Hand-rolling croissants delivers a unique artisanal touch, allowing bakers precise control over dough thickness and layering, which can enhance flakiness and texture. In contrast, using a sheeter machine offers consistent thickness and speed, improving efficiency for large batches but may sacrifice some delicate, handcrafted quality. Choosing between hand-rolling and machine sheeting depends on the balance of craftsmanship and production volume desired in croissant making.

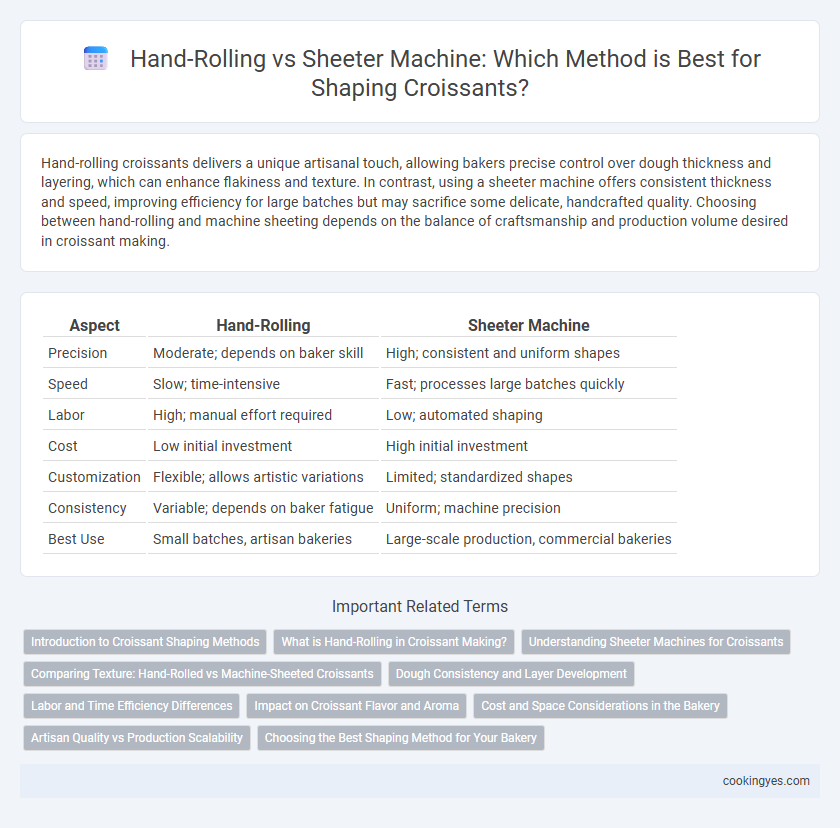

Table of Comparison

| Aspect | Hand-Rolling | Sheeter Machine |

|---|---|---|

| Precision | Moderate; depends on baker skill | High; consistent and uniform shapes |

| Speed | Slow; time-intensive | Fast; processes large batches quickly |

| Labor | High; manual effort required | Low; automated shaping |

| Cost | Low initial investment | High initial investment |

| Customization | Flexible; allows artistic variations | Limited; standardized shapes |

| Consistency | Variable; depends on baker fatigue | Uniform; machine precision |

| Best Use | Small batches, artisan bakeries | Large-scale production, commercial bakeries |

Introduction to Croissant Shaping Methods

Hand-rolling croissants involves skilled artisans manually shaping each dough layer to create the signature flaky texture and delicate layers. Sheeter machines automate the rolling and folding process, ensuring uniform thickness and consistent results in high-volume production. Both methods impact the final crumb structure, flavor development, and overall quality of the croissant, with hand-rolling offering artisanal detail and sheeting providing efficiency.

What is Hand-Rolling in Croissant Making?

Hand-rolling in croissant making involves manually shaping dough into precise crescent forms, allowing bakers to control thickness, texture, and layers more expertly. This traditional method enhances flakiness and creates an artisanal quality that machines sometimes cannot replicate. Skilled hand-rolling also adjusts pressure and folding techniques to optimize gluten development and butter distribution within each croissant.

Understanding Sheeter Machines for Croissants

Sheeter machines for croissants efficiently roll dough to a consistent thickness, enhancing uniformity and reducing manual labor compared to hand-rolling. These machines use adjustable rollers to precisely control dough thickness, ensuring optimal lamination critical for the croissant's flaky texture. Automation through sheeters improves production speed and scalability while maintaining delicate layers essential for high-quality croissants.

Comparing Texture: Hand-Rolled vs Machine-Sheeted Croissants

Hand-rolled croissants exhibit a uniquely flaky texture with more irregular layers, creating a tender crumb and artisanal appeal. Machine-sheeted croissants offer consistent, uniform layering that results in a more even, denser crumb structure. This textural difference stems from the precision and pressure control in machine sheeting versus the variability and delicate handling of hand-rolling dough.

Dough Consistency and Layer Development

Hand-rolling croissants allows greater control over dough consistency, ensuring a delicate balance of elasticity and moisture essential for optimal lamination. Sheeter machines provide uniform sheet thickness, promoting consistent layer development but may risk overworking the dough, leading to tightened gluten and less flakiness. Precise dough temperature management and technique adjustments are critical to achieving the ideal croissant texture regardless of the shaping method.

Labor and Time Efficiency Differences

Hand-rolling croissants demands significant manual labor and time, requiring skilled artisans to meticulously shape each piece for optimal texture and flakiness. Sheeter machines expedite the process by uniformly rolling dough sheets, significantly reducing labor costs and production time while ensuring consistent thickness. Although machines boost efficiency for large batches, hand-rolling preserves traditional craftsmanship valued in artisanal bakeries.

Impact on Croissant Flavor and Aroma

Hand-rolling croissants enhances flavor and aroma by preserving delicate dough layers and allowing subtle air incorporation, which creates a more complex texture and rich buttery notes. In contrast, sheeter machines can compress the dough unevenly, potentially leading to a denser crumb and muted aromatic qualities. Artisanal hand-rolling maintains the integrity of yeast fermentation, resulting in a distinctive, fresh-baked aroma that industrial processes often fail to replicate.

Cost and Space Considerations in the Bakery

Hand-rolling croissants requires minimal equipment investment and occupies less space, making it cost-effective for small bakeries with limited kitchen area. In contrast, sheeter machines demand higher upfront costs and larger footprint but increase production speed and consistency, benefiting high-volume bakeries. Balancing these factors depends on the bakery's scale, budget constraints, and space availability.

Artisan Quality vs Production Scalability

Hand-rolling croissants preserves artisan quality by allowing precise control over dough thickness and layering, resulting in a flakier texture and distinct buttery layers. Sheeter machines enhance production scalability by rapidly flattening dough with consistent thickness, enabling higher volume output while sacrificing some hand-crafted nuances. Balancing traditional hand-rolling techniques with mechanized sheeting helps bakeries meet demand without compromising the signature croissant quality.

Choosing the Best Shaping Method for Your Bakery

Hand-rolling croissants offers artisanal precision and unique texture variations prized by gourmet bakeries, while sheeter machines provide consistent, high-volume shaping essential for large-scale production. Bakers should evaluate their bakery's scale, desired product quality, and labor resources to determine the optimal method. Incorporating sheeter machines enhances efficiency but may sacrifice some handcrafted authenticity, whereas hand-rolling preserves traditional craftsmanship at the cost of higher labor intensity.

Hand-rolling vs sheeter machine for croissant shaping Infographic

cookingyes.com

cookingyes.com