Wet batch popping involves soaking popcorn kernels in water before heating, which helps retain moisture and creates a tender, fluffy texture when popped. Dry batch popping uses kernels at their natural moisture levels, resulting in a crunchier, sometimes slightly tougher bite. Choosing between wet and dry batch methods depends on preferred popcorn texture and popping consistency.

Table of Comparison

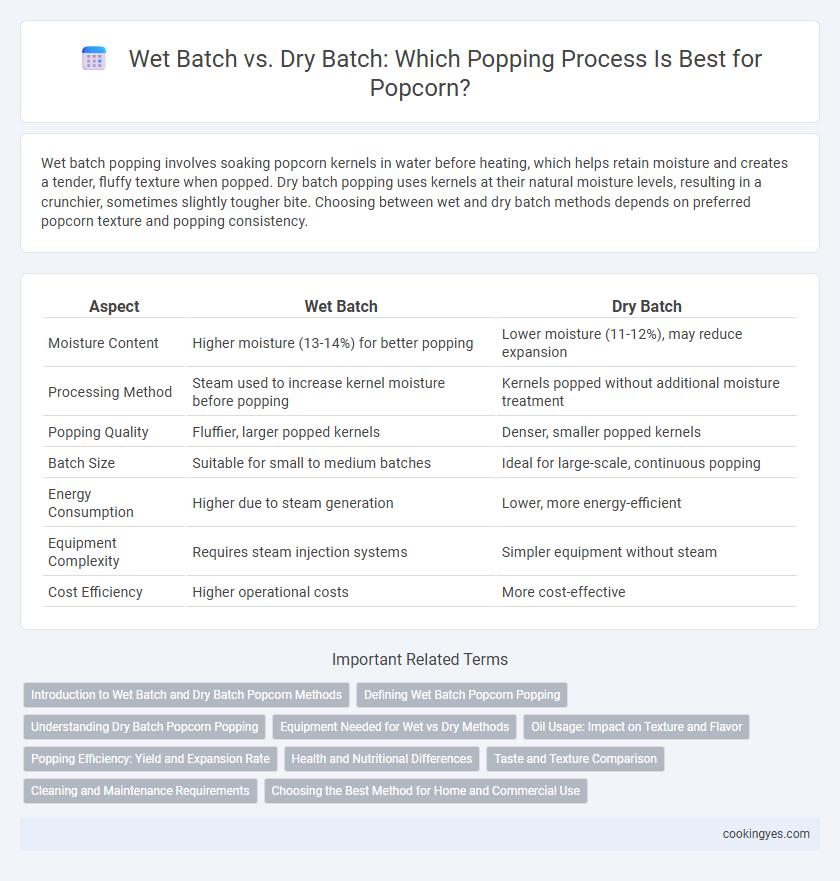

| Aspect | Wet Batch | Dry Batch |

|---|---|---|

| Moisture Content | Higher moisture (13-14%) for better popping | Lower moisture (11-12%), may reduce expansion |

| Processing Method | Steam used to increase kernel moisture before popping | Kernels popped without additional moisture treatment |

| Popping Quality | Fluffier, larger popped kernels | Denser, smaller popped kernels |

| Batch Size | Suitable for small to medium batches | Ideal for large-scale, continuous popping |

| Energy Consumption | Higher due to steam generation | Lower, more energy-efficient |

| Equipment Complexity | Requires steam injection systems | Simpler equipment without steam |

| Cost Efficiency | Higher operational costs | More cost-effective |

Introduction to Wet Batch and Dry Batch Popcorn Methods

Wet batch popcorn involves adding a small amount of water to the kernels before popping, enhancing moisture content and enabling more consistent expansion for fluffier results. Dry batch popcorn relies solely on the inherent moisture within kernels, often producing a drier, crunchier texture but requiring precise heat control to prevent burning. Understanding these methods helps optimize popping efficiency and tailor texture preferences based on moisture retention and heat distribution.

