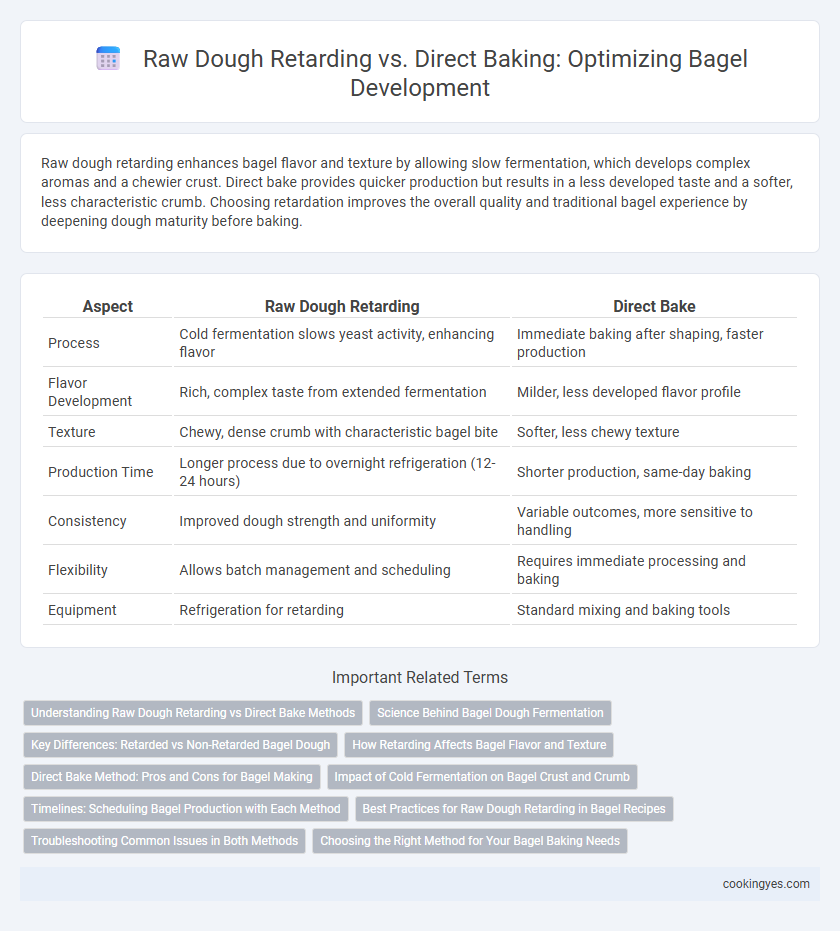

Raw dough retarding enhances bagel flavor and texture by allowing slow fermentation, which develops complex aromas and a chewier crust. Direct bake provides quicker production but results in a less developed taste and a softer, less characteristic crumb. Choosing retardation improves the overall quality and traditional bagel experience by deepening dough maturity before baking.

Table of Comparison

| Aspect | Raw Dough Retarding | Direct Bake |

|---|---|---|

| Process | Cold fermentation slows yeast activity, enhancing flavor | Immediate baking after shaping, faster production |

| Flavor Development | Rich, complex taste from extended fermentation | Milder, less developed flavor profile |

| Texture | Chewy, dense crumb with characteristic bagel bite | Softer, less chewy texture |

| Production Time | Longer process due to overnight refrigeration (12-24 hours) | Shorter production, same-day baking |

| Consistency | Improved dough strength and uniformity | Variable outcomes, more sensitive to handling |

| Flexibility | Allows batch management and scheduling | Requires immediate processing and baking |

| Equipment | Refrigeration for retarding | Standard mixing and baking tools |

Understanding Raw Dough Retarding vs Direct Bake Methods

Raw dough retarding involves refrigerating bagel dough for extended fermentation, enhancing flavor complexity and texture by slowing yeast activity. Direct bake skips the refrigeration step, resulting in a faster turnaround but often less developed taste and denser crumb structure. Choosing between these methods affects bagel chewiness, crust thickness, and overall quality, with retarding favored for artisanal-style bagels.

