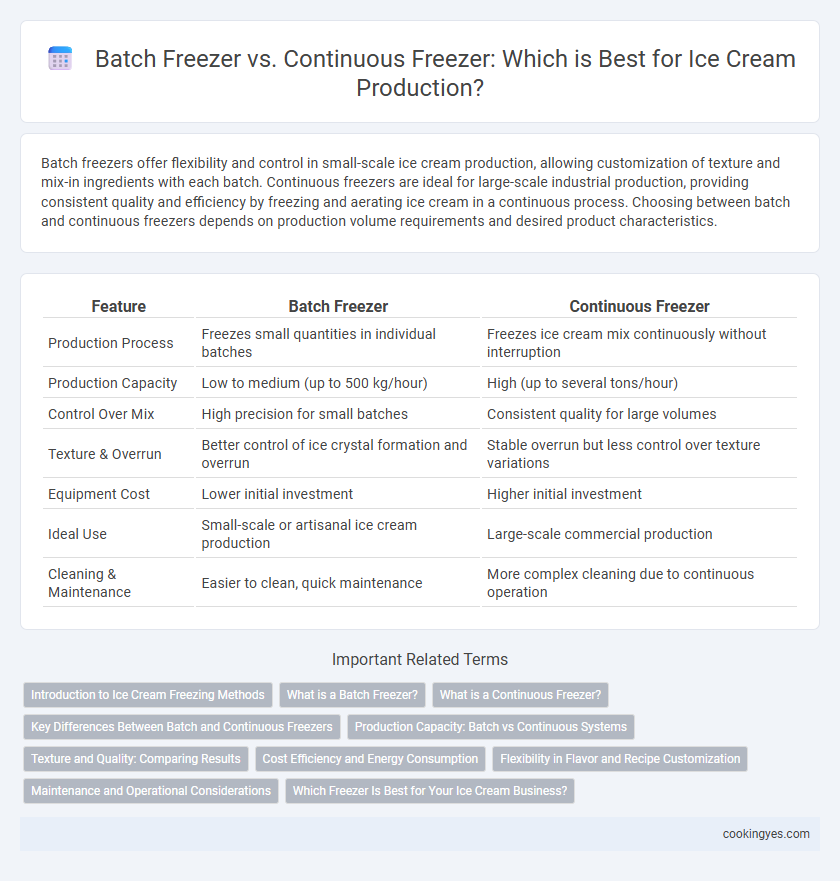

Batch freezers offer flexibility and control in small-scale ice cream production, allowing customization of texture and mix-in ingredients with each batch. Continuous freezers are ideal for large-scale industrial production, providing consistent quality and efficiency by freezing and aerating ice cream in a continuous process. Choosing between batch and continuous freezers depends on production volume requirements and desired product characteristics.

Table of Comparison

| Feature | Batch Freezer | Continuous Freezer |

|---|---|---|

| Production Process | Freezes small quantities in individual batches | Freezes ice cream mix continuously without interruption |

| Production Capacity | Low to medium (up to 500 kg/hour) | High (up to several tons/hour) |

| Control Over Mix | High precision for small batches | Consistent quality for large volumes |

| Texture & Overrun | Better control of ice crystal formation and overrun | Stable overrun but less control over texture variations |

| Equipment Cost | Lower initial investment | Higher initial investment |

| Ideal Use | Small-scale or artisanal ice cream production | Large-scale commercial production |

| Cleaning & Maintenance | Easier to clean, quick maintenance | More complex cleaning due to continuous operation |

Introduction to Ice Cream Freezing Methods

Batch freezers produce ice cream by freezing small quantities in fixed cycles, ensuring greater control over texture and mix composition, ideal for artisanal or small-scale production. Continuous freezers rapidly freeze large volumes of ice cream in an ongoing process, maximizing efficiency and throughput for industrial-scale manufacturing. The choice between batch and continuous freezing methods significantly impacts ice crystal size, overrun, and overall product consistency in ice cream production.

