Hand-rolled bagels offer a denser, chewier texture and a more artisanal appearance due to the individual attention each dough ball receives. Machine-made bagels provide consistent size and shape, optimizing production speed and uniformity for commercial purposes. Choosing between hand-rolled and machine-made depends on whether quality and traditional craftsmanship or efficiency and consistency are prioritized.

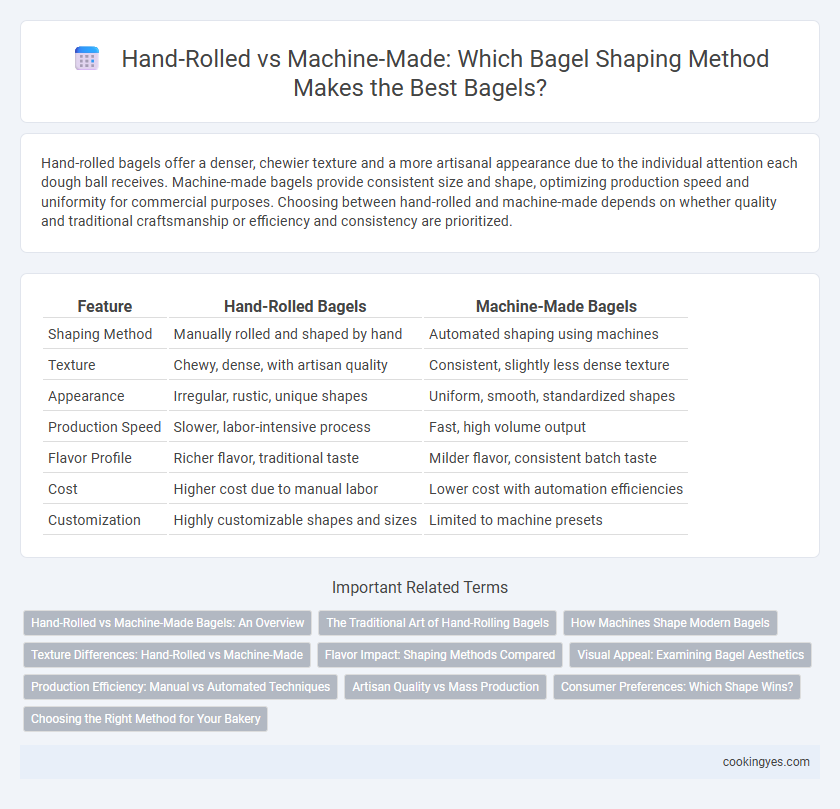

Table of Comparison

| Feature | Hand-Rolled Bagels | Machine-Made Bagels |

|---|---|---|

| Shaping Method | Manually rolled and shaped by hand | Automated shaping using machines |

| Texture | Chewy, dense, with artisan quality | Consistent, slightly less dense texture |

| Appearance | Irregular, rustic, unique shapes | Uniform, smooth, standardized shapes |

| Production Speed | Slower, labor-intensive process | Fast, high volume output |

| Flavor Profile | Richer flavor, traditional taste | Milder flavor, consistent batch taste |

| Cost | Higher cost due to manual labor | Lower cost with automation efficiencies |

| Customization | Highly customizable shapes and sizes | Limited to machine presets |

Hand-Rolled vs Machine-Made Bagels: An Overview

Hand-rolled bagels maintain a traditional texture with a denser, chewier crumb due to individualized dough shaping, which preserves irregularities that enhance flavor absorption during boiling and baking. Machine-made bagels offer uniform size and faster production but often lack the artisanal depth and complex crust development distinctive to hand-rolled methods. The choice between hand-rolled and machine-made directly impacts bagel authenticity, texture quality, and consumer perception in competitive bakery markets.

