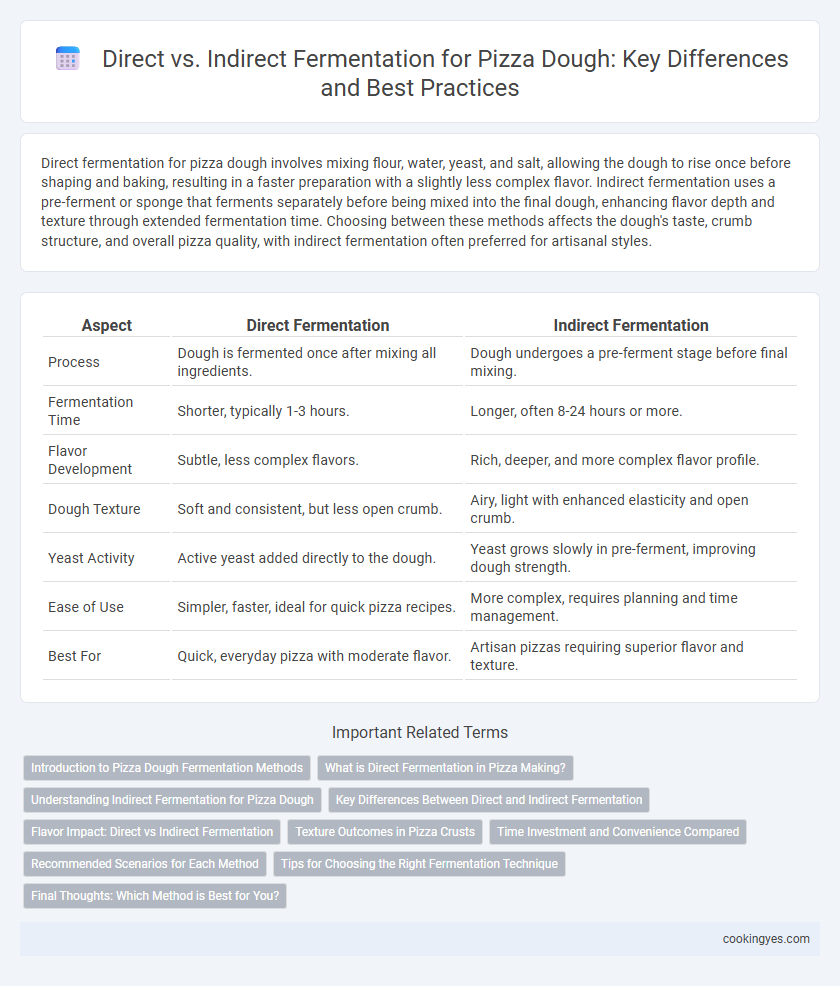

Direct fermentation for pizza dough involves mixing flour, water, yeast, and salt, allowing the dough to rise once before shaping and baking, resulting in a faster preparation with a slightly less complex flavor. Indirect fermentation uses a pre-ferment or sponge that ferments separately before being mixed into the final dough, enhancing flavor depth and texture through extended fermentation time. Choosing between these methods affects the dough's taste, crumb structure, and overall pizza quality, with indirect fermentation often preferred for artisanal styles.

Table of Comparison

| Aspect | Direct Fermentation | Indirect Fermentation |

|---|---|---|

| Process | Dough is fermented once after mixing all ingredients. | Dough undergoes a pre-ferment stage before final mixing. |

| Fermentation Time | Shorter, typically 1-3 hours. | Longer, often 8-24 hours or more. |

| Flavor Development | Subtle, less complex flavors. | Rich, deeper, and more complex flavor profile. |

| Dough Texture | Soft and consistent, but less open crumb. | Airy, light with enhanced elasticity and open crumb. |

| Yeast Activity | Active yeast added directly to the dough. | Yeast grows slowly in pre-ferment, improving dough strength. |

| Ease of Use | Simpler, faster, ideal for quick pizza recipes. | More complex, requires planning and time management. |

| Best For | Quick, everyday pizza with moderate flavor. | Artisan pizzas requiring superior flavor and texture. |

Introduction to Pizza Dough Fermentation Methods

Direct fermentation for pizza dough involves mixing all ingredients and allowing the dough to ferment in a single step, resulting in faster preparation and a simpler process ideal for quick pizza production. Indirect fermentation uses a pre-ferment like a poolish or biga, enhancing flavor complexity, dough strength, and texture through extended fermentation times. Choosing the appropriate method impacts the dough's rise, taste profile, and overall pizza quality, making fermentation a critical factor in artisanal pizza craftsmanship.

