Roller sheeters ensure consistent dough thickness and uniform lamination, speeding up the croissant-making process while maintaining quality. Hand rolling offers greater control over dough texture and layering, allowing bakers to adjust pressure and technique for artisanal results. Both methods impact the flakiness and rise of croissants, making the choice dependent on desired texture and production scale.

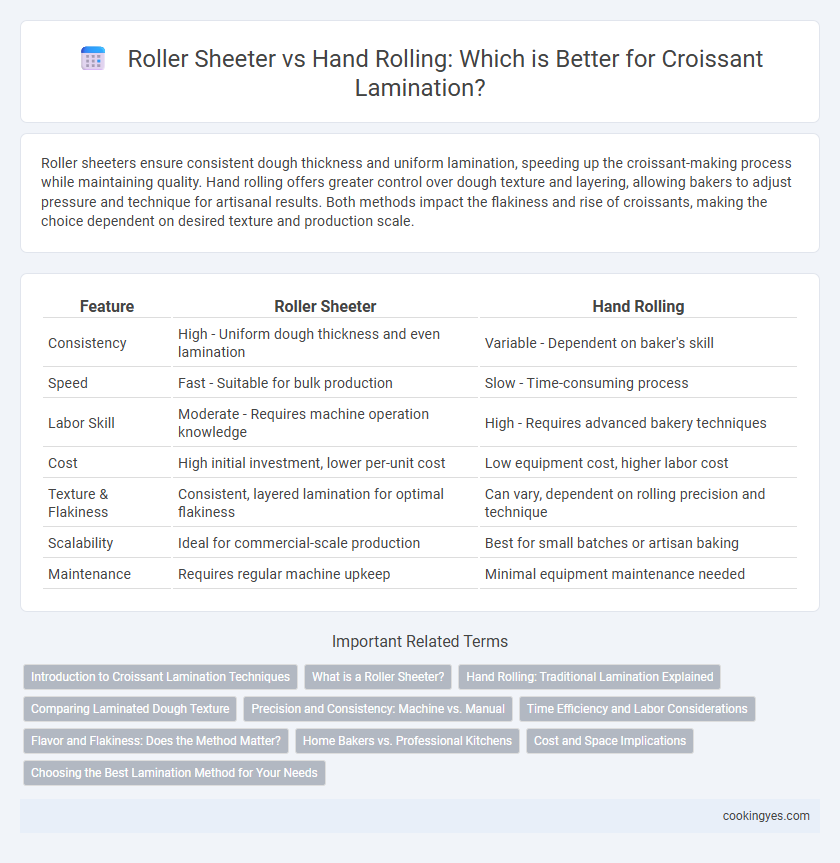

Table of Comparison

| Feature | Roller Sheeter | Hand Rolling |

|---|---|---|

| Consistency | High - Uniform dough thickness and even lamination | Variable - Dependent on baker's skill |

| Speed | Fast - Suitable for bulk production | Slow - Time-consuming process |

| Labor Skill | Moderate - Requires machine operation knowledge | High - Requires advanced bakery techniques |

| Cost | High initial investment, lower per-unit cost | Low equipment cost, higher labor cost |

| Texture & Flakiness | Consistent, layered lamination for optimal flakiness | Can vary, dependent on rolling precision and technique |

| Scalability | Ideal for commercial-scale production | Best for small batches or artisan baking |

| Maintenance | Requires regular machine upkeep | Minimal equipment maintenance needed |

Introduction to Croissant Lamination Techniques

Croissant lamination techniques involve repeatedly folding and rolling dough with layers of butter to create a flaky, airy texture. Roller sheeters provide consistent, uniform dough thickness crucial for efficient lamination, speeding up production while reducing labor. Hand rolling allows artisanal control, offering precision in layer formation but requires significant skill and time to achieve optimal results.

What is a Roller Sheeter?

