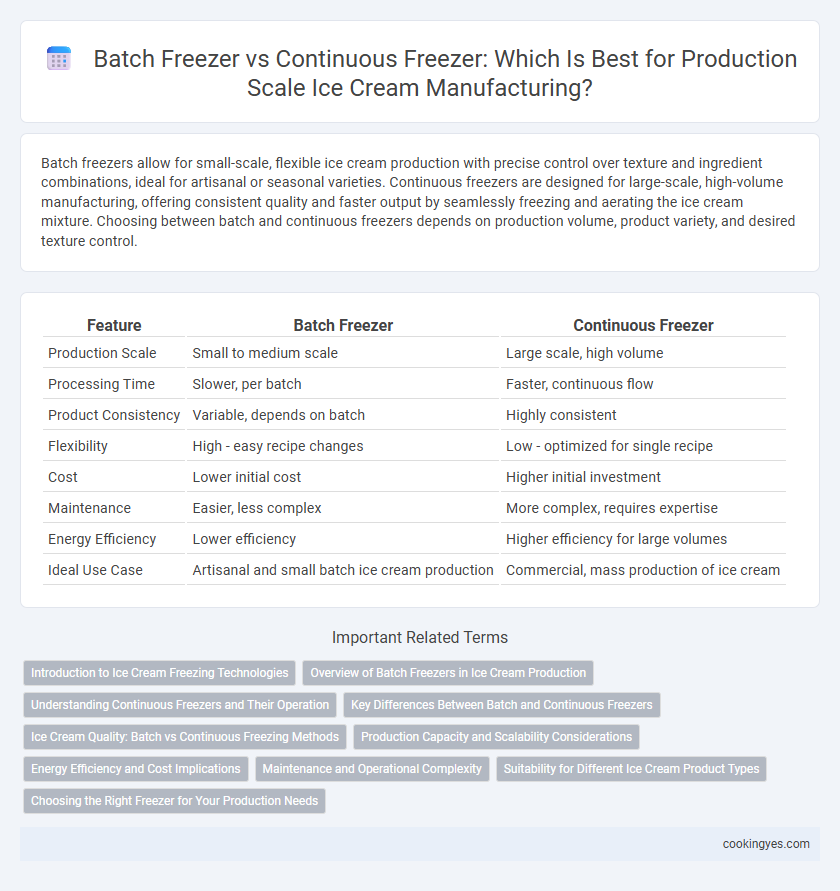

Batch freezers allow for small-scale, flexible ice cream production with precise control over texture and ingredient combinations, ideal for artisanal or seasonal varieties. Continuous freezers are designed for large-scale, high-volume manufacturing, offering consistent quality and faster output by seamlessly freezing and aerating the ice cream mixture. Choosing between batch and continuous freezers depends on production volume, product variety, and desired texture control.

Table of Comparison

| Feature | Batch Freezer | Continuous Freezer |

|---|---|---|

| Production Scale | Small to medium scale | Large scale, high volume |

| Processing Time | Slower, per batch | Faster, continuous flow |

| Product Consistency | Variable, depends on batch | Highly consistent |

| Flexibility | High - easy recipe changes | Low - optimized for single recipe |

| Cost | Lower initial cost | Higher initial investment |

| Maintenance | Easier, less complex | More complex, requires expertise |

| Energy Efficiency | Lower efficiency | Higher efficiency for large volumes |

| Ideal Use Case | Artisanal and small batch ice cream production | Commercial, mass production of ice cream |

Introduction to Ice Cream Freezing Technologies

Batch freezers process small quantities of ice cream, allowing precise control over texture and air incorporation, making them ideal for artisanal and small-scale production. Continuous freezers operate on larger volumes, delivering consistent ice cream quality with higher throughput suitable for industrial-scale manufacturing. Advancements in freezing technology enhance product uniformity, efficiency, and shelf life across both methods.

