LTLT pasteurization, also known as low-temperature long-time pasteurization, heats the ice cream mix at 145degF for 30 minutes, ensuring thorough pathogen elimination while preserving the creamy texture. HTST pasteurization rapidly heats the mix to 161degF for 15 seconds, providing faster processing and effective microbial control but may slightly alter flavor profiles. Choosing between LTLT and HTST impacts ice cream safety, taste, and production efficiency, with both methods meeting regulatory standards for pathogen reduction.

Table of Comparison

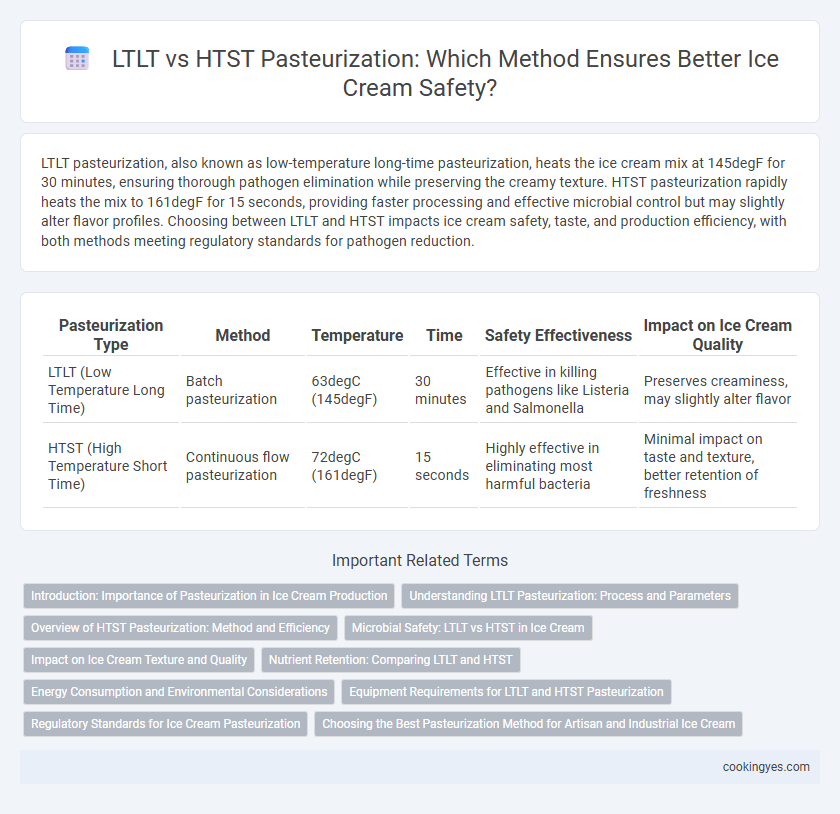

| Pasteurization Type | Method | Temperature | Time | Safety Effectiveness | Impact on Ice Cream Quality |

|---|---|---|---|---|---|

| LTLT (Low Temperature Long Time) | Batch pasteurization | 63degC (145degF) | 30 minutes | Effective in killing pathogens like Listeria and Salmonella | Preserves creaminess, may slightly alter flavor |

| HTST (High Temperature Short Time) | Continuous flow pasteurization | 72degC (161degF) | 15 seconds | Highly effective in eliminating most harmful bacteria | Minimal impact on taste and texture, better retention of freshness |

Introduction: Importance of Pasteurization in Ice Cream Production

Pasteurization is essential in ice cream production to eliminate harmful pathogens such as Listeria monocytogenes and Salmonella, ensuring product safety and extending shelf life. Low Temperature Long Time (LTLT) pasteurization (typically 63degC for 30 minutes) offers thorough microbial reduction but is less efficient compared to High Temperature Short Time (HTST) pasteurization, which heats the mix to 72degC for 15 seconds. HTST pasteurization maintains the sensory qualities of ice cream while providing rapid, consistent pathogen control required by food safety regulations.

Understanding LTLT Pasteurization: Process and Parameters

LTLT pasteurization in ice cream production involves heating the mix at 63degC (145degF) for 30 minutes, ensuring effective pathogen elimination while preserving the product's creamy texture and flavor. This method uses a lower temperature and longer time compared to HTST pasteurization, which typically heats the mix at 72degC (161degF) for 15 seconds, balancing microbial safety with taste retention. Understanding LTLT parameters is essential for maintaining ice cream safety standards while achieving desired sensory qualities.

