Retarded fermentation enhances croissant flavor by allowing yeast to develop slowly at low temperatures, producing deeper, more complex aromas and a tender crumb. Direct fermentation accelerates the process, resulting in a milder taste and less nuanced texture. Bakers aiming for rich, layered flavors prefer retarded fermentation despite longer preparation times.

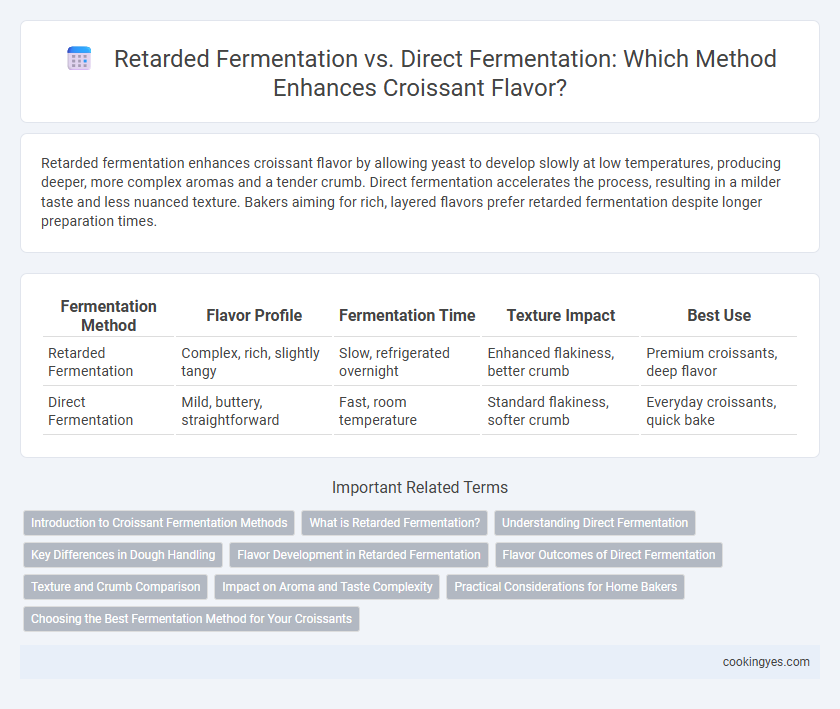

Table of Comparison

| Fermentation Method | Flavor Profile | Fermentation Time | Texture Impact | Best Use |

|---|---|---|---|---|

| Retarded Fermentation | Complex, rich, slightly tangy | Slow, refrigerated overnight | Enhanced flakiness, better crumb | Premium croissants, deep flavor |

| Direct Fermentation | Mild, buttery, straightforward | Fast, room temperature | Standard flakiness, softer crumb | Everyday croissants, quick bake |

Introduction to Croissant Fermentation Methods

Retarded fermentation involves prolonged proofing at low temperatures, enhancing the croissant's flavor complexity and texture by allowing yeast enzymes to develop more nuanced aromas and a tender crumb. Direct fermentation accelerates the process, producing a lighter, less developed flavor profile but enabling faster production and consistent results. Both methods impact the croissant's final taste and texture, with retarded fermentation favored for artisanal qualities and direct fermentation preferred in commercial bakeries for efficiency.

What is Retarded Fermentation?

Retarded fermentation is a technique in croissant making where the dough is fermented slowly at low temperatures, typically in a refrigerator for 12 to 24 hours. This slow fermentation enhances flavor complexity by allowing yeast to develop organic acids and alcohol, resulting in a more nuanced, buttery taste and improved texture. In contrast to direct fermentation, which uses faster, room-temperature rising, retarded fermentation creates a deeper, richer flavor profile prized by artisanal bakers.

Understanding Direct Fermentation

Direct fermentation in croissant dough enhances flavor by accelerating yeast activity, producing a more pronounced, fresh yeast aroma compared to retarded fermentation. This method involves mixing all ingredients and allowing the dough to ferment at room temperature, resulting in a shorter fermentation time and a lighter, more airy crumb structure. Bakers aiming for a balanced buttery taste and delicate texture often prefer direct fermentation for its consistent and predictable flavor profile.

Key Differences in Dough Handling

Retarded fermentation involves slow proofing of croissant dough at low temperatures, enhancing flavor complexity through extended yeast activity and enzymatic development. Direct fermentation, by contrast, uses a quicker proofing process at warmer temperatures, resulting in less time for flavor maturation but faster production. Key differences in dough handling include temperature control, fermentation duration, and yeast activity management, which directly impact the final flavor profile and texture of the croissant.

Flavor Development in Retarded Fermentation

Retarded fermentation significantly enhances croissant flavor by slowing yeast activity at low temperatures, allowing complex organic acids and alcohols to develop, which contribute to a richer and more nuanced taste profile. This extended fermentation process improves the dough's enzymatic activity, increasing maltose and amino acid production that intensifies buttery and caramel notes. In contrast to direct fermentation, retarded fermentation results in a superior depth of flavor and aroma, making croissants more distinctive and palatable.

Flavor Outcomes of Direct Fermentation

Direct fermentation in croissant dough accelerates yeast activity, resulting in a more pronounced and robust buttery aroma with a slightly tangy undertone. This method produces a lighter, flakier texture while preserving the natural sweetness of the flour, enhancing overall flavor complexity. Bakers seeking a quicker process often choose direct fermentation to achieve consistent and vibrant flavor profiles without the extended fermentation time of retarded methods.

Texture and Crumb Comparison

Retarded fermentation enhances croissant texture by allowing slow yeast activity, resulting in a flakier, more layered crumb with improved aroma complexity. Direct fermentation produces a softer, less structured crumb due to rapid proofing, often sacrificing the characteristic lightness associated with traditional croissants. Emphasizing retarded fermentation yields superior dough extensibility and a crispier outer crust, optimizing the signature delicate texture.

Impact on Aroma and Taste Complexity

Retarded fermentation in croissant dough enhances aroma and taste complexity by allowing yeast and enzymes to develop flavors slowly at low temperatures, producing subtle fruity and nutty notes. Direct fermentation accelerates the process, resulting in a milder flavor profile with less pronounced aromatic compounds. The extended cold fermentation promotes the formation of organic acids and alcohols, significantly enriching the croissant's buttery, slightly tangy taste.

Practical Considerations for Home Bakers

Retarded fermentation in croissant dough involves refrigerating the dough for an extended period, enhancing flavor complexity by allowing organic acids and enzymes to develop gradually. Direct fermentation accelerates the process but may result in less depth of flavor and a denser crumb. Home bakers benefit from retarded fermentation by improving dough handling flexibility and flavor development, though it requires careful temperature control and longer preparation time.

Choosing the Best Fermentation Method for Your Croissants

Retarded fermentation enhances croissant flavor by allowing slow yeast activity at low temperatures, producing complex aromas and a delicate crumb texture. Direct fermentation offers faster dough development with more straightforward flavor profiles, ideal for quick production schedules. Selecting the best fermentation method depends on balancing desired flavor depth and time constraints to achieve optimal croissant quality.

Retarded Fermentation vs Direct Fermentation for Flavor Infographic

cookingyes.com

cookingyes.com