Science Behind Bagel Dough Fermentation

Raw dough retarding involves slowing fermentation by storing bagel dough at low temperatures, enhancing enzymatic activity and producing complex flavor compounds through extended yeast and bacterial metabolism. In contrast, direct bake methods utilize a shorter fermentation time, resulting in less acidic dough with simpler flavor profiles and firmer texture. The science behind bagel dough fermentation highlights how temperature and time control yeast activity and organic acid formation, directly impacting crust structure and crumb chewiness.

Key Differences: Retarded vs Non-Retarded Bagel Dough

Retarded bagel dough undergoes cold fermentation, slowing yeast activity to enhance flavor complexity and improve dough strength, resulting in a chewier crust and more developed taste profile. Non-retarded, or direct bake dough, is shaped and baked immediately after mixing, producing a fresher, lighter bagel with a less pronounced flavor but quicker turnaround time. The choice between retarded and non-retarded methods impacts texture, fermentation chemistry, and shelf life, influencing the overall quality and consumer appeal of the final bagel product.

How Retarding Affects Bagel Flavor and Texture

Retarding raw dough in bagel production enhances flavor by allowing prolonged fermentation, which increases the development of organic acids and complex sugars, resulting in a richer, tangier taste. This process also improves texture by promoting a chewier crumb and a thicker, glossier crust due to optimal gluten strengthening and moisture retention. Direct bake methods yield faster results but often produce bagels with a milder flavor and a less resilient texture.

Direct Bake Method: Pros and Cons for Bagel Making

The Direct Bake Method in bagel making involves baking the dough immediately after shaping, which enhances production speed and yields a softer crust preferred in certain styles. This approach reduces fermentation time, minimizing sourness but may compromise the complex flavor and chewiness developed through longer retarding periods. Bakers must balance the trade-off between efficiency and the traditional dense texture that defines classic bagels when choosing the direct bake technique.

Impact of Cold Fermentation on Bagel Crust and Crumb

Cold fermentation during raw dough retarding enhances bagel development by allowing the yeast to ferment slowly, resulting in a more complex flavor profile and improved crust texture. This process promotes a chewy crumb and a glossy, well-formed crust due to controlled enzymatic activity and moisture retention. Direct bake methods often yield less flavor depth and a softer crust, lacking the characteristic chew and slight crispness achieved through cold fermentation.

Timelines: Scheduling Bagel Production with Each Method

Raw dough retarding extends fermentation by chilling the dough for 12 to 24 hours, enhancing flavor complexity and allowing flexible scheduling in bagel production. Direct bake involves immediate boiling and baking within 2 to 4 hours, enabling rapid turnaround but yielding less developed taste profiles. Balancing these timelines impacts production efficiency, with retarding suited for batch planning and direct bake ideal for high-demand, quick-service environments.

Best Practices for Raw Dough Retarding in Bagel Recipes

Raw dough retarding enhances bagel flavor and texture by slowing fermentation at cold temperatures, allowing complex sugars and acids to develop. Best practices include refrigerating the shaped dough for 12 to 24 hours, maintaining consistent temperatures between 38degF and 45degF, and avoiding over-proofing to preserve the dense crumb and chewy crust characteristic of traditional bagels. Proper retarding improves gluten structure and fermentation control, resulting in superior bagel quality compared to direct baking methods.

Troubleshooting Common Issues in Both Methods

Raw dough retarding enhances flavor and chewiness in bagels by slowing yeast activity and allowing enzymes to develop complex sugars, but can cause over-proofing or dense texture if refrigeration time exceeds 24 hours. Direct bake methods require precise timing to avoid under-proofed dough, which leads to tough crusts and uneven crumb structure. Troubleshooting involves monitoring fermentation temperature and duration to achieve balance between oven spring and texture consistency in both retarded and direct bake processes.

Choosing the Right Method for Your Bagel Baking Needs

Raw dough retarding enhances bagel flavor and texture by slowing fermentation, allowing complex acids and yeast activity to develop, which creates a chewier crust and a more pronounced tang. Direct bake, on the other hand, is faster and yields softer bagels with less fermentation flavor, suitable for high-volume or quick-turnaround baking. Selecting the right method depends on desired bagel characteristics, production time constraints, and bakery equipment capabilities.

Raw dough retarding vs direct bake for bagel development Infographic

cookingyes.com

cookingyes.com