Teburi udon noodles are hand-crafted through a traditional kneading and rolling technique, resulting in a unique, irregular texture that enhances the noodle's ability to absorb broth. Machine-cut udon offers consistency in thickness and uniformity, providing a smooth, even bite preferred in many modern kitchens. While teburi emphasizes artisanal quality and a chewy, rustic mouthfeel, machine-cut udon prioritizes efficiency and standardized texture for mass production.

Table of Comparison

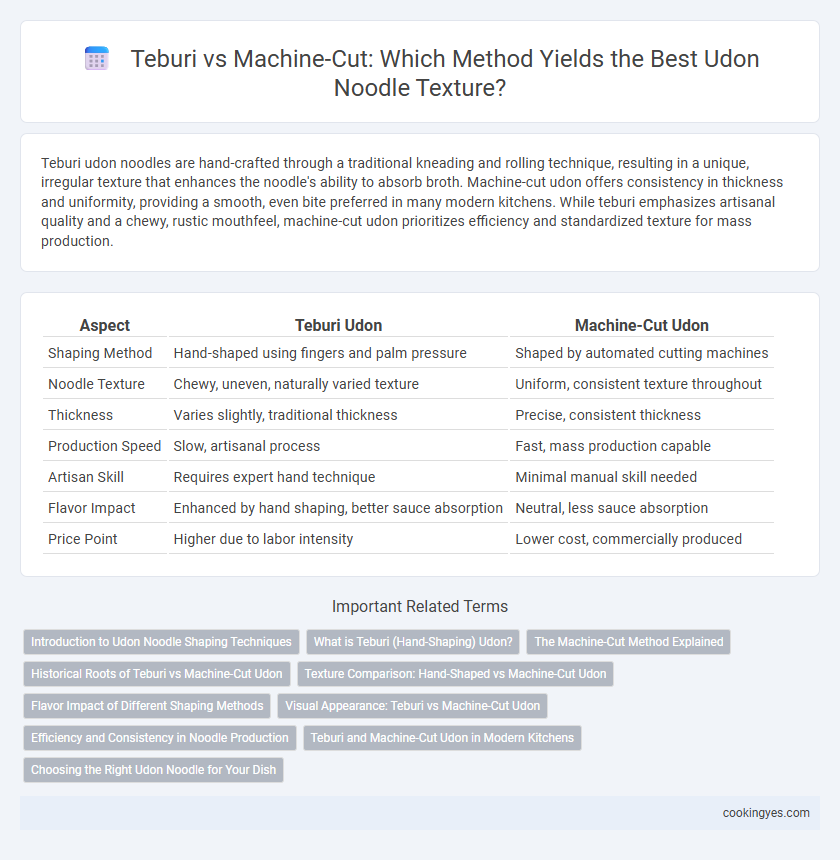

| Aspect | Teburi Udon | Machine-Cut Udon |

|---|---|---|

| Shaping Method | Hand-shaped using fingers and palm pressure | Shaped by automated cutting machines |

| Noodle Texture | Chewy, uneven, naturally varied texture | Uniform, consistent texture throughout |

| Thickness | Varies slightly, traditional thickness | Precise, consistent thickness |

| Production Speed | Slow, artisanal process | Fast, mass production capable |

| Artisan Skill | Requires expert hand technique | Minimal manual skill needed |

| Flavor Impact | Enhanced by hand shaping, better sauce absorption | Neutral, less sauce absorption |

| Price Point | Higher due to labor intensity | Lower cost, commercially produced |

Introduction to Udon Noodle Shaping Techniques

Teburi udon noodle shaping involves hand-pulling and stretching the dough, creating a chewy texture that retains slight irregularities for enhanced mouthfeel. Machine-cut udon employs precision cutting tools, producing uniformly thick noodles that offer consistency in cooking and presentation. Both techniques highlight traditional craftsmanship versus industrial efficiency in udon noodle production.

What is Teburi (Hand-Shaping) Udon?

