Hand-rolled spring rolls offer a traditional, artisanal texture and unique shape with each roll, enhancing flavor through careful craftsmanship. Machine-rolled spring rolls provide consistent size and speed, ideal for large-scale production and uniform cooking. Choosing between hand-rolled and machine-rolled depends on the desired balance of authenticity and efficiency.

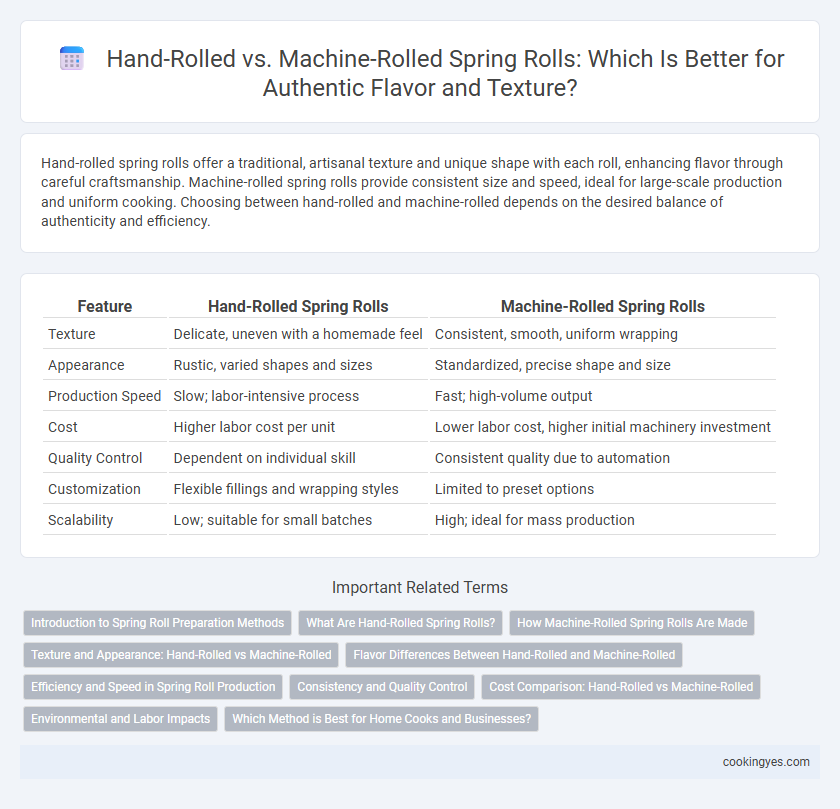

Table of Comparison

| Feature | Hand-Rolled Spring Rolls | Machine-Rolled Spring Rolls |

|---|---|---|

| Texture | Delicate, uneven with a homemade feel | Consistent, smooth, uniform wrapping |

| Appearance | Rustic, varied shapes and sizes | Standardized, precise shape and size |

| Production Speed | Slow; labor-intensive process | Fast; high-volume output |

| Cost | Higher labor cost per unit | Lower labor cost, higher initial machinery investment |

| Quality Control | Dependent on individual skill | Consistent quality due to automation |

| Customization | Flexible fillings and wrapping styles | Limited to preset options |

| Scalability | Low; suitable for small batches | High; ideal for mass production |

Introduction to Spring Roll Preparation Methods

Hand-rolled spring rolls offer a delicate texture and personalized craftsmanship, often resulting in a crispier exterior and more evenly distributed filling. Machine-rolled spring rolls provide consistent size and shape, enhancing production speed and uniformity for large batches. Each preparation method reflects distinct culinary techniques that impact the final taste and presentation of the spring roll.

What Are Hand-Rolled Spring Rolls?

Hand-rolled spring rolls are crafted individually using fresh ingredients wrapped in thin, delicate rice paper or wheat wrappers by skilled artisans. This traditional method allows for greater control over the filling distribution and wrapper tightness, resulting in a crispier texture and more authentic taste. Hand-rolled varieties often feature vibrant, layered flavors and retain higher visual appeal, setting them apart from machine-rolled counterparts.

