Hand-rolled bagels offer a unique texture and artisanal quality, with each piece exhibiting slight variations that enhance the overall flavor and chewiness. Machine-rolled bagels provide consistency and efficiency, producing uniform shapes and sizes ideal for large-scale production. Choosing between hand-rolled and machine-rolled methods impacts the final bagel's texture, appearance, and production speed.

Table of Comparison

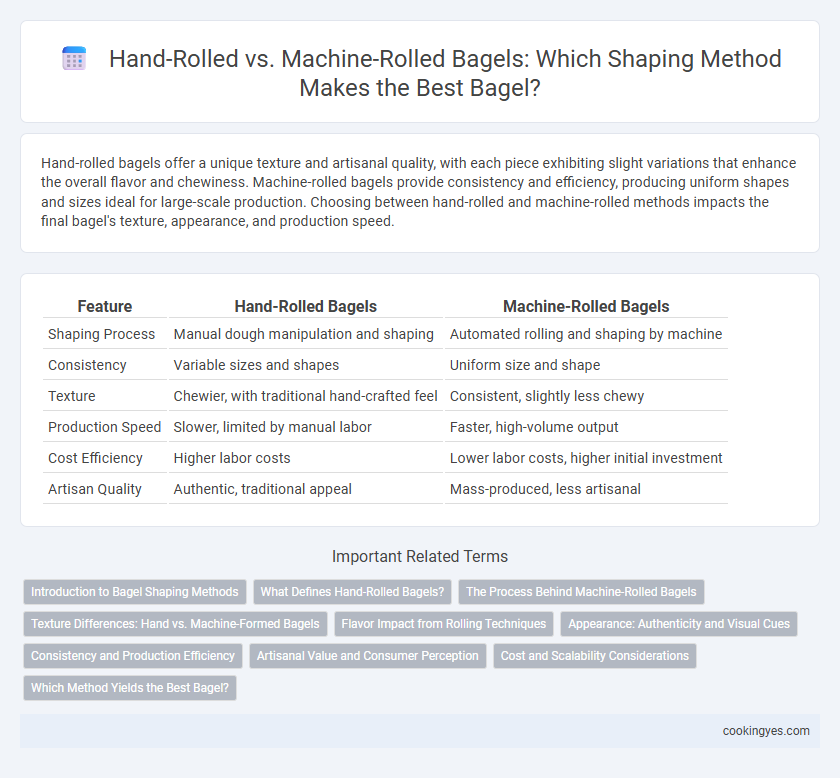

| Feature | Hand-Rolled Bagels | Machine-Rolled Bagels |

|---|---|---|

| Shaping Process | Manual dough manipulation and shaping | Automated rolling and shaping by machine |

| Consistency | Variable sizes and shapes | Uniform size and shape |

| Texture | Chewier, with traditional hand-crafted feel | Consistent, slightly less chewy |

| Production Speed | Slower, limited by manual labor | Faster, high-volume output |

| Cost Efficiency | Higher labor costs | Lower labor costs, higher initial investment |

| Artisan Quality | Authentic, traditional appeal | Mass-produced, less artisanal |

Introduction to Bagel Shaping Methods

Hand-rolled bagels offer a traditional texture with a denser crumb and a chewier bite, achieved through manual shaping that allows precise control over dough tension. Machine-rolled bagels provide consistency in size and shape, streamlining production in commercial settings while maintaining uniformity in crust and crumb structure. The choice between hand-rolled and machine-rolled shaping impacts bagel texture, appearance, and baking characteristics, influencing final product quality.

What Defines Hand-Rolled Bagels?

Hand-rolled bagels are defined by their artisanal shaping process, where skilled bakers manually roll and form each dough ball into a distinctive ring, ensuring a denser texture and chewier crust. This traditional method preserves the bagel's signature bite and allows subtle variations in shape and size, reflecting craftsmanship. Unlike machine-rolled bagels, hand-rolled versions often exhibit a more authentic, rustic appearance and enhanced flavor due to careful handling and fermentation control.

The Process Behind Machine-Rolled Bagels

Machine-rolled bagels are shaped through automated processes that ensure uniformity and consistent size across batches, enhancing production efficiency. The dough is fed into rollers and shaping machines that apply precise pressure to form the classic bagel ring, reducing manual labor and minimizing human error. This mechanized approach speeds up production while maintaining the chewy texture and dense crumb characteristic of traditional bagels.

Texture Differences: Hand vs. Machine-Formed Bagels

Hand-rolled bagels typically feature a denser, chewier texture due to the uneven pressure applied during shaping, which helps retain a traditional bite and a distinct crust. Machine-formed bagels tend to have a more uniform texture with a slightly softer crumb, as the consistent shaping process can reduce the dough's elasticity. Texture differences between hand and machine-formed bagels significantly impact the eating experience, with hand-rolled bagels preferred for artisanal qualities and machine-rolled variants favored for consistency.

Flavor Impact from Rolling Techniques

Hand-rolled bagels develop a denser, chewier texture with a more complex flavor profile due to the uneven pressure and natural variations in dough density. Machine-rolled bagels offer consistency in shape and size but often lack the artisanal touch that enhances the fermentation process and gluten structure. This difference in rolling technique directly influences the final taste and mouthfeel, making hand-rolled bagels preferred for authentic flavor.

Appearance: Authenticity and Visual Cues

Hand-rolled bagels exhibit a distinct, uneven texture and slight irregularities in shape that signal traditional craftsmanship and authenticity. Machine-rolled bagels offer uniform size and smoothness, often lacking the artisanal visual cues prized by bagel enthusiasts. The subtle imperfections in hand-rolled bagels serve as a visual hallmark of genuine, handmade quality.

Consistency and Production Efficiency

Machine-rolled bagels offer superior consistency in shape and size, ensuring uniform baking and a reliable product presentation. Hand-rolled bagels, while allowing for artisanal variations and unique textures, often result in slight inconsistencies that can affect baking times and appearance. Production efficiency is significantly higher with machine-rolling, enabling faster throughput and reduced labor costs, ideal for large-scale operations.

Artisanal Value and Consumer Perception

Hand-rolled bagels exhibit unique texture and irregularities that highlight artisanal craftsmanship, resonating with consumers who seek authenticity and quality in baked goods. Machine-rolled bagels provide uniformity and efficiency but may lack the rustic charm and perceived value associated with traditional methods. Consumer perception often favors hand-rolled bagels as a symbol of artisanal dedication and superior taste, influencing purchasing decisions in premium markets.

Cost and Scalability Considerations

Hand-rolled bagels offer artisanal quality but require significant labor costs and time, limiting scalability in large-scale production. Machine-rolled bagels dramatically reduce labor expenses and increase output consistency, making them ideal for mass production and cost efficiency. Businesses must balance the premium appeal of hand-rolling against the scalable, cost-effective advantages of mechanized shaping in meeting demand.

Which Method Yields the Best Bagel?

Hand-rolled bagels offer a dense, chewy texture with a slightly irregular shape that enhances the artisan appeal, while machine-rolled bagels provide uniformity and consistency in size and appearance, essential for commercial production. The choice of shaping method directly impacts the bagel's crumb structure and crust development, with hand-rolling often favored by traditional bakers seeking authenticity. Machine-rolled bagels excel in efficiency and scalability but may lack the nuanced texture that hand-rolled bagels achieve through manual shaping.

Hand-rolled vs machine-rolled for bagel shaping Infographic

cookingyes.com

cookingyes.com