A hardening tunnel provides gradual cooling that enhances ice cream texture by minimizing ice crystal formation, ensuring smoothness and creaminess. In contrast, a blast freezer rapidly freezes ice cream, which is ideal for mass production but may result in a slightly coarser texture. Selecting between a hardening tunnel and a blast freezer depends on the desired balance of production speed and product quality.

Table of Comparison

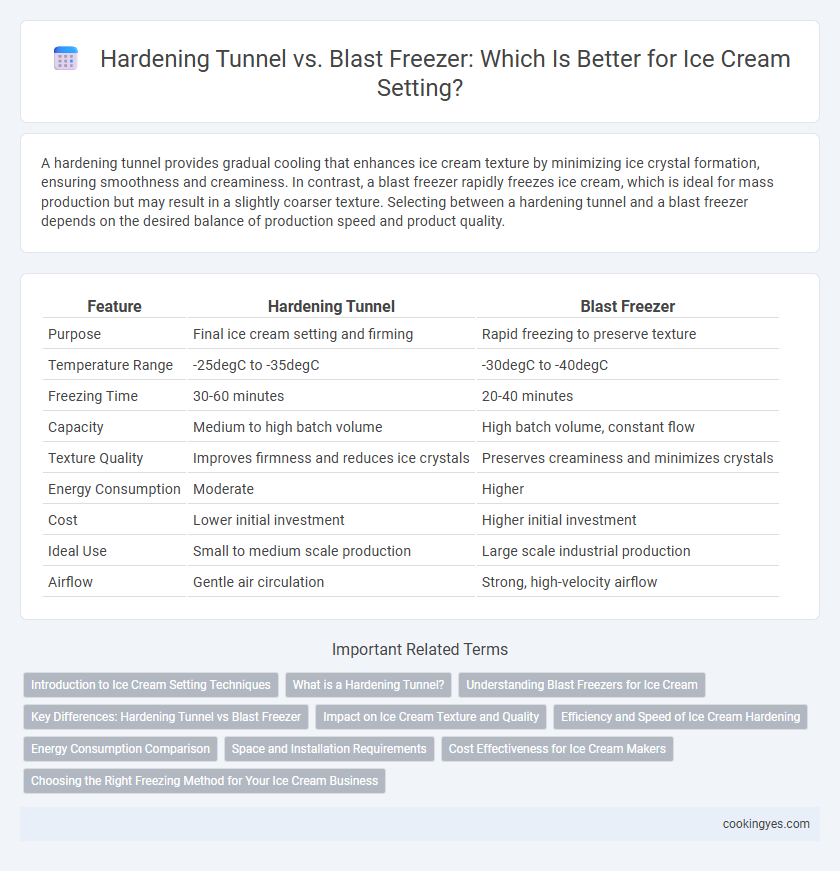

| Feature | Hardening Tunnel | Blast Freezer |

|---|---|---|

| Purpose | Final ice cream setting and firming | Rapid freezing to preserve texture |

| Temperature Range | -25degC to -35degC | -30degC to -40degC |

| Freezing Time | 30-60 minutes | 20-40 minutes |

| Capacity | Medium to high batch volume | High batch volume, constant flow |

| Texture Quality | Improves firmness and reduces ice crystals | Preserves creaminess and minimizes crystals |

| Energy Consumption | Moderate | Higher |

| Cost | Lower initial investment | Higher initial investment |

| Ideal Use | Small to medium scale production | Large scale industrial production |

| Airflow | Gentle air circulation | Strong, high-velocity airflow |

Introduction to Ice Cream Setting Techniques

Hardening tunnels and blast freezers play crucial roles in ice cream setting by rapidly lowering temperature to stabilize texture and prevent ice crystal growth. Hardening tunnels use a continuous airflow system maintaining temperatures between -30degC to -40degC, ideal for small to medium-scale production with consistent gelato and ice cream firmness. Blast freezers, typically operating below -40degC, provide ultra-fast freezing suitable for large batches, preserving quality while enhancing shelf life.

What is a Hardening Tunnel?