What is Direct Fermentation in Pizza Making?

Direct fermentation in pizza making involves mixing all ingredients--flour, water, yeast, salt, and sometimes sugar--at once, allowing the dough to ferment continuously until fully risen and ready for shaping. This method accelerates dough development, producing a pizza crust with a softer texture and less complex flavor compared to indirect or slow fermentation techniques. Direct fermentation is ideal for quick dough preparation but may sacrifice some depth in taste and aroma often achieved with extended fermentation.

Understanding Indirect Fermentation for Pizza Dough

Indirect fermentation for pizza dough involves an initial fermentation stage where a preferment, such as a poolish or biga, is created by mixing a portion of flour, water, and yeast, allowing it to ferment slowly before combining with the remaining ingredients. This method enhances flavor complexity and dough texture by developing organic acids and alcohol during the extended fermentation period, resulting in a crust with improved aroma and chewiness. Professional pizzerias often prefer indirect fermentation because it provides greater control over dough characteristics and extends shelf life compared to the direct fermentation process.

Key Differences Between Direct and Indirect Fermentation

Direct fermentation involves mixing all ingredients at once and allowing the dough to ferment in a single stage, resulting in a faster rise and simpler process ideal for quick pizza preparation. Indirect fermentation uses a preferment or sponge, where part of the flour and water ferments separately before combining with the remaining ingredients, producing a dough with enhanced flavor complexity and improved texture. The key differences lie in fermentation time, flavor development, and dough handling, with indirect fermentation offering superior taste and extensibility at the cost of longer preparation.

Flavor Impact: Direct vs Indirect Fermentation

Direct fermentation creates a pizza dough with a straightforward, yeasty flavor due to the shorter fermentation time, resulting in less complex taste profiles. Indirect fermentation involves a longer, slower process with pre-ferments like biga or poolish, enhancing the dough's flavor through the development of organic acids and alcohols, producing richer, more nuanced aromas. This extended fermentation also improves dough texture and crust color while offering a more pronounced tanginess characteristic of artisanal pizzas.

Texture Outcomes in Pizza Crusts

Direct fermentation in pizza dough results in a chewier and denser crust due to the shorter fermentation time limiting gluten development and gas retention. Indirect fermentation, often involving a pre-ferment or cold fermentation, enhances dough extensibility and creates a lighter, airier pizza crust with more complex flavor profiles. Texture outcomes in pizza crusts are significantly influenced by fermentation method, with indirect fermentation producing a more open crumb structure and crispier edges.

Time Investment and Convenience Compared

Direct fermentation for pizza dough requires less time investment, typically a few hours to rise, making it convenient for quick preparation. Indirect fermentation involves a longer process with a pre-ferment or starter, enhancing flavor complexity but demanding more planning and patience. Choosing between the two depends on the balance between time availability and desired dough characteristics in pizza making.

Recommended Scenarios for Each Method

Direct fermentation is recommended for pizza dough when a quick turnaround is necessary, such as in pizzerias with high daily demand or when same-day preparation is preferred. Indirect fermentation suits artisan or Neapolitan-style pizzas requiring enhanced flavor complexity and improved dough texture through extended cold fermentation, often lasting 24 to 72 hours. Home bakers and specialty pizza makers benefit from indirect methods to develop deep, aromatic profiles that elevate the final product's quality.

Tips for Choosing the Right Fermentation Technique

Selecting the right fermentation technique for pizza dough depends on factors like desired flavor complexity, dough handling time, and kitchen workflow. Direct fermentation, with its faster rise using fresh yeast, suits quick preparation and yields a mild, soft crust, while indirect fermentation involves a cold ferment or preferment that enhances flavor development and texture over extended hours. Consider fermentation time, temperature control, and your pizza style to optimize dough performance and taste.

Final Thoughts: Which Method is Best for You?

Direct fermentation offers a faster process with a more straightforward approach, producing a softer, more yeasty flavor ideal for quick pizza dough preparation. Indirect fermentation requires longer proofing and the use of a preferment, resulting in enhanced dough flavor, better texture, and improved shelf life, preferred by artisanal pizza makers. Your choice depends on whether speed and simplicity or depth of flavor and texture are your top priorities in pizza dough crafting.

Direct vs Indirect fermentation for pizza dough Infographic

cookingyes.com

cookingyes.com