Machine-cut pierogi offer uniformity in shape and size, ensuring consistent cooking times and a polished appearance. Hand-cut pierogi provide a rustic, artisanal look with slight variations that enhance their homemade charm and texture. Choosing between machine-cut and hand-cut shapes depends on whether precision or traditional aesthetics are prioritized for the pierogi experience.

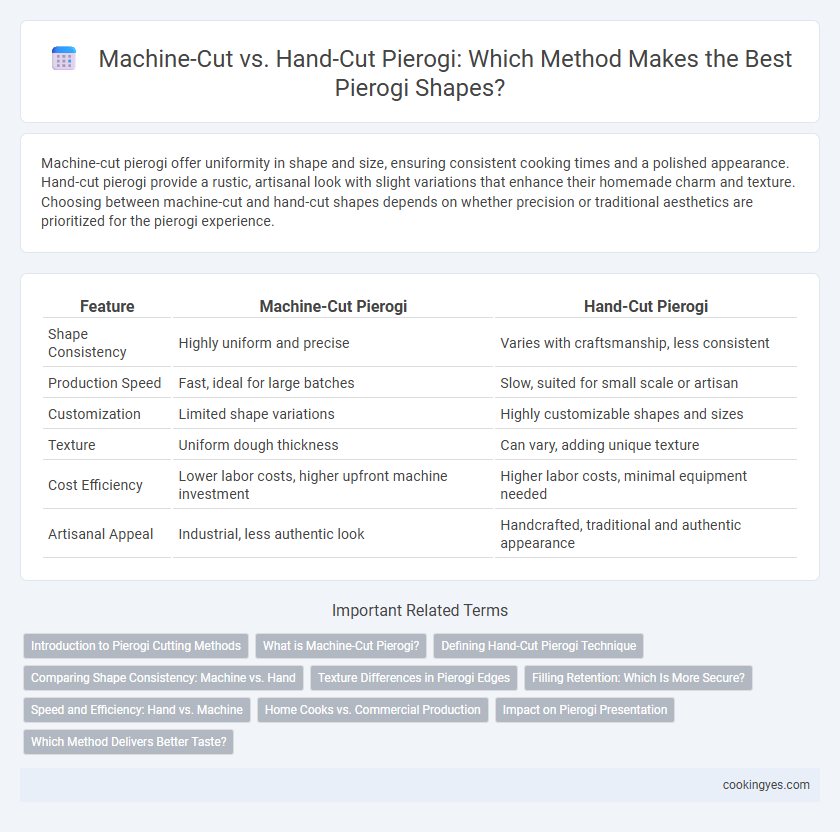

Table of Comparison

| Feature | Machine-Cut Pierogi | Hand-Cut Pierogi |

|---|---|---|

| Shape Consistency | Highly uniform and precise | Varies with craftsmanship, less consistent |

| Production Speed | Fast, ideal for large batches | Slow, suited for small scale or artisan |

| Customization | Limited shape variations | Highly customizable shapes and sizes |

| Texture | Uniform dough thickness | Can vary, adding unique texture |

| Cost Efficiency | Lower labor costs, higher upfront machine investment | Higher labor costs, minimal equipment needed |

| Artisanal Appeal | Industrial, less authentic look | Handcrafted, traditional and authentic appearance |

Introduction to Pierogi Cutting Methods

Machine-cut pierogi shapes offer precision and uniformity, ensuring consistent dough thickness and size ideal for mass production and commercial use. Hand-cut pierogi shapes, crafted using traditional techniques, provide unique, rustic edges and allow for customization in shape and size, preserving artisanal quality. Both methods impact the texture and cooking performance of pierogi, influencing the overall dining experience.

What is Machine-Cut Pierogi?

Machine-cut pierogi are produced using industrial dough sheeters and cutters that ensure uniform shapes and consistent thickness, enhancing production efficiency and product consistency. This automated process is designed to replicate traditional pierogi shapes with precision, reducing manual labor and minimizing dough waste. Machine-cut pierogi often meet large-scale demand in commercial kitchens and frozen food manufacturing while maintaining standard quality and appearance.

Defining Hand-Cut Pierogi Technique

Hand-cut pierogi involve shaping dough pieces individually with a knife or specialized tool, ensuring each piece has a unique, rustic texture and thickness that machines cannot replicate. This traditional technique allows for greater control over dough consistency and sealing, which enhances the overall flavor and mouthfeel of the pierogi. The subtle variations from hand-cutting contribute to an artisanal quality highly valued in authentic Eastern European cuisine.

Comparing Shape Consistency: Machine vs. Hand

Machine-cut pierogi consistently offer uniform shapes and sizes, ensuring even cooking and professional presentation, which is critical in commercial production. Hand-cut pierogi, while often showcasing a rustic and artisanal charm with slight variations, may result in inconsistent thickness and cooking times. The precision of machine cutting enhances efficiency and repeatability, whereas hand-cut pierogi emphasize traditional craftsmanship and uniqueness in each piece.

Texture Differences in Pierogi Edges

Machine-cut pierogi edges exhibit uniform thickness and clean, precise seals, resulting in a consistent, slightly firmer texture that holds fillings securely under cooking. Hand-cut pierogi edges often have slight irregularities and varied thickness, creating uneven textures with softer, more delicate edges that can enhance the overall bite experience. These textural differences influence the mouthfeel, with machine-cut edges providing a more structured chew, while hand-cut edges offer a traditional, tender finish.

Filling Retention: Which Is More Secure?

Machine-cut pierogi shapes offer consistent edges that enhance filling retention by creating uniform seals, reducing the risk of filling leakage during cooking. Hand-cut pierogi, while often providing a rustic appearance, may result in uneven edges that compromise the seal, leading to potential filling loss. Precise sealing techniques and dough thickness also significantly influence filling security regardless of the cutting method.

Speed and Efficiency: Hand vs. Machine

Machine-cut pierogi significantly boost speed and efficiency, producing uniform shapes at a rapid pace ideal for large-scale production. Hand-cut pierogi, while slower, offer unique shape variations and artisanal quality that machines cannot replicate. For commercial operations, machine cutting optimizes output and consistency, whereas hand-cutting favors craftsmanship and traditional appeal.

Home Cooks vs. Commercial Production

Machine-cut pierogi shapes offer consistent size and uniform thickness, which is ideal for commercial production to ensure even cooking and streamlined packaging. Hand-cut pierogi provide a rustic, artisanal look with slight variations that appeal to home cooks seeking authenticity and personal touch. The precision of machine cutting saves time and labor in large batches, whereas hand-cutting allows for creative customization in small-scale, homemade batches.

Impact on Pierogi Presentation

Machine-cut pierogi shapes provide consistent edges and uniform size, enhancing the visual appeal through precise symmetry and smooth contours. Hand-cut pierogi offer a rustic, artisanal look with slight variations in shape and thickness that create a homemade aesthetic, appealing to traditional food enthusiasts. The choice between machine and hand-cut methods significantly influences pierogi presentation, affecting both consumer perception and plating style in culinary settings.

Which Method Delivers Better Taste?

Machine-cut pierogi offer consistent thickness and uniform edges, which enhance even cooking and texture, contributing to a reliable taste experience. Hand-cut pierogi, with their irregular shapes and variable thickness, often allow for a more artisanal bite and personalized texture that can elevate flavor perception. Taste preferences vary, but many gourmets find hand-cut pierogi deliver superior flavor complexity due to the natural variation in dough and filling distribution.

Machine-cut vs Hand-cut for Pierogi Shapes Infographic

cookingyes.com

cookingyes.com