Hand-cut ravioli offers artisanal precision and unique shapes that enhance texture, while machine-cut ravioli ensures uniformity and faster production ideal for large batches. The choice between hand-cut and machine-cut affects the final product's appearance, cooking consistency, and overall quality. Understanding these differences allows producers to select a method that aligns with their desired ravioli characteristics and production scale.

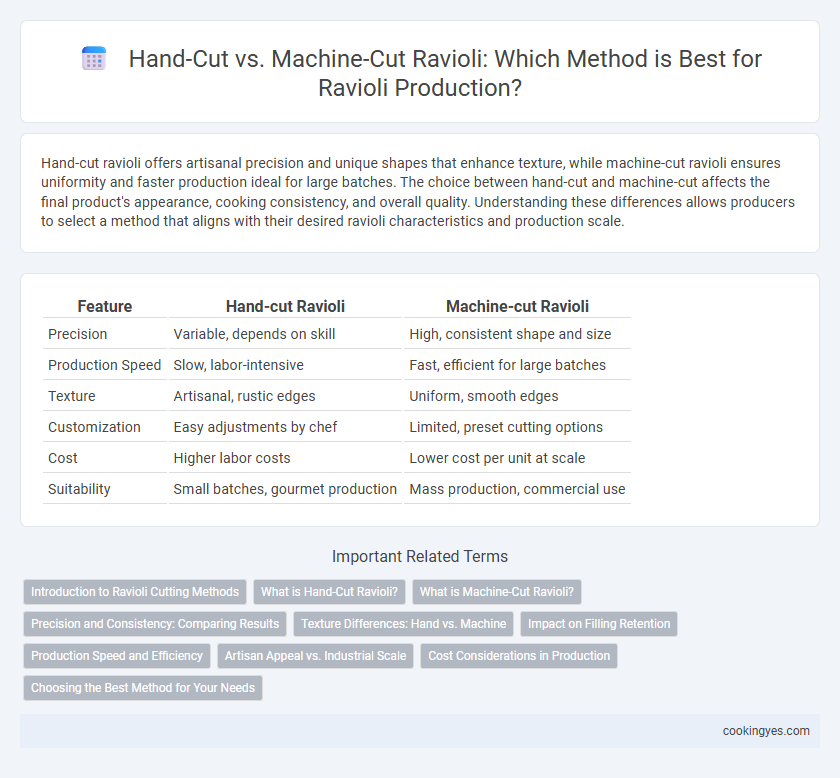

Table of Comparison

| Feature | Hand-cut Ravioli | Machine-cut Ravioli |

|---|---|---|

| Precision | Variable, depends on skill | High, consistent shape and size |

| Production Speed | Slow, labor-intensive | Fast, efficient for large batches |

| Texture | Artisanal, rustic edges | Uniform, smooth edges |

| Customization | Easy adjustments by chef | Limited, preset cutting options |

| Cost | Higher labor costs | Lower cost per unit at scale |

| Suitability | Small batches, gourmet production | Mass production, commercial use |

Introduction to Ravioli Cutting Methods

Hand-cut ravioli production offers artisanal precision and irregular shapes, enhancing texture and flavor distribution, while machine-cut methods ensure uniform size and higher efficiency in mass production. The choice between hand-cut and machine-cut impacts dough consistency, filling placement accuracy, and overall product quality. Understanding these cutting methods is essential for optimizing ravioli texture, presentation, and production scalability.

What is Hand-Cut Ravioli?

Hand-cut ravioli are crafted by manually cutting dough sheets into individual pieces, offering artisanal precision and unique shapes compared to uniform machine-cut counterparts. This traditional method allows control over thickness and filling distribution, enhancing texture and flavor authenticity. Hand-cut ravioli often feature rustic edges and variations that highlight craftsmanship, preferred in gourmet and small-batch productions.

What is Machine-Cut Ravioli?

Machine-cut ravioli refers to pasta pieces shaped and sealed using industrial equipment that ensures uniform size and consistent edges. This method increases production speed and standardizes portion control, making it ideal for large-scale manufacturing. Machine-cut ravioli often features precisely sealed seams that help retain filling and prevent leakage during cooking.

Precision and Consistency: Comparing Results

Hand-cut ravioli allows for artisanal precision with unique variations in shape and size, showcasing craftsmanship but often resulting in minor inconsistencies. Machine-cut ravioli delivers uniform edges and consistent dimensions across large batches, enhancing cooking evenness and presentation quality. Precision in machine-cut ravioli promotes efficiency in commercial production, while hand-cut methods prioritize traditional aesthetics and texture variations.

Texture Differences: Hand vs. Machine

Hand-cut ravioli typically exhibit a more artisanal texture with slightly uneven edges that enhance sauce adherence and provide a rustic bite. Machine-cut ravioli offer uniform thickness and precise shapes, resulting in consistent cooking times but a smoother, less varied texture. The subtle inconsistencies in hand-cut ravioli contribute to a traditional mouthfeel favored in gourmet preparations.

Impact on Filling Retention

Hand-cut ravioli typically offers superior filling retention due to the precise control over dough thickness and edges, minimizing leaks during cooking. Machine-cut ravioli may experience higher filling spillage as automated cutters often create thinner seams that are prone to opening under heat. Maintaining optimal dough thickness and properly sealing edges are critical factors in preserving filling integrity regardless of cutting method.

Production Speed and Efficiency

Hand-cut ravioli offers artisanal precision but significantly slower production speeds compared to machine-cut methods, which can produce thousands of pieces per hour with consistent size and shape. Machine-cut ravioli enhances efficiency by reducing labor costs and minimizing dough waste through automated, precise cutting mechanisms. For large-scale production, machine-cutting is preferred to maximize output and maintain uniform quality, while hand-cutting suits small-batch, gourmet ravioli makers emphasizing craftsmanship.

Artisan Appeal vs. Industrial Scale

Hand-cut ravioli embody an artisan appeal, offering unique, irregular shapes that highlight craftsmanship and traditional techniques, often favored by gourmet kitchens and small-scale producers. Machine-cut ravioli ensure uniformity and consistency, optimizing production speed and volume for industrial-scale operations while maintaining quality through precise cutting mechanisms. Balancing artisan aesthetics with mass production demands, the choice between hand-cut and machine-cut methods reflects priorities in authenticity versus efficiency.

Cost Considerations in Production

Hand-cut ravioli production involves higher labor costs due to the time-intensive manual process, making it less cost-efficient for large-scale manufacturing. Machine-cut ravioli significantly reduces labor expenses by automating cutting, increasing output while maintaining consistent shapes and sizes. Investing in machinery entails upfront capital costs but results in lower per-unit production costs and improved scalability over time.

Choosing the Best Method for Your Needs

Hand-cut ravioli offers artisanal texture and unique shapes, ideal for small-batch, customized production with a focus on craftsmanship. Machine-cut ravioli provides consistent size and shape, efficient high-volume output, and reduced labor costs, suitable for commercial-scale operations. Evaluating production scale, quality requirements, and budget helps determine the best cutting method for optimal ravioli manufacturing.

Hand-cut vs Machine-cut for ravioli production Infographic

cookingyes.com

cookingyes.com