A roller sheeter is a mechanical device designed to evenly roll and flatten croissant dough during lamination, ensuring consistent thickness and uniform layers. Used in professional bakeries, this equipment automates the dough sheeting process, improving efficiency and precision compared to hand rolling. By controlling dough thickness with adjustable rollers, a roller sheeter enhances lamination quality, resulting in flakier, more uniform croissants.

Hand Rolling: Traditional Lamination Explained

Hand rolling in croissant lamination preserves the artisanal texture by carefully folding and pressing dough with consistent pressure, allowing precise control over butter distribution and dough thickness. This traditional technique enhances the croissant's flaky layers and delicate crumb structure, which can be compromised by mechanical roller sheeters. Master bakers favor hand rolling for its ability to produce superior flavor profiles and authentic textures, essential for high-quality croissants.

Comparing Laminated Dough Texture

Roller sheeters produce consistently thin and even layers in croissant lamination, resulting in a uniform, flaky texture with precise dough thickness that enhances rise and flakiness. Hand rolling allows for more artisanal control but can lead to slight variations in dough thickness and layer spacing, sometimes creating more varied textures and denser spots in the croissant crumb. Choosing between roller sheeting and hand rolling impacts the laminated dough's consistency, flakiness, and overall mouthfeel, influencing the final quality of croissants.

Precision and Consistency: Machine vs. Manual

Roller sheeters provide precise and consistent dough thickness crucial for croissant lamination, ensuring even butter distribution and uniform layer formation. Hand rolling offers tactile control but introduces variability in dough thickness and layer uniformity, potentially affecting the croissant's flakiness and rise. Industrial bakeries prioritize roller sheeters for scalability and repeatability, while artisanal bakers may prefer hand rolling for nuanced texture and craftsmanship.

Time Efficiency and Labor Considerations

Roller sheeters significantly reduce croissant lamination time by uniformly flattening dough layers faster than manual hand rolling, enhancing production efficiency. This mechanized process decreases labor intensity and the physical strain on bakers, enabling consistent thickness and uniform gluten development. While hand rolling allows for artisanal control, roller sheeters optimize time management and scalability in commercial bakery operations.

Flavor and Flakiness: Does the Method Matter?

Roller sheeters provide consistent, even dough thickness that enhances uniform lamination, often resulting in crispier, flakier croissants, but some bakers argue that hand rolling allows for more controlled layering, which can intensify buttery flavor and create delicate, artisanal textures. The mechanical precision of roller sheeters boosts production efficiency without sacrificing flakiness, while hand rolling preserves traditional craftsmanship that highlights complex flavor development through subtle variations in dough handling. Ultimately, the impact on croissant flavor and flakiness depends on skill level and dough quality rather than the lamination method alone.

Home Bakers vs. Professional Kitchens

Roller sheeters provide consistent, thin, and even dough layers essential for perfect croissant lamination, making them ideal for professional kitchens with high production demands. Home bakers often prefer hand rolling for its control and tactile feedback, despite it being more time-consuming and less precise, which can affect the flakiness and rise of the croissant. The choice between roller sheeter and hand rolling directly impacts dough thickness, butter distribution, and final croissant texture, influencing overall quality and baking efficiency in different settings.

Cost and Space Implications

Roller sheeters significantly reduce labor costs and increase production speed compared to hand rolling in croissant lamination, making them ideal for high-volume bakeries. Although roller sheeters require a higher upfront investment and more floor space, they optimize long-term operational efficiency and consistency in dough thickness. Hand rolling demands minimal equipment space and lower initial costs but increases labor time and variability, affecting overall production scalability.

Choosing the Best Lamination Method for Your Needs

Choosing the best lamination method for croissant dough depends on production scale and desired texture. Roller sheeters provide consistent thickness and speed, ideal for commercial bakeries aiming for uniform layers and high volume. Hand rolling offers greater control and artisanal quality, perfect for small batches or bakeries emphasizing traditional craftsmanship.

Roller Sheeter vs Hand Rolling for Croissant Lamination Infographic

cookingyes.com

cookingyes.com