Overview of HTST Pasteurization: Method and Efficiency

HTST pasteurization involves heating ice cream mix to at least 161degF (72degC) for 15 seconds, effectively destroying harmful pathogens such as Listeria and Salmonella while preserving flavor and texture. This method offers efficient microbial reduction compared to LTLT pasteurization, which heats at lower temperatures for longer times. HTST's rapid heating and cooling process enhances production speed and ensures consistent safety standards in commercial ice cream manufacturing.

Microbial Safety: LTLT vs HTST in Ice Cream

LTLT (Low Temperature Long Time) pasteurization heats ice cream mixtures to 63degC for 30 minutes, ensuring effective inactivation of pathogenic microbes such as Listeria monocytogenes and Salmonella while preserving flavor. HTST (High Temperature Short Time) pasteurization rapidly heats the mixture to 72degC for 15 seconds, achieving faster microbial kill rates and reducing contamination risk with minimal impact on sensory qualities. HTST offers superior microbial safety in ice cream production due to its efficiency in eliminating heat-resistant bacteria and spores compared to LTLT.

Impact on Ice Cream Texture and Quality

LTLT pasteurization (Low-Temperature Long-Time) gently heats ice cream mix at 145degF for 30 minutes, preserving the milk proteins that contribute to a creamier, smoother texture. HTST pasteurization (High-Temperature Short-Time) heats the mix at 161degF for 15 seconds, which can cause slight protein denaturation, potentially affecting ice cream's body and overrun. LTLT enhances creaminess and richness, while HTST offers faster processing but may yield a slightly less velvety mouthfeel.

Nutrient Retention: Comparing LTLT and HTST

LTLT pasteurization preserves more vitamins and delicate nutrients in ice cream by using lower temperatures over a longer time, reducing nutrient degradation. HTST pasteurization, while effective at rapidly eliminating pathogens, can cause more significant losses of heat-sensitive nutrients due to higher temperatures applied briefly. Choosing LTLT enhances nutrient retention but requires precise control to ensure safety standards for ice cream production.

Energy Consumption and Environmental Considerations

LTLT pasteurization, operating at lower temperatures for longer durations, consumes more energy compared to HTST pasteurization, which uses higher temperatures for shorter times, making HTST more energy-efficient for ice cream production. HTST pasteurization reduces the carbon footprint by minimizing fuel or electricity usage, contributing to more sustainable ice cream manufacturing processes. Environmental considerations favor HTST due to its lower operational energy demand and decreased greenhouse gas emissions associated with faster processing cycles.

Equipment Requirements for LTLT and HTST Pasteurization

LTLT (Low Temperature Long Time) pasteurization for ice cream requires simpler equipment, typically a batch pasteurizer with precise temperature control and extended holding times around 145degF for 30 minutes, making it suitable for smaller-scale production. HTST (High Temperature Short Time) pasteurization involves more complex heat exchangers and continuous flow systems that rapidly heat ice cream mix to about 161degF for 15 seconds, enabling higher throughput and better energy efficiency. Equipment for HTST pasteurization demands more stringent maintenance and calibration to ensure safety compliance and minimize microbial risks in large-scale ice cream manufacturing.

Regulatory Standards for Ice Cream Pasteurization

LTLT (Low-Temperature Long-Time) pasteurization, typically conducted at 63degC for 30 minutes, meets regulatory standards for ice cream safety by effectively eliminating pathogens without compromising texture. HTST (High-Temperature Short-Time) pasteurization, performed at 72degC for 15 seconds, is widely accepted by food safety authorities like the FDA and European Food Safety Authority due to its efficiency in microbial reduction and preservation of product quality. Compliance with these pasteurization methods ensures ice cream meets stringent microbial limits set forth in Codex Alimentarius and regional dairy safety regulations.

Choosing the Best Pasteurization Method for Artisan and Industrial Ice Cream

LTLT (Low-Temperature Long-Time) pasteurization, typically at 63degC for 30 minutes, preserves the delicate flavors and artisanal qualities of ice cream by minimizing heat damage while ensuring safety. HTST (High-Temperature Short-Time) pasteurization, operating at 72degC for 15 seconds, offers faster processing and higher microbial kill rates ideal for industrial-scale production and extended shelf life. Choosing between LTLT and HTST depends on balancing product quality with production efficiency, where artisan producers may prefer LTLT for premium taste and industrial manufacturers rely on HTST for consistent safety and volume.

LTLT pasteurization vs HTST pasteurization for ice cream safety Infographic

cookingyes.com

cookingyes.com