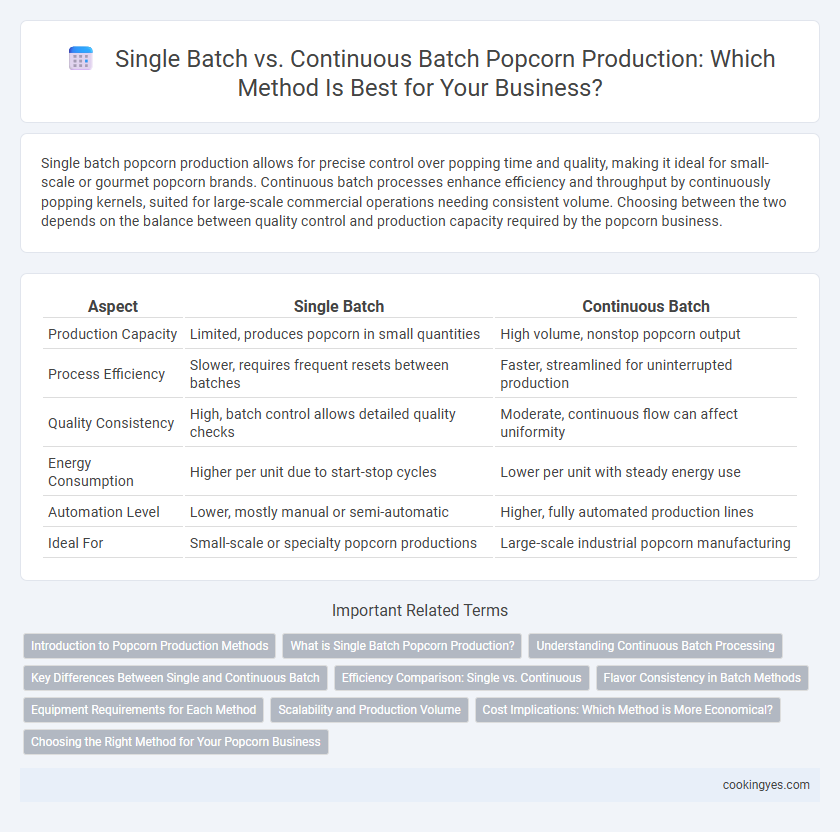

Single batch popcorn production allows for precise control over popping time and quality, making it ideal for small-scale or gourmet popcorn brands. Continuous batch processes enhance efficiency and throughput by continuously popping kernels, suited for large-scale commercial operations needing consistent volume. Choosing between the two depends on the balance between quality control and production capacity required by the popcorn business.

Table of Comparison

| Aspect | Single Batch | Continuous Batch |

|---|---|---|

| Production Capacity | Limited, produces popcorn in small quantities | High volume, nonstop popcorn output |

| Process Efficiency | Slower, requires frequent resets between batches | Faster, streamlined for uninterrupted production |

| Quality Consistency | High, batch control allows detailed quality checks | Moderate, continuous flow can affect uniformity |

| Energy Consumption | Higher per unit due to start-stop cycles | Lower per unit with steady energy use |

| Automation Level | Lower, mostly manual or semi-automatic | Higher, fully automated production lines |

| Ideal For | Small-scale or specialty popcorn productions | Large-scale industrial popcorn manufacturing |

Introduction to Popcorn Production Methods

Popcorn production utilizes single batch and continuous batch methods, each offering distinct advantages in yield and efficiency. Single batch production involves popping kernels in discrete, controlled quantities, ensuring consistent quality and flavor for smaller operations. Continuous batch production enables higher throughput by constantly feeding kernels into the popping system, ideal for large-scale manufacturing and meeting high consumer demand.

What is Single Batch Popcorn Production?

Single batch popcorn production involves popping a predetermined quantity of kernels in one cycle, ensuring consistent quality and flavor per batch. This method allows precise control over popping time and temperature, resulting in uniform kernels and minimized waste. Single batch systems are ideal for artisanal popcorn makers prioritizing product consistency over high-volume output.

Understanding Continuous Batch Processing

Continuous batch processing in popcorn production enhances efficiency by allowing kernels to be popped in a steady stream, reducing downtime between batches. This method ensures consistent quality and uniform heat distribution, leading to higher throughput compared to single batch processing. By optimizing temperature control and kernel flow, continuous batch systems minimize product waste and improve overall operational capacity.

Key Differences Between Single and Continuous Batch

Single batch popcorn production processes a fixed quantity of kernels at once, allowing precise control over popping conditions and batch consistency, ideal for small to medium-scale operations. Continuous batch systems operate by continuously feeding kernels through a popping mechanism, enabling higher throughput and efficiency suited for large-scale industrial output. Key differences include processing volume, operational speed, and equipment complexity, with single batch methods offering flexibility and quality control while continuous systems prioritize productivity and scale.

Efficiency Comparison: Single vs. Continuous

Single batch popcorn production offers precise control over kernel popping, resulting in higher quality but lower throughput. Continuous batch systems maximize efficiency by processing large volumes with consistent output, reducing downtime and energy consumption per unit. Efficiency gains in continuous systems stem from streamlined operations and minimized manual handling, making them ideal for large-scale production.

Flavor Consistency in Batch Methods

Single batch production in popcorn manufacturing ensures precise control over popping time and temperature, leading to consistent flavor and texture in each batch. Continuous batch processes, while efficient for high-volume output, may encounter slight variations in heat exposure that can affect flavor uniformity. Maintaining flavor consistency is critical for consumer satisfaction, making single batch methods preferable when product quality is prioritized over production speed.

Equipment Requirements for Each Method

Single batch popcorn production demands equipment such as countertop poppers or kettle machines that handle limited quantities per cycle, emphasizing portability and flexibility. Continuous batch systems require larger, industrial-grade poppers with conveyor belts and automated feeders to maintain an uninterrupted flow of kernels and consistent output. Choosing between these methods hinges on factors like production volume, space availability, and the need for automation in popcorn manufacturing.

Scalability and Production Volume

Single batch popcorn production offers precise control over kernel popping and flavor consistency but is limited in scalability and lower production volumes, making it ideal for artisanal or small-scale operations. Continuous batch processes enable high scalability and significantly increased production volume by maintaining a constant flow of kernels through automated systems, suitable for large commercial popcorn manufacturers. Efficient heat distribution and real-time quality monitoring in continuous batch systems further enhance productivity and product uniformity at scale.

Cost Implications: Which Method is More Economical?

Single batch popcorn production involves cooking limited quantities at once, resulting in higher labor and energy costs per unit due to frequent equipment startups and downtime. Continuous batch systems use automated processes to produce large volumes of popcorn nonstop, significantly reducing operational costs and increasing efficiency. For large-scale operations, continuous batch production is generally more economical, while single batch may suit smaller or artisanal producers with lower output demands.

Choosing the Right Method for Your Popcorn Business

Choosing the right popcorn production method impacts product quality and operational efficiency; single batch processing offers precise control and consistent kernel popping for small to medium-scale businesses, while continuous batch systems enhance throughput and reduce labor costs suited for high-volume manufacturers. Single batch machines allow customization of flavor and topping application per batch, ideal for gourmet or specialty popcorn brands. Continuous batch production ensures steady output and scalability, meeting large retail or event demands without sacrificing uniformity.

Single batch vs Continuous batch for popcorn production Infographic

cookingyes.com

cookingyes.com