Teburi udon is a traditional Japanese hand-shaping technique where skilled artisans meticulously stretch and shape dough using their hands, resulting in noodles with a unique texture and elasticity. Unlike machine-cut udon, Teburi creates uneven, thicker strands that enhance the chewiness and absorbency, offering a more authentic and artisanal eating experience. This method emphasizes craftsmanship, preserving the natural gluten development and maintaining a distinct bite that machines often cannot replicate.

The Machine-Cut Method Explained

The machine-cut method for shaping udon noodles involves using automated blades to slice the dough into uniform strands, ensuring consistent thickness and texture. This technique enhances production efficiency, making it ideal for large-scale manufacturing and maintaining quality control. Compared to the traditional teburi hand-rolling method, machine-cut udon offers precise, repeatable cuts that cater to modern demand and commercial distribution.

Historical Roots of Teburi vs Machine-Cut Udon

Teburi udon, shaped by hand using traditional pinching and rolling techniques, dates back centuries and reflects the artisanal craftsmanship of Japanese noodle makers. Machine-cut udon, introduced during Japan's rapid industrialization in the early 20th century, revolutionized production by standardizing thickness and boosting output to meet growing demand. The historical roots of teburi highlight cultural preservation, while machine-cut methods emphasize efficiency and mass accessibility.

Texture Comparison: Hand-Shaped vs Machine-Cut Udon

Teburi, or hand-shaped udon, offers a chewier, more uneven texture that highlights the noodle's artisanal quality and enhances mouthfeel. Machine-cut udon provides uniform thickness and a consistent bite, resulting in a smoother texture ideal for large-scale production and quick cooking. Texture in teburi udon tends to be more resilient and springy due to varying thickness, while machine-cut noodles emphasize uniformity and ease of culinary use.

Flavor Impact of Different Shaping Methods

Teburi, the traditional hand-shaping method for udon noodles, creates a denser texture that enhances flavor absorption and delivers a richer taste experience compared to machine-cut udon. Machine-cut udon offers uniform thickness and consistency but often results in a less chewy texture, slightly diminishing the noodle's ability to hold rich broths and sauces. The subtle irregularities in teburi strands trap broth more effectively, intensifying each bite's umami and mouthfeel.

Visual Appearance: Teburi vs Machine-Cut Udon

Teburi udon noodles exhibit a rustic, uneven texture with slight variations in thickness, contributing to an artisanal, handcrafted visual appeal prized by traditionalists. Machine-cut udon offers uniform thickness and smooth edges, creating a consistent, polished appearance favored in commercial settings. The choice between Teburi and machine-cut styles significantly impacts presentation, with Teburi highlighting natural imperfection and machine-cut emphasizing precision.

Efficiency and Consistency in Noodle Production

Teburi udon shaping, a traditional hand-pulling method, offers artisanal texture and subtle variations favored in premium noodle production but requires significant labor and time, limiting efficiency. Machine-cut udon provides high consistency in noodle thickness and shape while dramatically increasing production speed, making it ideal for large-scale manufacturing. Balancing craftsmanship with mass production needs, many producers combine teburi techniques for specialty batches and machine-cut processes for standard product lines to optimize quality and output.

Teburi and Machine-Cut Udon in Modern Kitchens

Teburi udon features hand-crafted, artful noodle shaping that enhances texture and chewiness, prized in artisanal kitchens for its authentic mouthfeel. Machine-cut udon offers uniform thickness and consistent cooking times, ideal for high-volume modern kitchens seeking efficiency and standardization. Both methods influence udon quality and kitchen workflow, with Teburi emphasizing traditional craftsmanship and machine-cut prioritizing scalability in contemporary culinary settings.

Choosing the Right Udon Noodle for Your Dish

Teburi udon noodles, hand-shaped through traditional kneading and rolling, offer a chewy texture and irregular thickness that enhances the noodle's ability to absorb rich, savory broths, making them ideal for hearty dishes like kitsune or curry udon. Machine-cut udon provides uniform thickness and consistent texture, perfect for cold udon dishes or soups where even cooking time and presentation are essential. Selecting between teburi and machine-cut depends on the desired mouthfeel and dish style, with teburi emphasizing artisanal quality and machine-cut prioritizing consistency.

Teburi vs Machine-cut for udon noodle shaping Infographic

cookingyes.com

cookingyes.com