Hand-carved shawarma offers a traditional texture and flavor, with each slice retaining a slightly irregular thickness that enhances the meat's juiciness and caramelization. Machine-sliced shawarma provides consistent thickness, ensuring even cooking and efficient preparation for high-volume service without compromising taste. Choosing between hand-carving and machine slicing affects the shawarma's texture, cooking precision, and overall dining experience.

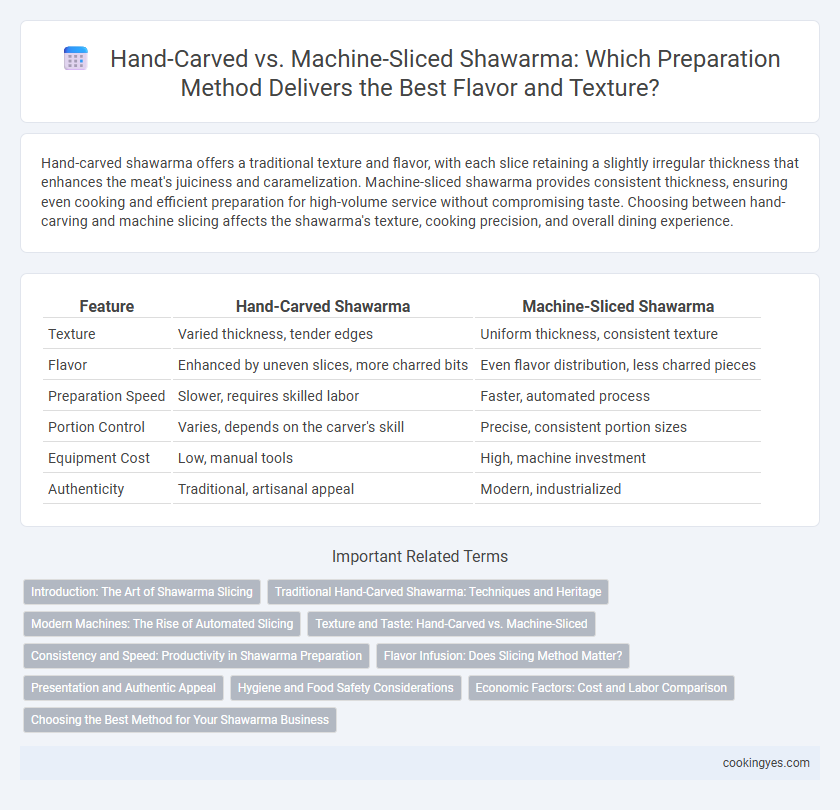

Table of Comparison

| Feature | Hand-Carved Shawarma | Machine-Sliced Shawarma |

|---|---|---|

| Texture | Varied thickness, tender edges | Uniform thickness, consistent texture |

| Flavor | Enhanced by uneven slices, more charred bits | Even flavor distribution, less charred pieces |

| Preparation Speed | Slower, requires skilled labor | Faster, automated process |

| Portion Control | Varies, depends on the carver's skill | Precise, consistent portion sizes |

| Equipment Cost | Low, manual tools | High, machine investment |

| Authenticity | Traditional, artisanal appeal | Modern, industrialized |

Introduction: The Art of Shawarma Slicing

Hand-carved shawarma preserves traditional techniques, allowing skilled chefs to slice meat with precision, enhancing texture and flavor. Machine-sliced shawarma offers consistency and speed, ideal for high-volume service while maintaining uniform thickness. Optimal slicing impacts juiciness, tenderness, and the overall eating experience, reflecting the artisan quality in shawarma preparation.

Traditional Hand-Carved Shawarma: Techniques and Heritage

Traditional hand-carved shawarma preserves authentic techniques that enhance the meat's texture and flavor by slicing thin, uneven pieces directly from the rotating spit. This artisanal method reflects a rich culinary heritage passed down through generations, emphasizing skillful precision and maintaining the meat's juiciness. Hand-carving ensures a unique eating experience, distinguishing traditional shawarma from machine-sliced alternatives by offering superior tenderness and depth of taste.

Modern Machines: The Rise of Automated Slicing

Modern machines for shawarma slicing provide consistent thickness and speed, enhancing efficiency in busy kitchens. Automated slicing reduces labor costs and minimizes human error, ensuring uniform meat portions that maintain flavor and texture. These advancements support higher volume production while preserving the traditional taste cherished in authentic shawarma.

Texture and Taste: Hand-Carved vs. Machine-Sliced

Hand-carved shawarma offers a distinct texture with irregular, thicker cuts that retain juiciness and a richer, more authentic flavor profile. Machine-sliced shawarma provides uniform, thinner slices that cook evenly but may lack the depth of taste and varied texture found in hand-carved meat. The artisanal approach enhances the sensory experience by preserving natural meat fibers and delivering a more satisfying chew.

Consistency and Speed: Productivity in Shawarma Preparation

Machine-sliced shawarma ensures consistent thickness and uniform cooking, leading to faster and more reliable preparation times. Hand-carved shawarma offers artisanal texture and flavor variation but can result in uneven slices that slow down productivity. Optimizing for speed and consistency, many commercial kitchens prefer machine slicing to meet high-volume demand efficiently.

Flavor Infusion: Does Slicing Method Matter?

Hand-carved shawarma allows for thicker, uneven slices that retain more juices and provide a richer flavor infusion, enhancing the meat's natural taste. Machine-sliced shawarma offers uniform, thinner cuts that cook evenly but may result in less moisture retention, potentially diluting flavor intensity. The slicing method influences flavor absorption from spices and marinades, with hand-carving generally preserving a deeper, more pronounced shawarma taste.

Presentation and Authentic Appeal

Hand-carved shawarma offers a traditional, artisanal presentation with uneven, irregular slices that enhance the authentic appeal and texture experience. Machine-sliced shawarma provides uniform thickness and consistency, which can improve efficiency but may lack the rustic charm that hand-carving delivers. The visual and tactile contrast between hand-carved and machine-sliced shawarma directly influences customer perception of authenticity and quality.

Hygiene and Food Safety Considerations

Hand-carving shawarma ensures precise control over meat quality but requires strict hygiene protocols, including frequent hand washing and sanitized knives, to prevent cross-contamination. Machine slicing offers consistent thickness and speed, minimizing direct contact and reducing bacterial transfer risks, though machines demand regular cleaning to avoid residue buildup and contamination. Both methods must adhere to food safety standards such as maintaining proper meat temperature and sanitation to ensure safe consumption.

Economic Factors: Cost and Labor Comparison

Hand-carved shawarma offers a traditional, artisanal quality but demands skilled labor, increasing operational costs and limiting scalability. Machine-sliced shawarma significantly reduces labor expenses and processing time, enhancing efficiency and consistency in volume production. Economic factors favor machine-slicing for cost-effective large-scale operations, while hand-carving remains niche for premium pricing.

Choosing the Best Method for Your Shawarma Business

Hand-carved shawarma offers superior flavor and texture, preserving the juiciness of marinated meat with precise, artisanal cutting techniques favored by traditional eateries. Machine-sliced methods provide consistency and speed, optimizing production volume for high-demand shawarma businesses while maintaining uniform thickness. Selecting the best slicing method depends on balancing quality expectations, operational efficiency, and customer preferences to enhance overall product appeal and business scalability.

Hand-carved vs machine-sliced for shawarma preparation Infographic

cookingyes.com

cookingyes.com