Overview of Batch Freezers in Ice Cream Production

Batch freezers in ice cream production offer precise control over texture and overrun by freezing small quantities of mix in discrete cycles, ideal for artisanal and small-scale manufacturing. These machines allow customization of ingredients and mix consistency, enhancing the quality and creaminess of the final product. Compared to continuous freezers, batch freezers provide flexibility in flavor experimentation and recipe adjustments without significant downtime.

Understanding Continuous Freezers and Their Operation

Continuous freezers operate by continuously freezing and aerating ice cream mix as it flows through the machine, allowing for high-volume production with consistent texture and overrun control. These freezers maintain precise temperature and agitation settings, ensuring uniform crystal size and smoothness in large batches. Compared to batch freezers, continuous freezers are optimized for large-scale industrial production, enabling efficient processing and reduced labor costs.

Key Differences Between Batch and Continuous Freezers

Batch freezers produce ice cream in individual, controlled batches, allowing precise customization of texture and flavor while maintaining high-quality standards. Continuous freezers operate efficiently for mass production by steadily freezing and aerating the ice cream mix, resulting in higher throughput and consistent product uniformity. Key differences include production scale, process control, and flexibility, where batch freezers offer versatility and small-scale customization, whereas continuous freezers excel in large-scale, consistent output.

Ice Cream Quality: Batch vs Continuous Freezing Methods

Batch freezers produce ice cream with a creamier texture and more controlled overrun due to slower freezing and manual ingredient incorporation, enhancing flavor retention and smoothness. Continuous freezers enable higher production capacity and consistent texture by rapidly freezing and aerating the mix, but can result in a less creamy product with lower overrun. Ice cream quality varies as batch freezing emphasizes artisanal texture and richness, while continuous freezing prioritizes efficiency and uniformity in large-scale production.

Production Capacity and Scalability Considerations

Batch freezers offer flexible production capacity ideal for artisanal or small-scale ice cream production, allowing for easy recipe adjustments and diverse product lines. Continuous freezers excel in high-volume manufacturing environments by providing consistent, large-scale output with enhanced scalability through automation and integration with upstream and downstream processes. Selecting between batch and continuous freezers depends on desired production scale, with continuous systems supporting rapid expansion and batch freezers favoring product variety and smaller runs.

Energy Efficiency and Cost Implications

Batch freezers consume less energy per cycle by freezing small quantities of ice cream, making them ideal for artisanal or low-volume production with lower upfront investment costs. Continuous freezers optimize energy efficiency through constant operation and better thermal regulation, significantly reducing energy consumption per unit in large-scale production but involve higher capital expenditure and maintenance costs. Choosing between batch and continuous freezers depends on balancing energy efficiency priorities against production scale and budget constraints.

Maintenance and Operational Complexity

Batch freezers require more frequent maintenance due to intermittent operation and complex cleaning processes, which can lead to longer downtime. Continuous freezers offer streamlined maintenance with fewer stops, benefiting from automated cleaning systems and simpler operational protocols that enhance production efficiency. Operational complexity is higher in batch freezers since operators must manually manage each batch, whereas continuous freezers provide consistent output with less manual intervention, reducing labor costs and potential errors.

Suitability for Different Ice Cream Product Types

Batch freezers excel in producing small to medium volumes of artisanal or premium ice cream varieties with distinct textures and flavors, allowing precise control over overrun and ingredient incorporation. Continuous freezers are ideal for large-scale production of uniform, mass-market ice cream products, offering high efficiency and consistent output suitable for vanilla, chocolate, and other standard flavors. Each freezer type aligns with different product goals: batch freezers for specialty, innovative flavors requiring flexibility, and continuous freezers for high-volume, consistent products.

Choosing the Right Freezer for Your Production Needs

Batch freezers offer precise control over texture and flavor, making them ideal for small to medium-scale ice cream production where variety and quality are prioritized. Continuous freezers provide high-volume output with consistent quality, suitable for large-scale operations requiring efficiency and uniformity in production. Selecting the right freezer depends on production volume, desired product characteristics, and operational flexibility to optimize costs and meet market demands.

Batch Freezer vs Continuous Freezer for Production Scale Infographic

cookingyes.com

cookingyes.com