Defining Wet Batch Popcorn Popping

Wet batch popcorn popping involves adding a precise amount of moisture to popcorn kernels before heating, enhancing expansion and creating tender, evenly popped kernels. This method relies on the water content inside the kernels turning into steam during heating, which exerts pressure until the hull bursts, releasing the starchy interior. Compared to dry batch popping, wet batch processes improve kernel consistency, reduce unpopped kernels, and deliver superior texture and flavor.

Understanding Dry Batch Popcorn Popping

Dry batch popcorn popping involves using kernels with minimal moisture content, resulting in a more consistent and controlled expansion during the heating process. This method reduces the risk of uneven popping and burnt kernels by maintaining an optimal moisture level around 13-14%, which is crucial for ideal kernel explosion. Dry batch popping yields a crispier texture and better shelf stability compared to wet batch methods, making it preferred in commercial popcorn production.

Equipment Needed for Wet vs Dry Methods

Wet batch popping requires equipment capable of handling moisture-rich kernels, such as steam injectors or moisture-controlled poppers to maintain optimal humidity levels for consistent popping. Dry batch popping uses traditional hot-air or oil-based poppers designed to operate without added steam, requiring less complex machinery and simpler temperature controls. Choosing between wet and dry batch methods influences equipment investment, with wet batch systems often demanding more advanced, moisture regulation technology.

Oil Usage: Impact on Texture and Flavor

Wet batch popcorn popping involves pre-soaking kernels with oil, resulting in a richer flavor and a slightly crispier texture due to even oil distribution. Dry batch popping uses minimal or no added oil, producing a lighter, crunchier popcorn that highlights the kernels' natural taste. The choice between wet and dry batch directly affects oil absorption, which in turn influences both the mouthfeel and overall flavor profile of the popcorn.

Popping Efficiency: Yield and Expansion Rate

Wet batch popcorn contains kernels with higher moisture content, resulting in increased popping yield and larger expansion volumes due to better steam generation inside the kernel. Dry batch popcorn, with lower moisture levels, tends to have lower popping efficiency and reduced expansion, producing fewer fully popped kernels. Optimizing moisture content in wet batch processing directly enhances both the yield percentage and the expansion rate, leading to superior popcorn quality and volume.

Health and Nutritional Differences

Wet batch popping involves adding oil or water to kernels before heat application, potentially increasing calorie and fat content, while dry batch popping uses hot air, minimizing added fats and preserving the popcorn's low-calorie profile. Wet batch popcorn can retain more moisture, resulting in a softer texture but may introduce additional saturated fats depending on the oil used, affecting heart health. Dry batch methods promote a lighter snack option rich in fiber and antioxidants with fewer calories and no added oils, making it preferable for weight management and overall nutritional benefits.

Taste and Texture Comparison

Wet batch popcorn retains moisture during popping, resulting in a tender, chewy texture and a richer, more buttery flavor profile. Dry batch popcorn pops with less moisture, producing a crispier, crunchier texture and a lighter taste that highlights the natural corn sweetness. Preference between wet and dry batch often depends on desired mouthfeel and flavor intensity, with wet batch favored for moist, flavorful kernels and dry batch preferred for crisp, airy bites.

Cleaning and Maintenance Requirements

Wet batch popping processes require more frequent cleaning due to the use of added oils and moisture, which can cause residue buildup and increase the risk of microbial growth. Dry batch systems, relying solely on heat without added liquids, typically involve less frequent maintenance and simpler cleaning routines, minimizing downtime. Proper cleaning protocols for both methods are essential to ensure food safety and maintain optimal popping performance.

Choosing the Best Method for Home and Commercial Use

Wet batch popcorn involves soaking kernels in water before popping, resulting in more consistent moisture content and uniform popping, ideal for commercial use where quality control is crucial. Dry batch popping, which uses unsoaked kernels, offers faster preparation and is preferred for home use due to its simplicity and minimal equipment requirements. Selecting the best method depends on balancing the need for consistent popcorn quality and production speed against ease of use and intended volume.

Wet Batch vs Dry Batch for Popping Process Infographic

cookingyes.com

cookingyes.com