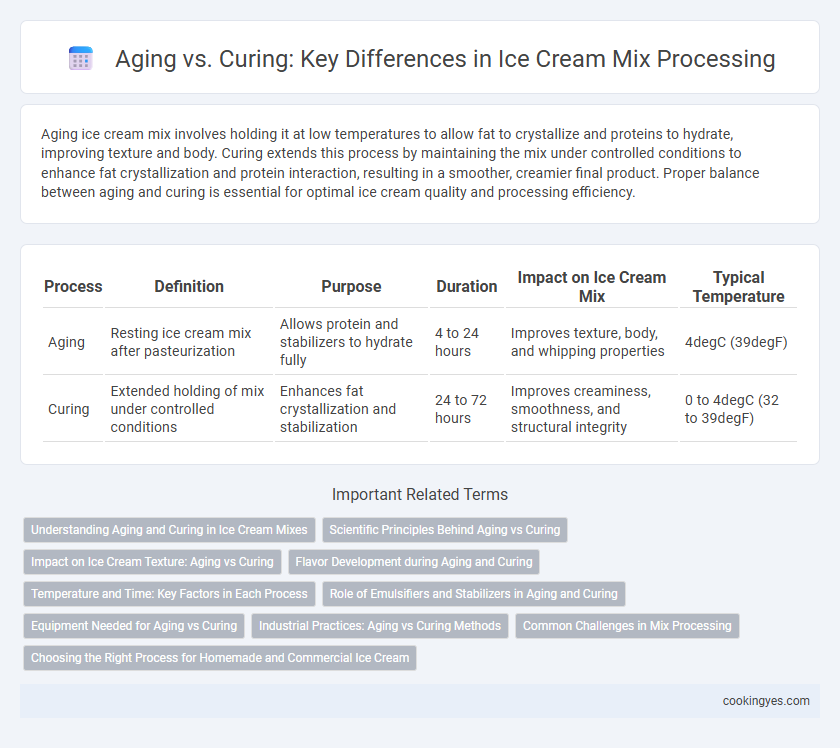

Aging ice cream mix involves holding it at low temperatures to allow fat to crystallize and proteins to hydrate, improving texture and body. Curing extends this process by maintaining the mix under controlled conditions to enhance fat crystallization and protein interaction, resulting in a smoother, creamier final product. Proper balance between aging and curing is essential for optimal ice cream quality and processing efficiency.

Table of Comparison

| Process | Definition | Purpose | Duration | Impact on Ice Cream Mix | Typical Temperature |

|---|---|---|---|---|---|

| Aging | Resting ice cream mix after pasteurization | Allows protein and stabilizers to hydrate fully | 4 to 24 hours | Improves texture, body, and whipping properties | 4degC (39degF) |

| Curing | Extended holding of mix under controlled conditions | Enhances fat crystallization and stabilization | 24 to 72 hours | Improves creaminess, smoothness, and structural integrity | 0 to 4degC (32 to 39degF) |

Understanding Aging and Curing in Ice Cream Mixes

Aging in ice cream mix processing involves holding the mixture at low temperatures, typically between 4degC to 6degC, for 4 to 24 hours to allow fat crystallization and protein hydration, which enhances texture and whipping properties. Curing refers to the extended refrigeration of the mix beyond aging, promoting flavor development through enzymatic reactions and stabilizing the emulsion. Understanding these processes ensures optimal ice crystal size, mouthfeel, and overall product quality in commercial ice cream production.

Scientific Principles Behind Aging vs Curing

Aging ice cream mix involves holding the mixture at low temperatures (around 0-5degC) for 4-24 hours to allow milk proteins and stabilizers to hydrate fully, enhancing viscosity and improving the ice cream's texture and overrun. Curing, on the other hand, refers to extending the aging time or incorporating additional biochemical reactions such as protein aggregation and fat crystallization to develop more complex textures and flavors. The scientific principles behind aging versus curing focus on molecular interactions in the mix, including protein unfolding, fat destabilization, and polysaccharide gel formation, which collectively optimize the mix's freezing behavior and final product quality.

