Hand-churned ice cream offers a denser texture and richer flavor profile due to slower mixing, which incorporates less air compared to machine-churned methods. Machine-churned ice cream is typically lighter and creamier as the rapid mixing process introduces more air, resulting in a smoother consistency. Choosing between the two methods affects the final mouthfeel and intensity of the ice cream's taste.

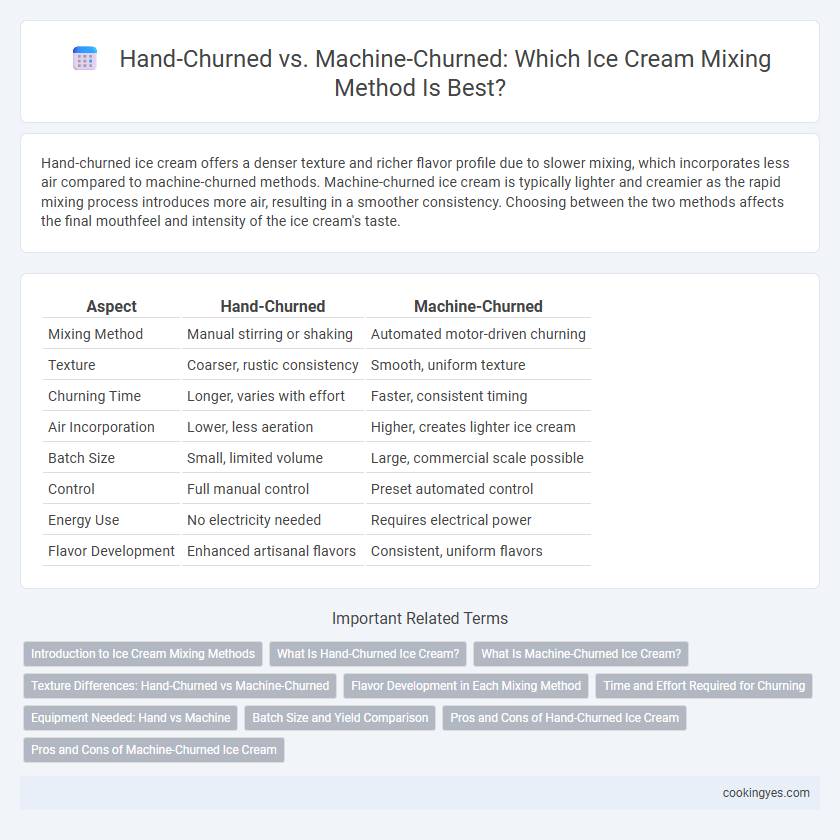

Table of Comparison

| Aspect | Hand-Churned | Machine-Churned |

|---|---|---|

| Mixing Method | Manual stirring or shaking | Automated motor-driven churning |

| Texture | Coarser, rustic consistency | Smooth, uniform texture |

| Churning Time | Longer, varies with effort | Faster, consistent timing |

| Air Incorporation | Lower, less aeration | Higher, creates lighter ice cream |

| Batch Size | Small, limited volume | Large, commercial scale possible |

| Control | Full manual control | Preset automated control |

| Energy Use | No electricity needed | Requires electrical power |

| Flavor Development | Enhanced artisanal flavors | Consistent, uniform flavors |

Introduction to Ice Cream Mixing Methods

Hand-churned ice cream involves manually stirring the mixture, creating a dense texture by incorporating smaller air bubbles through slow, consistent motion. Machine-churned ice cream uses electric mixers to rapidly blend ingredients, producing a smoother texture with increased air incorporation known as overrun. Understanding these mixing methods is crucial for selecting ice cream based on texture preferences and production efficiency.

What Is Hand-Churned Ice Cream?

Hand-churned ice cream is crafted by manually rotating a dasher inside a chilled container, allowing natural incorporation of air and gradual freezing. This traditional mixing method results in a denser texture with larger ice crystals compared to machine-churned ice cream. The slow, manual process enhances flavor complexity and creates a rustic, artisanal quality prized by ice cream connoisseurs.

What Is Machine-Churned Ice Cream?

Machine-churned ice cream is produced using automated equipment that rapidly stirs and freezes the mixture to create a smooth, consistent texture while incorporating less air than traditional hand-churning methods. This process enables precise temperature control and uniform ingredient blending, resulting in a creamier and denser final product. Commercial makers favor machine-churned ice cream for its efficiency and ability to produce large batches with consistent quality.

Texture Differences: Hand-Churned vs Machine-Churned

Hand-churned ice cream typically has a denser, creamier texture due to slower mixing that incorporates less air, resulting in a richer mouthfeel. Machine-churned ice cream, by contrast, introduces more air through rapid agitation, producing a lighter, smoother consistency with increased volume. The difference in overrun percentage--hand-churned often under 20% versus machine-churned up to 100%--significantly impacts the final texture and density of the ice cream.

Flavor Development in Each Mixing Method

Hand-churned ice cream develops a richer and more complex flavor profile due to slower freezing, which allows ice crystals to grow larger and enhances ingredient infusion. Machine-churned ice cream freezes rapidly with consistent agitation, resulting in a smoother texture but slightly less pronounced flavor depth. The slower churning process in hand methods intensifies the taste by allowing natural flavors to meld over time.

Time and Effort Required for Churning

Hand-churned ice cream demands significant manual effort and longer churning time, often ranging from 20 to 40 minutes to achieve a creamy texture. Machine-churned ice cream reduces physical labor by automating the mixing process, typically completing churning within 20 to 30 minutes. The efficiency of machine churning allows for consistent results with less time and energy invested, making it suitable for larger batches and frequent production.

Equipment Needed: Hand vs Machine

Hand-churned ice cream requires a simple, manual churn typically consisting of a wooden or plastic container with a plunger or crank to mix the ingredients, relying on physical effort to achieve the creamy texture. Machine-churned ice cream uses electric ice cream makers equipped with cooling systems and motorized paddles that consistently mix and freeze the base, ensuring uniform texture and faster production times. The choice of equipment directly impacts the consistency, texture, and overall efficiency of the ice cream-making process.

Batch Size and Yield Comparison

Hand-churned ice cream typically produces small batch sizes, often ranging from one to three quarts, resulting in limited yield per session but enhanced control over texture and mix consistency. Machine-churned methods accommodate larger batch sizes, commonly between five to fifty quarts, significantly increasing yield and efficiency for commercial production. The key difference lies in scalability, with hand-churned batches offering artisanal quality at lower volume, while machine-churned batches maximize output with consistent texture suitable for mass distribution.

Pros and Cons of Hand-Churned Ice Cream

Hand-churned ice cream offers a richer, creamier texture due to slower mixing, which allows larger ice crystals to melt, enhancing the overall mouthfeel. Its traditional process gives artisanal qualities and a more authentic flavor but requires significant time and physical effort compared to machine-churned methods. However, hand-churned ice cream often lacks the consistency and uniformity achieved by machines, which can impact large-scale production efficiency and texture perfection.

Pros and Cons of Machine-Churned Ice Cream

Machine-churned ice cream offers consistent texture and faster production, making it ideal for large-scale operations and commercial use. The mechanical process can incorporate air uniformly, resulting in a smoother and creamier product, yet it may lack the artisanal quality and subtle flavor variations found in hand-churned ice cream. However, machine-churning can sometimes lead to over-processing, causing a less natural taste and a denser texture compared to traditional methods.

Hand-Churned vs Machine-Churned for Mixing Method Infographic

cookingyes.com

cookingyes.com