Hand-rolled bagels offer a unique texture and authentic flavor due to the artisanal shaping process, which creates an uneven, chewy crust and distinctive air pockets. Machine-formed bagels provide consistent size and shape, ensuring uniform baking and faster production suitable for large-scale distribution. Choosing between hand-rolled and machine-formed bagels depends on prioritizing traditional craftsmanship or efficiency and consistency in bagel quality.

Table of Comparison

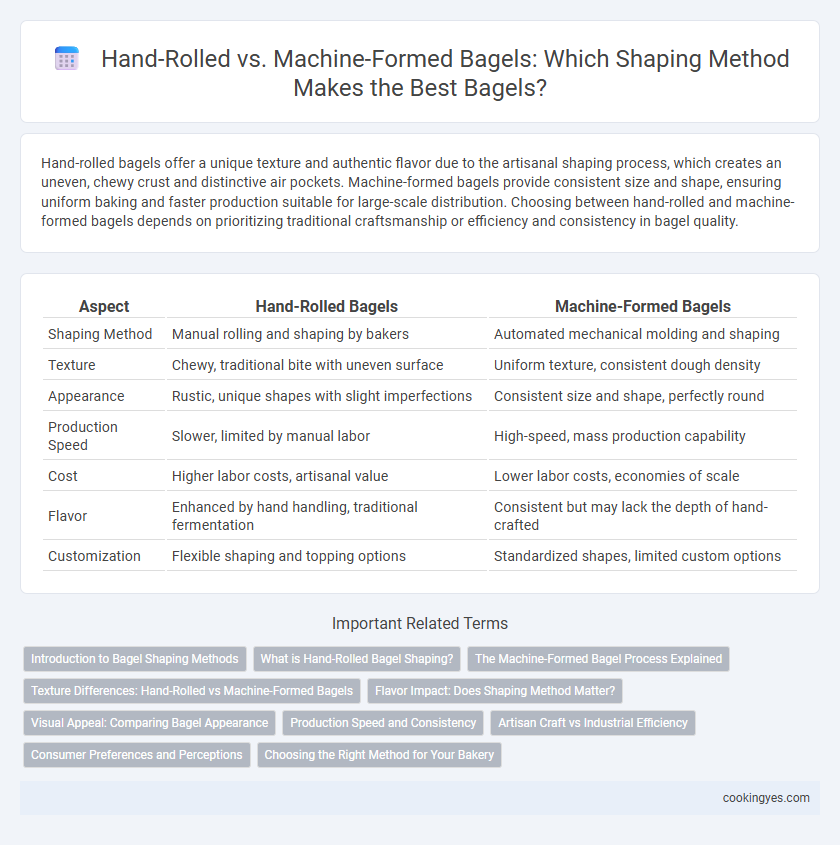

| Aspect | Hand-Rolled Bagels | Machine-Formed Bagels |

|---|---|---|

| Shaping Method | Manual rolling and shaping by bakers | Automated mechanical molding and shaping |

| Texture | Chewy, traditional bite with uneven surface | Uniform texture, consistent dough density |

| Appearance | Rustic, unique shapes with slight imperfections | Consistent size and shape, perfectly round |

| Production Speed | Slower, limited by manual labor | High-speed, mass production capability |

| Cost | Higher labor costs, artisanal value | Lower labor costs, economies of scale |

| Flavor | Enhanced by hand handling, traditional fermentation | Consistent but may lack the depth of hand-crafted |

| Customization | Flexible shaping and topping options | Standardized shapes, limited custom options |

Introduction to Bagel Shaping Methods

Hand-rolled bagel shaping creates a denser, chewier texture by manually forming dough into rings, offering greater control over thickness and size. Machine-formed bagels provide consistent shapes and uniform baking but may sacrifice artisan texture and traditional hand-crafted appearance. Choosing between methods impacts dough elasticity, crust development, and final product authenticity.

What is Hand-Rolled Bagel Shaping?

