Hand-churned ice cream offers a richer texture and more control over ingredients, appealing to those seeking a traditional and artisanal approach. Machine-churned ice cream provides consistency, faster production, and convenience, making it ideal for larger batches and commercial use. Choosing between the two depends on the desired texture, flavor intensity, and production scale.

Table of Comparison

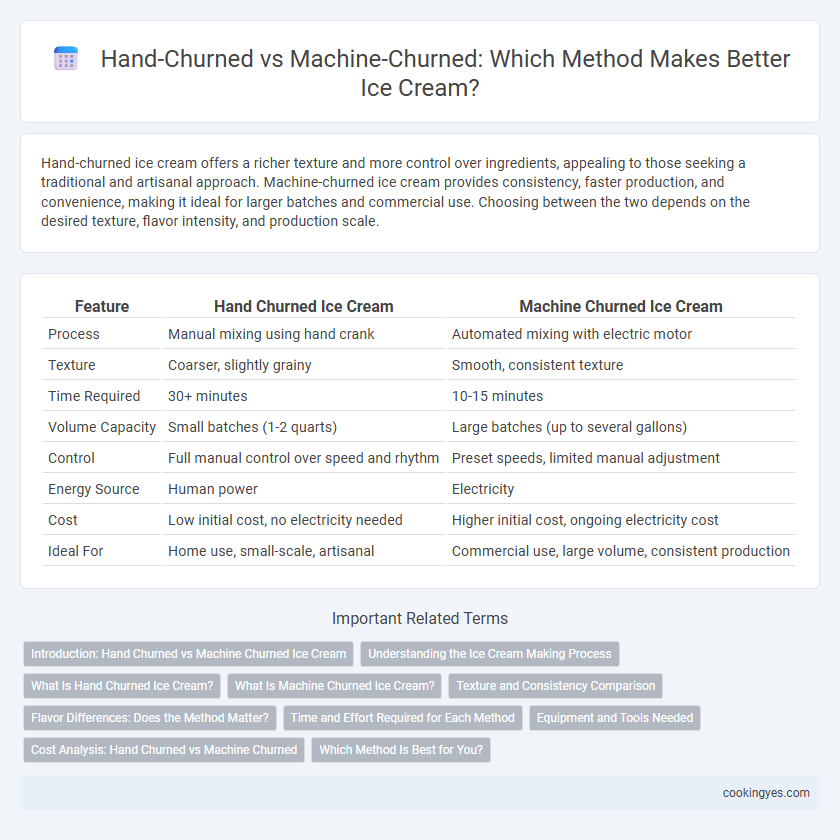

| Feature | Hand Churned Ice Cream | Machine Churned Ice Cream |

|---|---|---|

| Process | Manual mixing using hand crank | Automated mixing with electric motor |

| Texture | Coarser, slightly grainy | Smooth, consistent texture |

| Time Required | 30+ minutes | 10-15 minutes |

| Volume Capacity | Small batches (1-2 quarts) | Large batches (up to several gallons) |

| Control | Full manual control over speed and rhythm | Preset speeds, limited manual adjustment |

| Energy Source | Human power | Electricity |

| Cost | Low initial cost, no electricity needed | Higher initial cost, ongoing electricity cost |

| Ideal For | Home use, small-scale, artisanal | Commercial use, large volume, consistent production |

Introduction: Hand Churned vs Machine Churned Ice Cream

Hand churned ice cream preserves traditional methods by slowly mixing and freezing the base using manual rotary churns, resulting in dense texture and rich flavor from gradual incorporation of air. Machine churned ice cream employs automated mixers that rapidly blend and freeze the mixture, ensuring consistent texture and faster production suitable for commercial volumes. Both methods influence the creaminess, air content (overrun), and overall sensory experience, making the choice essential for artisanal versus mass-produced ice cream.

Understanding the Ice Cream Making Process

Hand churned ice cream involves manually rotating a dasher inside a container to slowly freeze the mixture, which creates larger ice crystals and results in a denser, creamier texture. Machine churned ice cream uses electric motors to churn at higher speeds, producing smaller ice crystals that yield a smoother and lighter consistency. Understanding these differences helps in choosing the ideal method for achieving preferred texture and creaminess in homemade or artisanal ice cream.

What Is Hand Churned Ice Cream?

Hand churned ice cream is crafted by manually rotating a spindle or crank to mix the ice cream base, which incorporates air slowly, resulting in a denser and creamier texture compared to machine churned varieties. This traditional method often uses natural ingredients and allows for greater control over the texture and flavor development during the freezing process. The slower churning speed prevents large ice crystals from forming, enhancing the smoothness of hand churned ice cream.

What Is Machine Churned Ice Cream?

Machine churned ice cream is produced using automated equipment that rapidly stirs and freezes the mixture, incorporating air to create a smooth and consistent texture. This method allows for precise temperature control and faster production compared to traditional hand churning. Industrial ice cream makers often use continuous freezers that enhance efficiency and ensure uniform quality in large-scale manufacturing.

Texture and Consistency Comparison

Hand churned ice cream typically features a denser, creamier texture due to slower churning that minimizes air incorporation, resulting in a richer mouthfeel. Machine churned ice cream often achieves a lighter, smoother consistency by rapidly mixing ingredients and incorporating more air, known as overrun, which increases volume and softness. Differences in texture and consistency between hand churned and machine churned ice cream significantly impact sensory experience, with hand churned offering a traditional, artisanal quality and machine churned providing uniformity and ease of production.

Flavor Differences: Does the Method Matter?

Hand churned ice cream typically offers a richer, creamier texture with more pronounced natural flavors due to slower freezing, which allows larger ice crystals to form and enhances mouthfeel. Machine churned ice cream often results in a smoother, more consistent texture with less air incorporation, providing a uniform flavor distribution but sometimes lacking the depth found in hand churned variants. The churning method influences flavor intensity and texture, making taste preferences vary between artisanal and mass-produced ice creams.

Time and Effort Required for Each Method

Hand churned ice cream demands significant time and physical effort, often requiring 20 to 40 minutes of continuous manual cranking to achieve the desired texture. Machine churned ice cream is much faster and less labor-intensive, typically completing the freezing and mixing process within 20 to 30 minutes with minimal user intervention. The mechanical consistency of machine churners ensures uniform churning efficiency compared to the variable speed and stamina limitations in hand churning.

Equipment and Tools Needed

Hand churned ice cream requires basic equipment such as a wooden or metal churn, dasher, and a container for freezing, relying on manual labor to agitate the mixture. Machine churned ice cream involves electric or motorized ice cream makers with built-in motors and cooling systems, allowing for faster and more consistent churning. The choice of equipment directly impacts texture, production time, and batch size, with machine churners offering greater efficiency and less physical effort.

Cost Analysis: Hand Churned vs Machine Churned

Hand churned ice cream requires minimal equipment investment but demands significant labor time, making it cost-effective only for small-scale or artisanal production. Machine churned ice cream involves higher upfront costs for commercial churners and ongoing expenses for electricity and maintenance but enables large-scale, consistent output that lowers per-unit cost. Evaluating fixed versus variable costs highlights machine churning as more economical for bulk production, while hand churning suits niche markets valuing craftsmanship over volume.

Which Method Is Best for You?

Hand churned ice cream offers a traditional, artisanal texture with a denser, creamier consistency due to slower freezing and less air incorporation. Machine churned ice cream provides convenience, faster production, and consistent texture, ideal for larger batches or commercial use. Choosing the best method depends on your preference for authenticity and texture versus speed and volume.

Hand churned vs Machine churned for ice cream making Infographic

cookingyes.com

cookingyes.com