Hot press sandwich techniques use heat and pressure to bond layers quickly, resulting in a denser and smoother surface ideal for detailed finishes. Cold stack methods rely on adhesive and mechanical stacking without heat, preserving material integrity and reducing warping or deformation. Choosing between hot press and cold stack depends on the desired texture, durability, and production speed for the sandwich application.

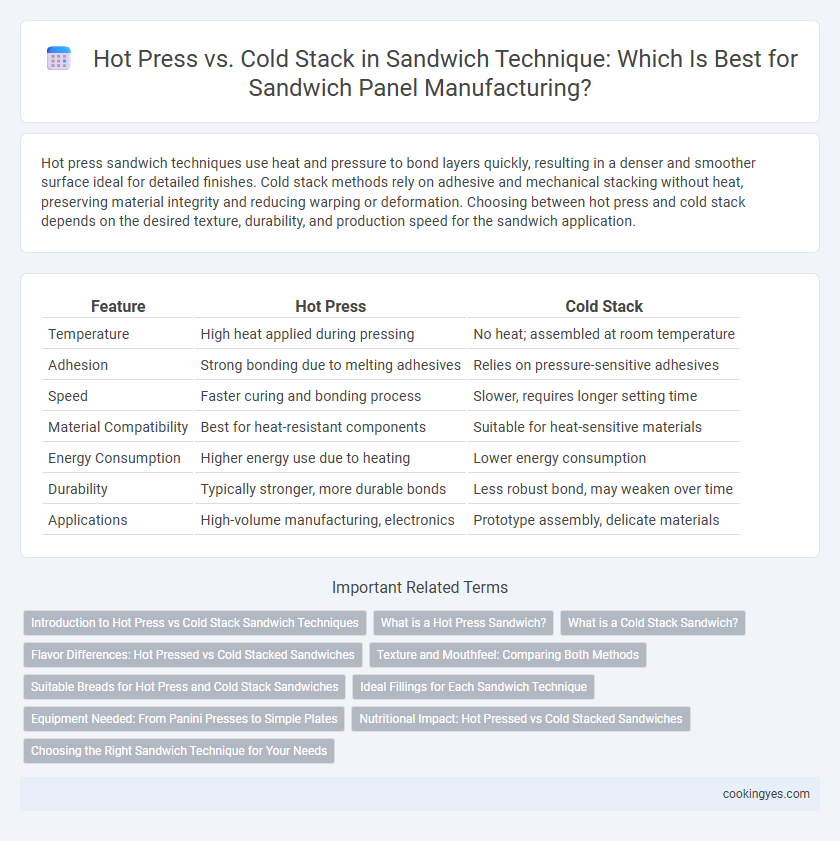

Table of Comparison

| Feature | Hot Press | Cold Stack |

|---|---|---|

| Temperature | High heat applied during pressing | No heat; assembled at room temperature |

| Adhesion | Strong bonding due to melting adhesives | Relies on pressure-sensitive adhesives |

| Speed | Faster curing and bonding process | Slower, requires longer setting time |

| Material Compatibility | Best for heat-resistant components | Suitable for heat-sensitive materials |

| Energy Consumption | Higher energy use due to heating | Lower energy consumption |

| Durability | Typically stronger, more durable bonds | Less robust bond, may weaken over time |

| Applications | High-volume manufacturing, electronics | Prototype assembly, delicate materials |

Introduction to Hot Press vs Cold Stack Sandwich Techniques

Hot press and cold stack are two popular sandwich preparation techniques that significantly impact texture and flavor. Hot press sandwiches are grilled or toasted, melting cheese and toasting bread for a warm, crispy experience, while cold stack sandwiches use fresh, cold ingredients layered without heat, preserving the natural flavors and crispness. Choosing between hot press and cold stack depends on desired temperature, texture, and ingredient combination preferences.

What is a Hot Press Sandwich?

A hot press sandwich is prepared by heating the sandwich ingredients between two heated plates, which crisps the bread and melts the fillings for enhanced flavor and texture. This technique uses a sandwich press or panini maker to apply even heat and pressure, resulting in a warm, toasted exterior and gooey interior. The hot press method is ideal for sandwiches with cheese, meats, and vegetables, as it intensifies taste through heat-induced caramelization and melding of flavors.