Hand-rolled bagel shaping involves manually stretching and forming dough into a ring shape, ensuring a denser, chewier texture and a more artisanal appearance. This traditional method allows for greater control over dough consistency and thickness, resulting in a distinctive crust and unique mouthfeel compared to machine-formed bagels. Hand-rolled bagels often retain irregularities that enhance their authentic taste and visual appeal, prized by craft bakers and enthusiasts.

The Machine-Formed Bagel Process Explained

The machine-formed bagel process involves dough being portioned and shaped by automated equipment, ensuring uniform size and consistent texture across batches. Industrial machines use extrusion or molding techniques to create the traditional ring shape efficiently, minimizing manual labor and production time. This method maintains high throughput and quality control, essential for large-scale bagel manufacturing while preserving the dense, chewy crumb characteristic of classic bagels.

Texture Differences: Hand-Rolled vs Machine-Formed Bagels

Hand-rolled bagels feature a denser, chewier texture due to the manual stretching and shaping process that allows for better gluten development and air retention. Machine-formed bagels tend to have a more uniform shape with a slightly lighter, less chewy texture, resulting from mechanized shaping that can compress the dough more evenly but less organically. Texture quality in hand-rolled bagels is often preferred by artisans and consumers seeking traditional bagel chewiness and a robust crust.

Flavor Impact: Does Shaping Method Matter?

Hand-rolled bagels often develop a denser crumb and slightly chewier texture due to the artisanal dough manipulation, enhancing the overall flavor complexity through more even gluten development. Machine-formed bagels, while consistent in shape and size, may yield a lighter bite and less pronounced crust, potentially diminishing the rich, toasty notes associated with traditional bagels. The shaping method directly influences fermentation and baking behavior, making hand-rolled techniques preferable for those seeking authentic, robust bagel flavors.

Visual Appeal: Comparing Bagel Appearance

Hand-rolled bagels exhibit a rustic and artisanal appearance with slight variations in shape and thickness that highlight their handcrafted nature. Machine-formed bagels offer a consistently uniform size and smooth, symmetrical surface, providing a polished look favored in commercial settings. Visual appeal in bagels depends on the intended market, with hand-rolled bagels appealing to consumers valuing authenticity and machine-formed bagels attracting those seeking consistency.

Production Speed and Consistency

Hand-rolled bagels offer artisanal quality and unique texture variations, but require significantly more production time and skilled labor. Machine-formed bagels enable high-speed production with consistent size and shape, essential for large-scale commercial bakeries. The choice between methods balances traditional craftsmanship against efficiency and uniformity in output.

Artisan Craft vs Industrial Efficiency

Hand-rolled bagels showcase artisan craftsmanship, offering a denser texture and unique irregularities that enhance flavor and authenticity. Machine-formed bagels emphasize industrial efficiency, ensuring consistent size and shape, speeding up production while sacrificing some traditional qualities. The choice between methods impacts both the eating experience and bakery workflow, balancing heritage with scalability.

Consumer Preferences and Perceptions

Consumers often perceive hand-rolled bagels as more authentic and artisanal due to their irregular shape and denser texture, which suggests traditional craftsmanship. Machine-formed bagels tend to attract buyers seeking uniformity and consistency in size and texture, appealing to those preferring convenience and predictability. Market research shows a growing preference for hand-rolled bagels among niche artisan food markets, attributed to an increasing demand for premium, handmade products.

Choosing the Right Method for Your Bakery

Hand-rolled bagels offer a traditional texture with a denser crumb and chewier exterior, appealing to artisanal bakeries seeking authenticity. Machine-formed bagels provide consistency in size and shape, increasing efficiency and throughput for high-volume bakeries. Selecting between hand-rolled and machine-formed methods depends on balancing desired product quality with production capacity and operational priorities.

Hand-rolled vs machine-formed for bagel shaping Infographic

cookingyes.com

cookingyes.com