Impact on Ice Cream Texture: Aging vs Curing

Aging the ice cream mix involves holding it at refrigerated temperatures (around 4degC) for several hours to hydrate proteins and stabilize fat, resulting in a creamier, smoother texture by improving fat crystallization. Curing, typically performed at slightly higher temperatures or for shorter periods, enhances the mix's viscosity and overrun, but may produce a denser texture compared to properly aged mixes. Optimizing aging parameters directly influences ice cream texture by promoting air incorporation and stable ice crystal formation, whereas curing primarily affects mix firmness and melting resistance.

Flavor Development during Aging and Curing

Aging ice cream mix allows proteins and fat to hydrate, enhancing texture and promoting enzymatic reactions that deepen flavor complexity. During curing, extended rest at low temperatures enables microbial fermentation and flavor precursor development, resulting in richer, more balanced taste profiles. Both processes are crucial for maximizing flavor development by improving ingredient interaction and biochemical transformation in the ice cream base.

Temperature and Time: Key Factors in Each Process

Aging ice cream mix involves maintaining a temperature of 0degC to 4degC for 4 to 24 hours, allowing milk proteins and fat to fully hydrate and stabilize the mixture. Curing focuses on extended time, often several hours to days at slightly higher temperatures around 5degC to 8degC, which promotes flavor development and improves texture. Precise control of temperature and timing in both aging and curing stages is essential to ensure optimal creaminess, smoothness, and air incorporation in the final ice cream product.

Role of Emulsifiers and Stabilizers in Aging and Curing

Emulsifiers and stabilizers play a crucial role during the aging and curing phases of ice cream mix processing by enhancing fat destabilization and improving mix viscosity. Aging allows emulsifiers to promote partial coalescence of fat globules, leading to better air incorporation and creaminess, while stabilizers increase water-binding capacity to prevent ice crystal growth during curing. Effective interaction of these ingredients improves overall texture, melt resistance, and shelf life of the final ice cream product.

Equipment Needed for Aging vs Curing

Aging ice cream mix requires equipment such as refrigerated aging tanks or vats that maintain consistent low temperatures, ensuring protein and fat stabilization for improved texture. Curing involves specialized, precisely controlled temperature storage units or curing chambers designed to develop flavor and improve mix consistency over extended periods. Both processes rely on equipment that supports temperature control but differ in duration and specific environmental requirements for optimal ice cream quality.

Industrial Practices: Aging vs Curing Methods

Industrial practices in ice cream mix processing prioritize aging to enhance fat crystallization and protein dispersion, improving texture and whipping properties. Curing methods, involving controlled rest periods at specific temperatures, allow for the maturation of milk proteins and fat globules, resulting in a smoother mouthfeel and increased overrun. Efficient aging and curing protocols optimize mix stability and sensory quality, crucial for large-scale ice cream production.

Common Challenges in Mix Processing

Aging and curing ice cream mix are critical stages that influence texture and stability, yet both present common challenges such as maintaining consistent temperature and preventing microbial growth. Failure to properly control aging duration can result in inadequate protein hydration, affecting mix viscosity and overrun during freezing. Curing requires precise timing to enhance fat crystallization and flavor development, with deviations potentially causing defects like grittiness or inconsistent melt resistance.

Choosing the Right Process for Homemade and Commercial Ice Cream

Aging ice cream mix involves holding the blend at refrigeration temperature (around 4degC) for 4 to 24 hours, allowing fat to crystallize and proteins to fully hydrate, resulting in a smoother texture and improved body. Curing, more common in commercial processing, entails prolonged aging and controlled microbial development that enhances flavor complexity and stability in large-scale production. Choosing aging for homemade batches ensures easier handling and better aeration, while curing suits commercial operations seeking consistent texture and flavor across large volumes.

Aging vs Curing for ice cream mix processing Infographic

cookingyes.com

cookingyes.com