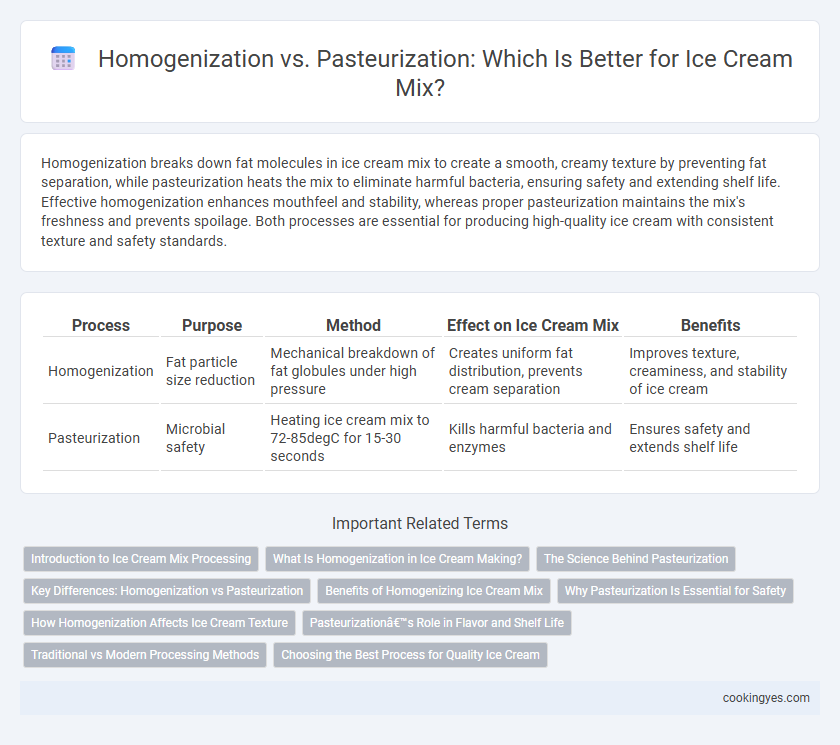

Homogenization breaks down fat molecules in ice cream mix to create a smooth, creamy texture by preventing fat separation, while pasteurization heats the mix to eliminate harmful bacteria, ensuring safety and extending shelf life. Effective homogenization enhances mouthfeel and stability, whereas proper pasteurization maintains the mix's freshness and prevents spoilage. Both processes are essential for producing high-quality ice cream with consistent texture and safety standards.

Table of Comparison

| Process | Purpose | Method | Effect on Ice Cream Mix | Benefits |

|---|---|---|---|---|

| Homogenization | Fat particle size reduction | Mechanical breakdown of fat globules under high pressure | Creates uniform fat distribution, prevents cream separation | Improves texture, creaminess, and stability of ice cream |

| Pasteurization | Microbial safety | Heating ice cream mix to 72-85degC for 15-30 seconds | Kills harmful bacteria and enzymes | Ensures safety and extends shelf life |

Introduction to Ice Cream Mix Processing

Homogenization in ice cream mix processing breaks down fat globules to create a smooth, creamy texture and prevent fat separation, enhancing overall product stability. Pasteurization involves heating the mix to eliminate harmful pathogens and extend shelf life without compromising nutritional value or flavor. Both processes are essential: pasteurization ensures safety, while homogenization improves consistency and mouthfeel in the final ice cream product.

What Is Homogenization in Ice Cream Making?

Homogenization in ice cream making is a mechanical process that breaks down fat molecules in the ice cream mix to create a uniform and stable emulsion, preventing fat separation and improving texture. This process enhances creaminess by ensuring smaller fat globules are evenly dispersed, resulting in a smoother mouthfeel. Homogenization is essential for achieving consistent quality and maximizing the mix's ability to trap air during freezing, contributing to better volume and softness.

The Science Behind Pasteurization

Pasteurization in ice cream mix involves heating the mixture to a specific temperature, typically around 72degC (161degF), for 15 seconds to eliminate pathogenic bacteria and ensure safety. This thermal process not only destroys harmful microorganisms but also denatures whey proteins, improving the mix's texture and stability during freezing. Homogenization, on the other hand, mechanically reduces fat globule size to prevent cream separation, but pasteurization is crucial for microbiological safety and enhancing the overall quality of the ice cream base.

Key Differences: Homogenization vs Pasteurization

Homogenization in ice cream mix breaks down fat globules into smaller sizes to create a smooth, creamy texture, while pasteurization involves heating the mix to eliminate harmful bacteria and ensure safety. Homogenization affects the physical consistency and mouthfeel by evenly distributing fat, whereas pasteurization primarily targets microbial stability and extends shelf life. Both processes are critical, but homogenization enhances texture whereas pasteurization guarantees product safety.

Benefits of Homogenizing Ice Cream Mix

Homogenizing ice cream mix breaks down fat globules into smaller sizes, resulting in a smoother, creamier texture and improved mouthfeel. This process enhances the stability of the ice cream, preventing fat separation and creating a more consistent product during freezing. Homogenization also improves the incorporation of air, boosting volume and overall sensory appeal.

Why Pasteurization Is Essential for Safety

Pasteurization is essential for ice cream safety because it eliminates harmful pathogens such as Listeria monocytogenes, Salmonella, and E. coli from the ice cream mix by heating it to a specific temperature for a designated time. Unlike homogenization, which mainly improves texture by breaking down fat globules, pasteurization ensures microbial safety by destroying disease-causing bacteria and extending shelf life. This critical process complies with food safety regulations and prevents foodborne illnesses associated with dairy-based ice cream products.

How Homogenization Affects Ice Cream Texture

Homogenization breaks down fat globules in the ice cream mix, creating a smoother and creamier texture by preventing fat separation. This process enhances the uniformity of the ice cream body, leading to improved mouthfeel and richness. Pasteurization, while essential for eliminating harmful bacteria, primarily ensures safety without significantly altering texture.

Pasteurization’s Role in Flavor and Shelf Life

Pasteurization in ice cream mix involves heating the mixture to eliminate harmful bacteria, which significantly enhances flavor development by stabilizing the base ingredients and preventing spoilage. This process extends shelf life by reducing microbial load, ensuring consistent taste and texture over time. Proper pasteurization safeguards product quality, making it essential for maintaining the safety and longevity of ice cream.

Traditional vs Modern Processing Methods

Traditional ice cream processing relies on basic pasteurization to eliminate pathogens and homogenization to evenly distribute fat globules, ensuring a smoother texture. Modern methods employ advanced ultra-high-temperature (UHT) pasteurization and high-pressure homogenization, resulting in improved microbial safety and enhanced creaminess. These innovations optimize the ice cream mix's consistency and shelf life while preserving flavor integrity.

Choosing the Best Process for Quality Ice Cream

Homogenization breaks down fat globules in the ice cream mix to create a smooth, creamy texture, while pasteurization eliminates harmful bacteria by heating the mixture to a specific temperature. Selecting the best process involves balancing texture enhancement from homogenization with safety assurance from pasteurization, as both are essential for premium quality ice cream. Effective pasteurization combined with proper homogenization ensures a consistent, safe, and enjoyable frozen dessert experience.

Homogenization vs pasteurization for ice cream mix Infographic

cookingyes.com

cookingyes.com