machine operation, less manual labor |

Introduction to Spring Roll Preparation: Hand-Rolled vs Machine-Rolled

Hand-rolled spring rolls showcase artisanal craftsmanship, offering delicate texture and customizable fillings that enhance flavor complexity. Machine-rolled spring rolls provide consistent size and shape, boosting production efficiency and uniformity in commercial settings. Choosing between hand-rolled and machine-rolled methods impacts texture, taste, and scalability in spring roll preparation.

Key Differences Between Hand-Rolled and Machine-Rolled Spring Rolls

Hand-rolled spring rolls offer a unique texture and customizable thickness due to the artisan technique, ensuring each roll maintains a delicate, crispy exterior with a perfectly balanced filling. Machine-rolled spring rolls provide uniform size and shape, increasing production speed and consistency, ideal for large-scale manufacturing. The choice between hand-rolled and machine-rolled methods directly impacts flavor concentration, texture variation, and overall presentation quality of the final spring roll product.

Texture and Taste: Impact of Rolling Methods

Hand-rolled spring rolls offer a distinct texture characterized by uneven layers and a more artisanal crunch, which enhances the overall eating experience. Machine-rolled spring rolls typically provide uniform thickness and tight wrapping, resulting in a more consistent taste and texture but sometimes sacrificing the delicate crispiness. The choice between hand-rolled and machine-rolled methods significantly influences flavor absorption and mouthfeel, with hand-rolling often delivering a richer, more authentic taste profile.

Efficiency and Speed: Hand Rolling Versus Machine Automation

Hand-rolled spring rolls offer meticulous control over ingredient placement and texture, ideal for artisanal quality but are labor-intensive and slower in production. Machine-rolled spring rolls significantly boost efficiency and speed by automating the rolling process, enabling consistent size and shape with high throughput suitable for large-scale manufacturing. Automation reduces manual labor costs and accelerates output, making it the preferred choice for commercial operations demanding fast volume without sacrificing uniformity.

Consistency and Appearance: Visual Results Compared

Hand-rolled spring rolls often display variations in size and shape, resulting in a more artisanal and rustic appearance but inconsistent consistency. Machine-rolled spring rolls achieve uniform size and tightly sealed edges, ensuring consistent cooking and presentation, ideal for large-scale production. The precise control of machinery leads to evenly cooked spring rolls with a polished, professional look that enhances visual appeal on any menu.

Ingredient Handling: Manual vs Automated Filling Techniques

Hand-rolled spring rolls allow for precise ingredient handling, enabling cooks to adjust filling quantities and distribution based on texture and taste. Machine-rolled spring rolls utilize automated filling techniques that ensure consistent portion control and uniformity, improving production speed and reducing waste. Both methods influence the freshness and texture of the filling, with manual techniques offering customization and automation prioritizing efficiency.

Labor and Cost Implications in Spring Roll Production

Hand-rolled spring rolls require significant labor hours, increasing production costs due to skilled workforce demands and slower output rates. Machine-rolled spring rolls streamline the preparation process, reducing labor expenses and boosting efficiency with consistent product quality. However, initial investment in automated equipment can be substantial, impacting upfront capital allocation for manufacturers.

Hygiene and Food Safety in Hand vs Machine Preparation

Hand-rolled spring rolls pose a higher risk of contamination due to direct human contact, increasing the chances of bacterial transfer if proper hygiene protocols are not strictly followed. Machine-rolled spring rolls offer enhanced food safety by minimizing human touchpoints and enabling standardized, sanitized production environments. Consistent machine processing ensures uniform hygiene standards, reducing potential foodborne illness compared to hand-prepared alternatives.

Suitability for Home Cooks and Commercial Kitchens

Hand-rolled spring rolls offer greater control over filling distribution and texture, making them ideal for home cooks who prioritize customization and traditional preparation methods. Machine-rolled spring rolls provide consistent size and shape, significantly increasing production speed and efficiency, thus better suiting commercial kitchens with high-volume demands. For home use, hand-rolling enhances authenticity and flexibility, while machine rolling streamlines operations in fast-paced foodservice environments.

Consumer Preferences and Market Trends for Spring Rolls

Hand-rolled spring rolls are favored by consumers seeking authenticity and artisanal quality, often associated with fresh ingredients and a handmade texture that appeals to niche markets. Machine-rolled spring rolls cater to mass production demands, offering consistency, speed, and cost efficiency, which align with large-scale retail and fast-food industry needs. Market trends indicate a growing preference for premium, handcrafted products in gourmet and health-conscious segments, while convenience-driven markets continue to dominate with machine-rolled options.

Hand-rolled vs Machine-rolled for spring roll preparation Infographic

cookingyes.com

cookingyes.com