Hand shaping croissants allows for artisanal craftsmanship, offering unique textures and slight variations in each piece that enhance the eating experience. Machine shaping ensures consistent size and uniformity, making it ideal for large-scale production where standardization is critical. Balancing hand shaping's delicate artistry with the precision of machine shaping can optimize both quality and efficiency in croissant production.

Table of Comparison

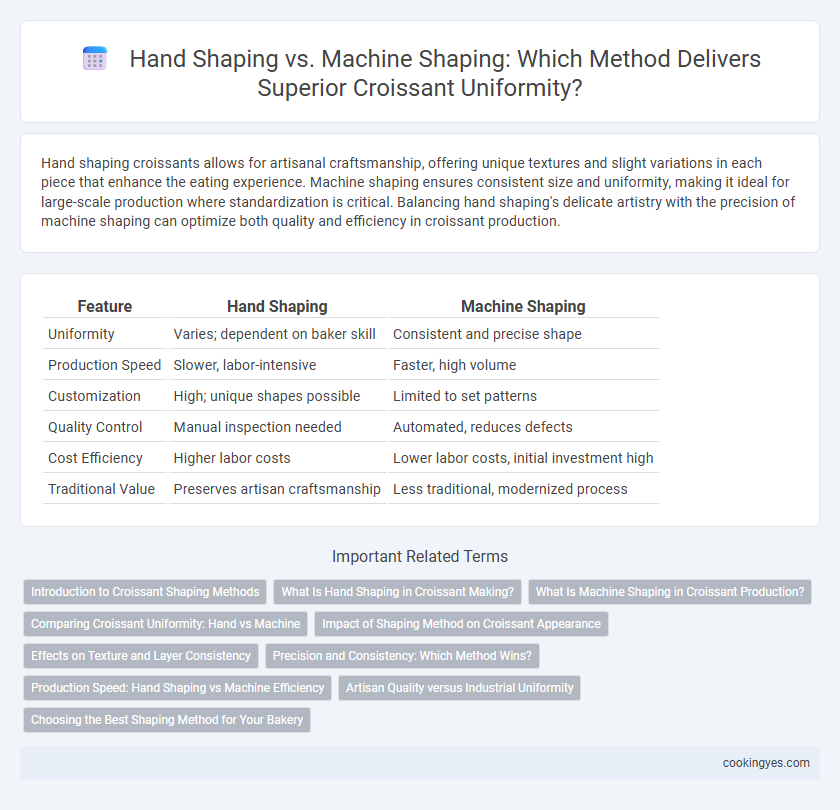

| Feature | Hand Shaping | Machine Shaping |

|---|---|---|

| Uniformity | Varies; dependent on baker skill | Consistent and precise shape |

| Production Speed | Slower, labor-intensive | Faster, high volume |

| Customization | High; unique shapes possible | Limited to set patterns |

| Quality Control | Manual inspection needed | Automated, reduces defects |

| Cost Efficiency | Higher labor costs | Lower labor costs, initial investment high |

| Traditional Value | Preserves artisan craftsmanship | Less traditional, modernized process |

Introduction to Croissant Shaping Methods

Hand shaping croissants allows artisans to carefully control dough tension and layering, resulting in a flaky, tender texture prized by traditional bakers. Machine shaping offers consistent uniformity by standardizing dough size and shape, improving production efficiency in commercial bakeries. Both methods influence croissant appearance and texture, with hand shaping emphasizing craftsmanship and machine shaping prioritizing scalability.

What Is Hand Shaping in Croissant Making?

Hand shaping in croissant making involves manually rolling and folding the dough to achieve the signature flaky layers and crescent shape. This traditional technique allows artisans to control the dough's thickness and texture, enhancing the pastry's tenderness and overall quality. Despite its variability, hand shaping preserves the croissant's authentic craftsmanship and unique appearance.

What Is Machine Shaping in Croissant Production?

Machine shaping in croissant production involves the use of automated equipment to roll, fold, and cut the dough into precise, uniform shapes. This process enhances consistency in size and thickness, ensuring each croissant bakes evenly and maintains a standardized appearance. Industrial bakeries rely on machine shaping to increase efficiency and produce large volumes while reducing human error inherent in hand shaping.

Comparing Croissant Uniformity: Hand vs Machine

Machine shaping of croissants ensures consistent size, thickness, and layering by using precise, automated rollers and cutters, which significantly reduces variability in batch production. Hand shaping, although offering artisanal texture and slight variations that can enhance flakiness and appearance, often results in uneven croissant uniformity due to human inconsistency. For businesses prioritizing uniformity and efficiency, machine shaping delivers more standardized croissants, while hand shaping suits specialty bakeries focused on traditional craftsmanship.

Impact of Shaping Method on Croissant Appearance

Hand shaping croissants results in unique, artisanal variations in flakiness and layering patterns, enhancing visual appeal with subtle imperfections. Machine shaping delivers consistent, uniform croissant shapes and even layering, promoting a standardized appearance ideal for large-scale production. The shaping method directly influences the croissant's external texture, symmetry, and overall aesthetic quality, affecting consumer perception and brand identity.

Effects on Texture and Layer Consistency

Hand shaping croissants allows for delicate control of dough tension, resulting in varied flakiness and a more artisan texture with distinct layers. Machine shaping ensures uniformity in size and layer consistency, producing croissants with a more consistent crumb and even lamination. Texture differences arise as hand-shaped croissants often have irregular, crispier edges, while machine-shaped ones feature a uniformly tender bite throughout.

Precision and Consistency: Which Method Wins?

Hand shaping croissants offers artisanal precision with subtle variations that highlight craftsmanship, while machine shaping delivers unmatched consistency and uniformity essential for large-scale production. Precision in machine shaping ensures each croissant meets exact dimensions and weight specifications, minimizing product variance and enhancing visual appeal. For businesses prioritizing scalability and standardization, machine shaping prevails, whereas boutique bakeries may value the nuanced texture and irregular charm of hand-shaped croissants.

Production Speed: Hand Shaping vs Machine Efficiency

Machine shaping croissants significantly enhances production speed by automating repetitive motions, achieving uniformity across large batches with minimal variance. Hand shaping, while offering artisanal craftsmanship and delicate textural nuances, is inherently slower and less consistent due to human variability. For high-volume bakeries, machine efficiency ensures rapid output without compromising the structural integrity essential for flaky layers.

Artisan Quality versus Industrial Uniformity

Hand shaping croissants allows artisans to create unique layers and textures, enhancing flavor complexity and preserving traditional craftsmanship. Machine shaping delivers consistent size and uniformity critical for large-scale production, ensuring efficiency and standardization. Artisan quality focuses on individuality and texture nuances, while industrial uniformity prioritizes precise replication and volume output.

Choosing the Best Shaping Method for Your Bakery

Hand shaping croissants offers artisanal quality with distinctive flakiness and unique texture variations, favored by high-end bakeries aiming for craftsmanship and flavor depth. Machine shaping ensures consistent size and uniformity, boosting efficiency and reducing labor costs, ideal for large-scale production or chains requiring standardization. Selecting the best shaping method depends on bakery goals: prioritize hand shaping for premium, small-batch croissants or machine shaping for speed and volume without compromising acceptable quality.

Hand Shaping vs Machine Shaping for Croissant Uniformity Infographic

cookingyes.com

cookingyes.com