What is a Batch Freezer?

A batch freezer is a machine used in ice cream production that freezes a specific quantity of mix in one cycle, allowing precise control over the texture and overrun of the ice cream. This equipment is ideal for small to medium-scale production, producing rich, creamy ice cream with customizable consistency in each batch. Batch freezers operate by simultaneously freezing and churning the mix, ensuring uniform air incorporation and smooth texture throughout the final product.

What is a Continuous Freezer?

A continuous freezer is a specialized machine used in ice cream production that rapidly freezes and homogenizes the mix while incorporating air to achieve the desired texture and overrun. Unlike batch freezers, continuous freezers operate non-stop, allowing high-volume, consistent output ideal for large-scale commercial manufacturing. This technology ensures efficient production with precise control over ice crystal size, creaminess, and overall quality of the ice cream.

Key Differences Between Batch and Continuous Freezers

Batch freezers produce ice cream in discrete volumes, allowing precise control over texture and flavor customization, ideal for small-scale or artisanal production. Continuous freezers operate nonstop, efficiently freezing large quantities with consistent overrun and air incorporation, suited for mass production. Key differences include production capacity, process control, and scalability, affecting texture, consistency, and cost efficiency in ice cream manufacturing.

Production Capacity: Batch vs Continuous Systems

Batch freezers produce ice cream in smaller, controlled quantities ideal for artisanal or small-scale production, typically ranging from a few liters to several hundred liters per batch. Continuous freezers operate with higher production capacity, processing large volumes of ice cream mix continuously, often exceeding several thousand liters per hour, making them suitable for industrial-scale manufacturing. The choice between batch and continuous freezers significantly impacts production efficiency, scalability, and product consistency in ice cream production.

Texture and Quality: Comparing Results

Batch freezers produce ice cream with a creamier texture and richer flavor due to slower freezing and higher overrun control, resulting in larger ice crystals that enhance mouthfeel. Continuous freezers achieve greater consistency and smoother textures by rapidly freezing the mix with precise temperature control, minimizing ice crystal size and improving shelf stability. Quality-wise, batch freezers excel in artisanal, small-batch production, while continuous freezers are ideal for large-scale manufacturing with uniform texture and flavor.

Cost Efficiency and Energy Consumption

Batch freezers offer lower initial capital costs and greater flexibility for small to medium ice cream production volumes, making them cost-efficient for artisanal or seasonal operations. Continuous freezers provide superior energy efficiency and higher throughput by maintaining consistent freezing conditions, which reduces operational costs in large-scale manufacturing. Selecting the appropriate freezer type depends on production scale, with continuous freezers optimized for energy savings in mass production.

Flexibility in Flavor and Recipe Customization

Batch freezers offer superior flexibility for ice cream production by allowing easy adjustments in flavor and recipe customization with each batch, ideal for small to medium-scale operations or specialty flavors. Continuous freezers prioritize high-volume output but limit the ability to modify flavors or ingredients on the fly due to their continuous processing nature. Producers seeking frequent flavor innovation and personalized recipes benefit significantly from the batch freezer's adaptable production process.

Maintenance and Operational Considerations

Batch freezers require frequent cleaning and maintenance due to intermittent production cycles, increasing downtime and labor costs. Continuous freezers offer greater operational efficiency with lower maintenance needs, as they run non-stop and have fewer mechanical parts subject to wear. Selecting between the two depends on production volume and maintenance capacity, where continuous freezers suit large-scale manufacturing, and batch freezers fit artisanal or small-batch operations.

Which Freezer Is Best for Your Ice Cream Business?

Batch freezers offer greater control over texture and flavor customization, ideal for artisanal ice cream production with smaller batch sizes. Continuous freezers provide higher efficiency and consistency for large-scale ice cream businesses, producing uniform product at a faster rate. Choosing the best freezer depends on production volume, product variety, and desired quality control for the ice cream business.

Batch freezer vs continuous freezer for ice cream production Infographic

cookingyes.com

cookingyes.com