Hand-rolling spring rolls allows for precise control over the thickness and tightness of each roll, resulting in a delicate texture and a personalized touch to the filling distribution. Machine-rolling, on the other hand, offers consistent size and speed, making it ideal for large-scale production without compromising on uniformity. Choosing between hand-rolling and machine-rolling depends on whether the priority is artisanal quality or efficiency in spring roll preparation.

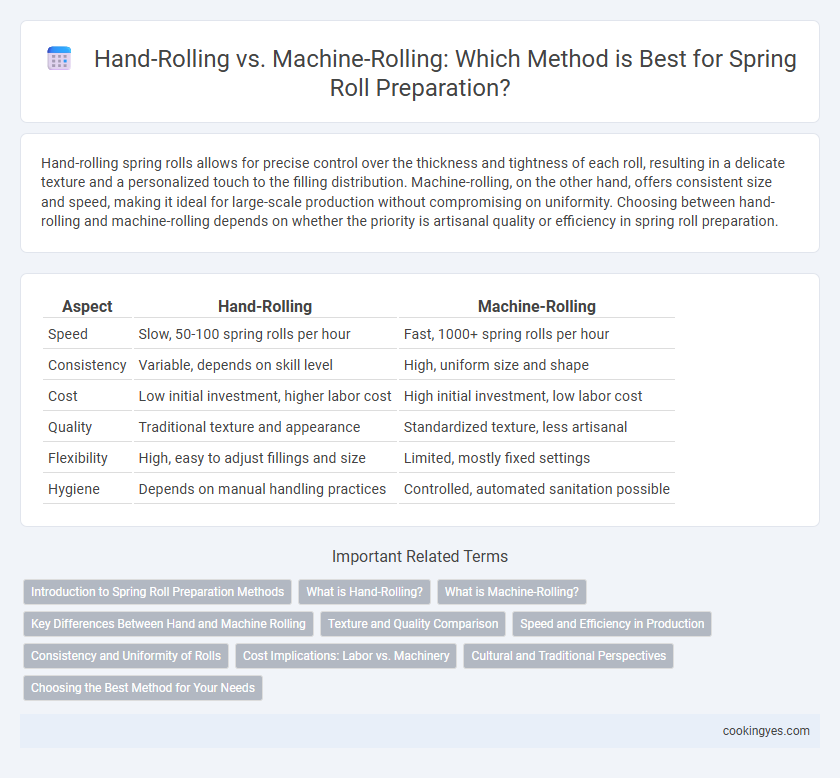

Table of Comparison

| Aspect | Hand-Rolling | Machine-Rolling |

|---|---|---|

| Speed | Slow, 50-100 spring rolls per hour | Fast, 1000+ spring rolls per hour |

| Consistency | Variable, depends on skill level | High, uniform size and shape |

| Cost | Low initial investment, higher labor cost | High initial investment, low labor cost |

| Quality | Traditional texture and appearance | Standardized texture, less artisanal |

| Flexibility | High, easy to adjust fillings and size | Limited, mostly fixed settings |

| Hygiene | Depends on manual handling practices | Controlled, automated sanitation possible |

Introduction to Spring Roll Preparation Methods

Hand-rolling spring rolls allows for precise control of texture and fillings, preserving traditional craftsmanship and freshness. Machine-rolling increases production speed and uniformity, ideal for large-scale operations while maintaining consistent shape and size. Both methods impact the final product's taste, appearance, and overall quality, influencing consumer preference and market demand.

What is Hand-Rolling?

Hand-rolling spring rolls involves manually wrapping fresh ingredients in rice paper or wheat wrappers, allowing precise control over the texture and filling distribution. This traditional technique enhances the structural integrity and visual appeal, ensuring each roll is tightly sealed for optimal freshness. Expert hand-rollers can customize sizes and ingredient ratios, resulting in a superior taste experience compared to uniform machine-rolled options.

What is Machine-Rolling?

Machine-rolling for spring roll preparation involves using automated equipment to uniformly shape and wrap the fillings, ensuring consistent size and texture across each roll. This method significantly increases production speed and reduces labor costs compared to traditional hand-rolling techniques. Machine-rolled spring rolls often maintain structural integrity while catering to high-volume commercial demands without compromising quality.

Key Differences Between Hand and Machine Rolling

Hand-rolling spring rolls allows for greater precision and customization in size, filling distribution, and texture, often resulting in a more authentic and artisanal product. Machine-rolling offers high-speed production with consistent shape and tight sealing, suitable for large-scale manufacturing but may sacrifice subtle variations in taste and appearance. The key differences between hand and machine rolling lie in control over detail, production volume, and uniformity of the spring rolls.

Texture and Quality Comparison

Hand-rolling spring rolls produces a delicate texture with thin, evenly wrapped layers that enhance crispness and retain a fresh, tender bite. Machine-rolled spring rolls often have uniform shape and size but may compromise texture, resulting in thicker, denser wrappers that can affect overall mouthfeel and crispiness. Quality in hand-rolled spring rolls is generally higher due to meticulous attention to ingredient placement, ensuring balanced filling distribution and a superior eating experience.

Speed and Efficiency in Production

Hand-rolling spring rolls offers greater control over ingredient distribution and customization but significantly limits production speed, making it less efficient for large-scale operations. Machine-rolling systems can produce hundreds of spring rolls per hour with consistent size and tight wrapping, dramatically increasing throughput in commercial settings. Automated processes reduce labor costs and minimize variability, optimizing overall efficiency in high-demand production environments.

Consistency and Uniformity of Rolls

Hand-rolling spring rolls often results in slight variations in size and filling distribution, affecting consistency and uniformity across batches. Machine-rolling ensures highly uniform rolls with standardized dimensions and tightly packed fillings, improving presentation and cooking evenness. This precision in machine-rolling enhances quality control, especially crucial for commercial production.

Cost Implications: Labor vs. Machinery

Hand-rolling spring rolls requires significant labor hours, increasing overall production costs due to skilled manual work and slower throughput. Machine-rolling reduces labor expenses by automating the process, offering higher efficiency and consistent quality, though initial investment and maintenance costs for machinery can be substantial. Balancing these cost implications depends on production volume, with manual rolling favored for small batches and machine-rolling more cost-effective for large-scale operations.

Cultural and Traditional Perspectives

Hand-rolling spring rolls preserves the cultural authenticity and traditional craftsmanship passed down through generations, emphasizing the artisanal skill and attention to detail in each roll. Machine-rolling, while efficient for mass production, often lacks the delicate touch and subtle variations prized in traditional spring roll preparation, potentially diminishing the unique textures and flavors. Embracing hand-rolling supports the preservation of culinary heritage, sustaining the cultural significance embedded in the spring roll-making process.

Choosing the Best Method for Your Needs

Hand-rolling spring rolls allows for greater control over ingredient placement and customization, resulting in a more authentic texture and appearance. Machine-rolling offers consistent size and faster production, making it ideal for commercial kitchens or large batches. Choosing the best method depends on the desired quality, volume, and available time for preparation.

Hand-rolling vs machine-rolling for spring roll preparation Infographic

cookingyes.com

cookingyes.com