How Machine-Rolled Spring Rolls Are Made

Machine-rolled spring rolls are produced using automated conveyor belts and rollers that evenly press thin dough sheets into uniform wrappers, ensuring consistent thickness and shape. The mechanized process speeds up production, increasing efficiency and maintaining a standardized product quality across large batches. This automated precision minimizes human error and reduces labor costs while providing wrappers that are ideal for commercial spring roll preparation.

Texture and Appearance: Hand-Rolled vs Machine-Rolled

Hand-rolled spring rolls feature a delicate, uneven texture with slightly varied thickness, creating a rustic appearance and a satisfying bite. Machine-rolled spring rolls offer consistent thickness and uniform shapes, resulting in a polished look and evenly crisp texture. Texture variation in hand-rolled versions often enhances the overall sensory experience, while machine-rolled rolls prioritize aesthetic precision and consistency.

Flavor Differences Between Hand-Rolled and Machine-Rolled

Hand-rolled spring rolls often have a more delicate texture and uneven wrapping that enhances the overall flavor complexity by allowing the ingredients to meld naturally. Machine-rolled spring rolls provide consistent thickness and tight wrapping, which can result in a slightly firmer texture but may reduce the subtle layers of taste developed in hand-rolled versions. The artisanal nature of hand-rolling captures subtle variations in ingredient balance and moisture, leading to a richer flavor experience compared to the uniformity of machine-rolled spring rolls.

Efficiency and Speed in Spring Roll Production

Hand-rolled spring rolls offer artisanal quality with delicate, customizable folds but are time-consuming and limit production speed. Machine-rolled spring rolls dramatically increase efficiency by producing consistent rolls at a rapid pace, ideal for large-scale manufacturing. Automated rolling reduces labor costs and maintains uniformity, making it the preferred choice for high-volume spring roll production.

Consistency and Quality Control

Hand-rolled spring rolls often vary in size and tightness, leading to inconsistent texture and cooking quality, whereas machine-rolled spring rolls ensure uniformity in shape and filling distribution, improving consistency across batches. Automated rolling processes allow for precise quality control by minimizing human error and enhancing production speed, crucial for large-scale manufacturing. Consistent roll tightness achieved by machines also prevents oil seepage during frying, maintaining product integrity and customer satisfaction.

Cost Comparison: Hand-Rolled vs Machine-Rolled

Hand-rolled spring rolls typically incur higher labor costs due to the time-intensive manual process, resulting in increased overall expenses for small-scale producers or specialty markets. Machine-rolled spring rolls offer significant cost savings through faster production speeds and consistent quality, reducing labor hours and minimizing waste. Bulk manufacturing environments benefit most from machine-rolled options, where economies of scale further drive down per-unit costs compared to hand-rolled counterparts.

Environmental and Labor Impacts

Hand-rolled spring rolls significantly reduce energy consumption compared to machine-rolled ones, lowering the overall carbon footprint of production. This artisanal method supports local labor markets by providing employment opportunities and preserving traditional skills, fostering community livelihoods. Conversely, machine-rolled spring rolls increase industrial energy use and often favor automation over human labor, potentially contributing to job displacement and higher environmental costs.

Which Method is Best for Home Cooks and Businesses?

Hand-rolled spring rolls offer a unique texture and customization that appeal to home cooks seeking authenticity and control over ingredient distribution, while machine-rolled spring rolls provide consistent size and faster production ideal for businesses aiming to scale efficiently. For home cooks, hand-rolling enhances the culinary experience and allows personalized fillings, making each roll distinct and fresh. Businesses benefit from machine rolling by meeting high demand with uniform products, reducing labor costs, and maintaining quality standards in bulk production.

Hand-rolled vs machine-rolled for spring rolls Infographic

cookingyes.com

cookingyes.com