A hardening tunnel is a specialized freezing chamber designed to rapidly solidify ice cream by exposing it to extremely low temperatures and high airflow, typically around -30degC to -40degC. This process quickly stabilizes the product's texture, preventing ice crystal growth and preserving a smooth, creamy consistency. Compared to a blast freezer, a hardening tunnel offers more precise temperature control and airflow management, optimizing the setting phase for high-quality ice cream production.

Understanding Blast Freezers for Ice Cream

Blast freezers rapidly reduce ice cream temperature to around -30degC, preventing large ice crystals and enhancing texture and creaminess. Unlike hardening tunnels that use slower cooling methods, blast freezers ensure uniform freezing and faster setting, preserving the product's quality and shelf life. Optimal blast freezer settings improve structural integrity and maintain smooth, creamy consistency in premium ice cream production.

Key Differences: Hardening Tunnel vs Blast Freezer

Hardening tunnels rapidly cool ice cream by circulating cold air at moderate speeds, achieving surface hardening while preserving texture. Blast freezers use extremely low temperatures and high-velocity airflow to freeze ice cream quickly, producing a denser, more stable product with reduced ice crystal size. The key difference lies in their freezing rates and airflow intensity, affecting the ice cream's texture and shelf life.

Impact on Ice Cream Texture and Quality

Hardening tunnels provide gradual temperature reduction, promoting uniform crystal formation and resulting in a smoother, creamier ice cream texture. Blast freezers rapidly freeze ice cream, which minimizes ice crystal size but may cause surface cracking or uneven firmness if not precisely controlled. Optimal ice cream quality depends on balancing freezing speed with temperature consistency to preserve texture and prevent structural damage.

Efficiency and Speed of Ice Cream Hardening

Hardening tunnels offer rapid ice cream setting by circulating cold air at temperatures around -25degC to -30degC, enabling efficient hardening within 15 to 30 minutes. Blast freezers operate at even lower temperatures, typically between -35degC and -40degC, accelerating the freezing process to under 15 minutes and improving ice crystal size reduction for better texture. Both systems optimize production speed, but blast freezers provide superior efficiency in minimizing freezing time and enhancing ice cream quality in high-volume operations.

Energy Consumption Comparison

Hardening tunnels typically consume more energy due to longer cooling cycles required to gradually solidify ice cream, whereas blast freezers use powerful, rapid cooling fans that lower temperatures quickly, resulting in shorter freeze times and lower overall energy usage. Blast freezers maintain a more consistent cold airflow that improves thermal efficiency, reducing energy costs by up to 30% compared to traditional hardening tunnels. Energy-efficient blast freezing technology not only accelerates ice cream setting but also minimizes operational expenses in commercial production facilities.

Space and Installation Requirements

Hardening tunnels require significantly more space due to their longer conveyor systems and larger footprint compared to compact blast freezers designed for quick freezing in confined areas. Installation of hardening tunnels often involves complex integration with production lines and requires specialized utilities, whereas blast freezers are modular, easier to install, and adaptable to existing facility layouts. The choice between the two impacts factory floor planning, with blast freezers offering a more flexible, space-efficient solution for ice cream setting.

Cost Effectiveness for Ice Cream Makers

Hardening tunnels offer cost-effective solutions for small to medium ice cream makers by using lower energy consumption and requiring less specialized equipment compared to blast freezers. Blast freezers provide faster freezing times and better texture preservation but come with higher initial investment and operational costs, making them ideal for large-scale production facilities. Ice cream manufacturers must balance throughput needs and budget constraints when choosing between hardening tunnels and blast freezers for optimal cost efficiency.

Choosing the Right Freezing Method for Your Ice Cream Business

Choosing between a hardening tunnel and a blast freezer depends on the scale and speed requirements of your ice cream business. Hardening tunnels provide consistent temperature and airflow, ideal for rapid surface freezing and maintaining product shape, while blast freezers offer ultra-fast freezing that preserves texture and prevents large ice crystals. Businesses prioritizing high volume with quick turnover often benefit from blast freezers, whereas smaller-scale operations may find hardening tunnels sufficient for quality texture and cost efficiency.

Hardening tunnel vs Blast freezer for ice cream setting Infographic

cookingyes.com

cookingyes.com