Hot process for ice cream base preparation involves cooking the mixture to pasteurize and dissolve ingredients thoroughly, resulting in a smoother texture and enhanced flavor development. Cold process skips heating, mixing ingredients directly, which preserves fresh flavors but may lead to a grainier texture and requires high-quality ingredients to ensure safety. Choosing between hot and cold processes impacts creaminess and taste, making the method essential for achieving desired ice cream quality.

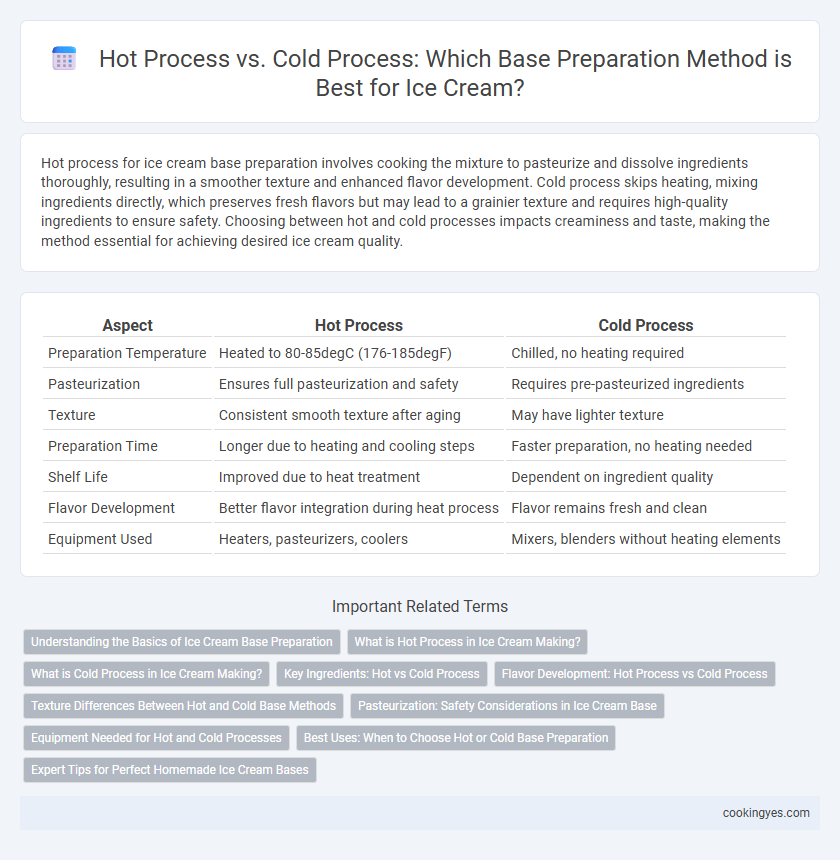

Table of Comparison

| Aspect | Hot Process | Cold Process |

|---|---|---|

| Preparation Temperature | Heated to 80-85degC (176-185degF) | Chilled, no heating required |

| Pasteurization | Ensures full pasteurization and safety | Requires pre-pasteurized ingredients |

| Texture | Consistent smooth texture after aging | May have lighter texture |

| Preparation Time | Longer due to heating and cooling steps | Faster preparation, no heating needed |

| Shelf Life | Improved due to heat treatment | Dependent on ingredient quality |

| Flavor Development | Better flavor integration during heat process | Flavor remains fresh and clean |

| Equipment Used | Heaters, pasteurizers, coolers | Mixers, blenders without heating elements |

Understanding the Basics of Ice Cream Base Preparation

Hot process ice cream base preparation involves heating the mixture of milk, cream, sugar, and stabilizers to dissolve ingredients and ensure pasteurization, which enhances safety and texture. Cold process skips heating and combines ingredients directly, often relying on pre-pasteurized dairy, preserving fresh flavors and reducing preparation time. Choosing between hot and cold processes depends on desired texture, flavor development, and production efficiency in ice cream manufacturing.

What is Hot Process in Ice Cream Making?