The Traditional Art of Hand-Rolling Bagels

Hand-rolling bagels preserves the traditional texture and chewy crust that defines authentic New York-style bagels, achieved through skilled, rhythmic shaping. This artisanal technique allows precise control over dough density and creates the characteristic cinnamon roll-like spiral unmatched by machine-made counterparts. Maintaining the age-old hand-rolling method ensures artisanal quality and authenticity cherished by bagel connoisseurs worldwide.

How Machines Shape Modern Bagels

Machines shape modern bagels by using precise, automated rollers and conveyors that ensure consistent size and uniform density throughout the dough ring. This mechanized process increases production speed and reduces human error, resulting in evenly shaped bagels with a uniform crust and texture. Industrial bagel-making machines can produce hundreds of bagels per hour, maintaining quality control far beyond traditional hand-rolled methods.

Texture Differences: Hand-Rolled vs Machine-Made

Hand-rolled bagels exhibit a denser, chewier texture due to the uneven pressure and artisanal shaping, which traps air differently within the dough. Machine-made bagels typically have a more uniform, lighter crumb and smoother surface because of consistent shaping and compression. Texture variations influence the overall eating experience, with hand-rolled bagels often favored for their authentically rustic bite.

Flavor Impact: Shaping Methods Compared

Hand-rolled bagels develop a denser, chewier texture and a more complex flavor profile due to the careful molding that preserves gas bubbles essential for fermentation. Machine-made bagels tend to be more uniform in size and shape but may sacrifice subtle flavor nuances and the characteristic chewiness favored by traditionalists. The shaping method directly influences gluten network formation and crust development, making hand-rolling superior for authentic taste and texture.

Visual Appeal: Examining Bagel Aesthetics

Hand-rolled bagels feature a unique, rustic texture with uneven, artisanal surface patterns that highlight their handcrafted origin, enhancing visual appeal. Machine-made bagels typically present a uniform shape and smooth exterior, delivering consistent symmetry ideal for mass production. The distinct visual characteristics influence consumer perception, with hand-rolled bagels often associated with authenticity and traditional quality.

Production Efficiency: Manual vs Automated Techniques

Hand-rolled bagel shaping emphasizes craftsmanship and traditional texture but requires significantly more time and labor, limiting production capacity. Machine-made bagels streamline the shaping process, enabling higher output with consistent size and shape, enhancing overall production efficiency. Automated techniques reduce human error and accelerate batch processing, making them ideal for large-scale bagel manufacturing.

Artisan Quality vs Mass Production

Hand-rolled bagels showcase artisan quality through precise texture and unique character, achieved by skilled bakers manipulating dough to maintain ideal gluten structure. Machine-made bagels emphasize mass production efficiency, often resulting in uniform shapes but sacrificing the nuanced chew and complex flavor of traditionally hand-rolled bagels. The distinct tactile and visual appeal of hand-rolled bagels reflects craftsmanship, while machine-made varieties prioritize speed and volume.

Consumer Preferences: Which Shape Wins?

Hand-rolled bagels are favored by consumers who value authentic texture and artisanal quality, often characterized by a denser, chewier crumb and uneven, rustic shapes. Machine-made bagels appeal to buyers seeking consistency, uniform sizing, and faster production, commonly found in commercial bakeries and supermarkets. Consumer preference leans toward hand-rolled bagels in specialty markets where craftsmanship is prized, while machine-made bagels dominate mass-market channels due to convenience and cost efficiency.

Choosing the Right Method for Your Bakery

Hand-rolled bagels offer artisanal texture and irregular shapes that appeal to consumers seeking authenticity, while machine-made bagels ensure uniform size and shape for high-volume production efficiency. Bakeries prioritizing quality and traditional craftsmanship should opt for hand-rolling to emphasize uniqueness and flavor development, whereas those targeting consistency and faster output benefit from machine shaping. Selecting the right method depends on balancing customer expectations, production scale, and desired product characteristics within your bakery operations.

Hand-rolled vs machine-made for bagel shaping Infographic

cookingyes.com

cookingyes.com