Stabilizers and emulsifiers both play crucial roles in ice cream consistency but serve different functions; stabilizers prevent ice crystal growth by binding water and maintaining texture, while emulsifiers improve fat dispersion and enhance creaminess by helping fat and water blend smoothly. Using the right balance of stabilizers and emulsifiers ensures a smooth, creamy ice cream that resists melting and maintains its desirable mouthfeel. Proper formulation with these additives is essential for achieving consistent texture and optimal product quality in ice cream manufacturing.

Table of Comparison

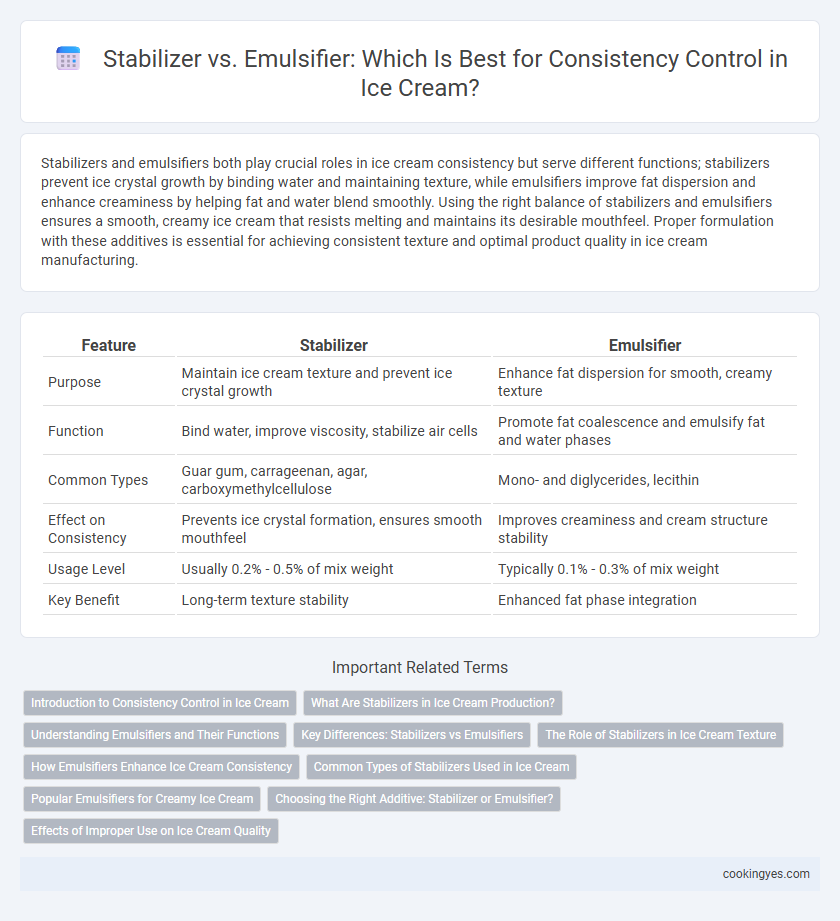

| Feature | Stabilizer | Emulsifier |

|---|---|---|

| Purpose | Maintain ice cream texture and prevent ice crystal growth | Enhance fat dispersion for smooth, creamy texture |

| Function | Bind water, improve viscosity, stabilize air cells | Promote fat coalescence and emulsify fat and water phases |

| Common Types | Guar gum, carrageenan, agar, carboxymethylcellulose | Mono- and diglycerides, lecithin |

| Effect on Consistency | Prevents ice crystal formation, ensures smooth mouthfeel | Improves creaminess and cream structure stability |

| Usage Level | Usually 0.2% - 0.5% of mix weight | Typically 0.1% - 0.3% of mix weight |

| Key Benefit | Long-term texture stability | Enhanced fat phase integration |

Introduction to Consistency Control in Ice Cream

Stabilizers and emulsifiers play crucial roles in controlling the consistency of ice cream by enhancing texture and stability. Stabilizers, such as guar gum and carrageenan, help maintain moisture and prevent ice crystal growth, ensuring a smooth, creamy mouthfeel. Emulsifiers like lecithin improve fat dispersion and air incorporation, contributing to uniformity and a stable, desirable ice cream structure.