What is a Cold Stack Sandwich?

A cold stack sandwich consists of multiple layers of cold ingredients like deli meats, cheeses, and fresh vegetables stacked without toasting or heating. This technique preserves the natural flavors and textures, offering a crisp and refreshing taste. Cold stack sandwiches are ideal for maintaining ingredient freshness and are often preferred in deli-style or picnic meals.

Flavor Differences: Hot Pressed vs Cold Stacked Sandwiches

Hot pressed sandwiches develop a rich, toasted flavor and melted texture as heat enhances the Maillard reaction, intensifying savory and slightly caramelized notes. Cold stacked sandwiches preserve the original freshness and crispness of ingredients, highlighting natural flavors like the sweetness of fresh vegetables and sharpness of cold cuts. The temperature difference directly influences flavor perception, with hot pressing amplifying warmth and umami, while cold stacking offers a clean, vibrant taste profile.

Texture and Mouthfeel: Comparing Both Methods

Hot press sandwiches create a crispy, toasted exterior with melted fillings, resulting in a warm, crunchy texture and a gooey mouthfeel that contrasts textures in each bite. Cold stack sandwiches maintain the original softness and freshness of bread and fillings, offering a lighter, more airy texture with distinct layers that deliver a clean, crisp mouthfeel. The choice between hot pressing and cold stacking directly influences the sensory experience, with hot pressing enhancing warmth and crunch, while cold stacking preserves freshness and layered textures.

Suitable Breads for Hot Press and Cold Stack Sandwiches

Hot press sandwiches are ideal for breads like ciabatta, focaccia, and sourdough, which can withstand high heat and develop a crispy crust while retaining a soft interior. Cold stack sandwiches suit softer breads such as white sandwich bread, whole wheat, and brioche, preserving their tender texture and moisture without exposure to heat. Each technique enhances different bread qualities, optimizing texture and flavor depending on whether the sandwich is served warm or cold.

Ideal Fillings for Each Sandwich Technique

Hot press sandwiches are ideal for fillings that melt or benefit from heat, such as cheese, grilled vegetables, and cooked meats like ham or chicken, allowing flavors to meld and textures to soften. Cold stack sandwiches work best with fresh, crisp ingredients like deli meats, leafy greens, tomatoes, and spreads like hummus or mayonnaise, preserving their natural crunch and freshness. Choosing fillings based on the sandwich technique enhances taste and texture, making hot presses perfect for warm, gooey combinations and cold stacks optimal for vibrant, fresh bites.

Equipment Needed: From Panini Presses to Simple Plates

Hot press sandwich techniques require specialized equipment such as panini presses or electric grills that provide even heat and pressure to achieve a crispy, toasted exterior and gooey interior. Cold stack methods rely on minimal tools, often just simple plates or parchment paper to layer ingredients without heat, preserving fresh textures and flavors. Investing in a quality panini press offers temperature control and uniform pressing, whereas cold stacking emphasizes ease and speed with little to no equipment costs.

Nutritional Impact: Hot Pressed vs Cold Stacked Sandwiches

Hot pressed sandwiches often experience nutrient loss due to high heat, which can degrade heat-sensitive vitamins like vitamin C and some B-complex vitamins. Cold stacked sandwiches better preserve these micronutrients and maintain the integrity of fresh ingredients such as leafy greens and raw vegetables, enhancing overall nutritional value. However, hot pressed sandwiches can improve digestibility and flavor through the Maillard reaction, which may aid nutrient absorption.

Choosing the Right Sandwich Technique for Your Needs

Choosing the right sandwich technique depends on your desired texture and flavor profile; hot press sandwiches offer a crispy outer layer with melted fillings, ideal for those seeking a warm, gooey bite. Cold stack sandwiches preserve fresh ingredients and distinct flavors, perfect for a light, refreshing meal. Consider the type of bread and fillings to ensure optimal taste and structural integrity for your sandwich.

Hot press vs cold stack for sandwich technique Infographic

cookingyes.com

cookingyes.com