Hot process in ice cream making involves heating the ice cream base mixture to pasteurize it, typically between 70degC to 85degC (158degF to 185degF), ensuring safety and improving texture by dissolving sugars and stabilizing proteins. This method enhances flavor development, promotes microbial control, and results in a smoother, more stable final product. Hot process is essential for dairy-based ice creams requiring thorough pasteurization to meet food safety standards.

What is Cold Process in Ice Cream Making?

Cold process in ice cream making involves blending all ingredients directly at low temperatures without pre-cooking, which preserves fresh flavors and reduces preparation time. This method typically uses pasteurized dairy or non-dairy milk, sweeteners, stabilizers, and emulsifiers combined in a chilled mixture before freezing. Cold process ensures a smoother texture and retains the subtle nuances of natural ingredients, making it a preferred technique for artisanal and small-batch ice cream production.

Key Ingredients: Hot vs Cold Process

Hot process base preparation for ice cream involves heating key ingredients such as milk, cream, sugar, and stabilizers to dissolve solids and achieve pasteurization, which enhances texture and safety. Cold process mixes these ingredients without heating, relying on pre-pasteurized components and emulsifiers to ensure smoothness and prevent ice crystal formation. Hot process generally results in a richer, creamier base due to better ingredient integration, while cold process offers convenience with faster preparation and less energy use.

Flavor Development: Hot Process vs Cold Process

Hot process base preparation enhances flavor development by heating ingredients, which intensifies caramelization and Maillard reactions, resulting in richer, more complex taste profiles. Cold process preserves delicate, fresh flavors by avoiding heat, maintaining bright, fruity, and floral notes in ice cream bases. Selecting hot or cold processes significantly impacts the final flavor concentration and overall sensory experience of the ice cream.

Texture Differences Between Hot and Cold Base Methods

Hot process base preparation in ice cream creates a smoother, creamier texture by allowing sugar and egg proteins to fully dissolve and denature, resulting in a stable emulsion. Cold process bases often produce a lighter, airier texture due to minimal protein coagulation and less heating, which preserves delicate flavors but may lead to icier mouthfeel. Understanding these textural distinctions is essential for selecting the appropriate method to achieve the desired creaminess and consistency in premium frozen desserts.

Pasteurization: Safety Considerations in Ice Cream Base

Hot process pasteurization heats the ice cream base to 82degC (180degF) for at least 25 seconds, effectively eliminating harmful bacteria and ensuring microbial safety. Cold process pasteurization, often involving chemical preservatives and rapid chilling, lacks the heat treatment step and may carry higher risks if not properly controlled. Strict temperature monitoring and adherence to pasteurization time are critical in maintaining safety standards and preventing pathogen growth in ice cream bases.

Equipment Needed for Hot and Cold Processes

Hot process base preparation for ice cream requires equipment such as a pasteurizer, cooking kettles, and homogenizers to heat and blend ingredients, ensuring proper pasteurization and texture. Cold process involves simpler equipment, primarily mixers and refrigeration units, as it relies on pre-pasteurized ingredients blended at low temperatures. Pasteurizers are essential for the hot process to achieve safety and stability, while cold process equipment emphasizes efficient chilling and mixing.

Best Uses: When to Choose Hot or Cold Base Preparation

Hot process base preparation is ideal for custard-style ice creams that require cooking egg yolks and sugar to create a rich, creamy texture and enhance flavor development. Cold process is best suited for fruit-flavored or delicate ice creams that benefit from a quick blend without heating, preserving fresh, vibrant tastes and fruit integrity. Choosing between hot or cold base hinges on the desired texture, flavor profile, and ingredient sensitivity to heat during ice cream production.

Expert Tips for Perfect Homemade Ice Cream Bases

Hot process base preparation involves heating cream, milk, sugar, and eggs to create a custard, ensuring a smooth texture and enhanced flavor through proper pasteurization. Cold process bases simplify preparation by mixing ingredients without heating, offering quicker assembly but requiring high-quality pasteurized dairy for food safety and stability. Expert tips for perfect homemade ice cream bases include controlling temperature precisely during the hot process to prevent curdling, using stabilizers like guar gum in cold processes, and aging the base for at least 4 hours to improve texture and flavor integration.

Hot Process vs Cold Process for Base Preparation Infographic

cookingyes.com

cookingyes.com