What Are Stabilizers in Ice Cream Production?

Stabilizers in ice cream production are hydrocolloids such as guar gum, carrageenan, and xanthan gum that help maintain texture by preventing ice crystal growth and water separation. They enhance creaminess and mouthfeel by binding water and stabilizing the mixture during freezing and storage. Proper use of stabilizers ensures a smooth, consistent product with extended shelf life, differentiating them from emulsifiers that primarily improve fat dispersion.

Understanding Emulsifiers and Their Functions

Emulsifiers in ice cream stabilize the mixture by allowing fat and water to blend smoothly, preventing separation and improving texture. These agents reduce surface tension between ingredients, which enhances creaminess and consistency throughout the product. Common emulsifiers like lecithin and monoglycerides ensure a uniform structure, contributing to a stable and enjoyable ice cream experience.

Key Differences: Stabilizers vs Emulsifiers

Stabilizers and emulsifiers play distinct roles in ice cream consistency control; stabilizers like guar gum and xanthan gum primarily prevent ice crystal growth and improve texture by retaining water, while emulsifiers such as lecithin and mono- and diglycerides enhance fat dispersion and improve air incorporation. Stabilizers maintain the ice cream's smoothness and prevent meltdown, whereas emulsifiers strengthen the fat network for better creaminess and volume. Understanding these key differences helps optimize ice cream formulations for ideal texture and stability.

The Role of Stabilizers in Ice Cream Texture

Stabilizers in ice cream play a crucial role in maintaining texture by preventing ice crystal growth and enhancing creaminess through moisture retention. Common stabilizers such as guar gum, carrageenan, and xanthan gum create a gel-like network that traps water, ensuring a smooth and consistent mouthfeel. These ingredients improve the overall stability and shelf life of ice cream by reducing ice recrystallization during freeze-thaw cycles.

How Emulsifiers Enhance Ice Cream Consistency

Emulsifiers in ice cream play a crucial role in improving texture by promoting uniform fat distribution and reducing fat globule size, which creates a smoother and creamier mouthfeel. They enhance air incorporation, stabilizing air bubbles to ensure consistent volume and prevent ice crystal growth during storage. This results in an ice cream with improved stability, creaminess, and resistance to melt-off.

Common Types of Stabilizers Used in Ice Cream

Common stabilizers used in ice cream to control consistency include guar gum, carrageenan, and xanthan gum, which prevent ice crystal growth and improve texture. These polysaccharides thicken the ice cream mix, enhancing creaminess and preventing separation during freezing. Their ability to bind water and stabilize air bubbles ensures a smoother, more stable product with an extended shelf life.

Popular Emulsifiers for Creamy Ice Cream

Popular emulsifiers in creamy ice cream include lecithin, mono- and diglycerides, and polysorbates, which enhance fat dispersion and improve texture stability. Stabilizers like guar gum and carrageenan work differently by binding water to prevent ice crystal formation, but emulsifiers specifically aid in creating a smooth, creamy mouthfeel by promoting the blending of fat and water phases. The precise combination and concentration of emulsifiers significantly impact ice cream's consistency, shelf life, and overall sensory experience.

Choosing the Right Additive: Stabilizer or Emulsifier?

Choosing the right additive for ice cream consistency control depends on the desired texture and stability; stabilizers like guar gum or carrageenan improve water retention and prevent ice crystal growth, resulting in a smoother, creamier product. Emulsifiers such as lecithin and mono- and diglycerides enhance fat dispersion and air incorporation, promoting a uniform structure and improved mouthfeel. Understanding the specific roles of stabilizers versus emulsifiers ensures optimal ice cream quality by balancing viscosity, creaminess, and shelf-life stability.

Effects of Improper Use on Ice Cream Quality

Improper use of stabilizers in ice cream can lead to undesirable texture issues such as iciness and sandiness due to inadequate water binding and ice crystal control. Overuse or misuse of emulsifiers may cause a greasy mouthfeel and negatively impact the air incorporation, resulting in reduced overrun and poor creaminess. Both stabilizer and emulsifier imbalances disrupt the delicate microstructure, compromising the overall sensory quality and shelf life of the ice cream.

Stabilizer vs Emulsifier for consistency control Infographic

cookingyes.com

cookingyes.com