Handmade noodles offer a unique texture and flavor due to the artisanal techniques involved in their production, often resulting in a chewier and more uneven surface that enhances sauce absorption. Machine-made noodles provide consistency in shape and size, enabling faster production and uniform cooking times essential for large-scale manufacturing. While handmade noodles emphasize craftsmanship and traditional quality, machine-made noodles prioritize efficiency and scalability in the noodle pet industry.

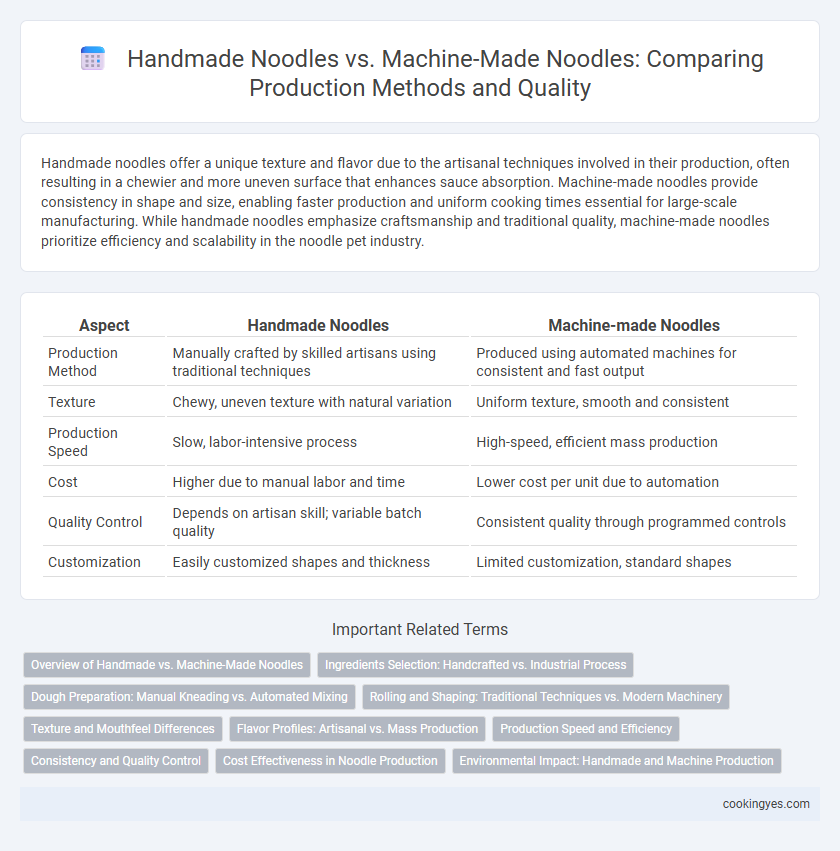

Table of Comparison

| Aspect | Handmade Noodles | Machine-made Noodles |

|---|---|---|

| Production Method | Manually crafted by skilled artisans using traditional techniques | Produced using automated machines for consistent and fast output |

| Texture | Chewy, uneven texture with natural variation | Uniform texture, smooth and consistent |

| Production Speed | Slow, labor-intensive process | High-speed, efficient mass production |

| Cost | Higher due to manual labor and time | Lower cost per unit due to automation |

| Quality Control | Depends on artisan skill; variable batch quality | Consistent quality through programmed controls |

| Customization | Easily customized shapes and thickness | Limited customization, standard shapes |

Overview of Handmade vs. Machine-Made Noodles

Handmade noodles exhibit a unique texture and flavor due to the artisanal kneading and cutting processes, resulting in varied thickness and elasticity that enhance culinary experience. Machine-made noodles offer consistent shape, size, and texture, enabling large-scale production with greater efficiency and reduced labor costs. The choice between handmade and machine-made noodles impacts product quality, production speed, and scalability in the noodle industry.

Ingredients Selection: Handcrafted vs. Industrial Process

Handmade noodles often use carefully selected, high-quality ingredients like premium wheat flour and fresh eggs to enhance texture and flavor, reflecting artisanal craftsmanship in each batch. Machine-made noodles typically rely on standardized ingredient blends and preservatives to ensure consistent quality and extended shelf life in large-scale production. The ingredient selection in handmade noodles prioritizes natural components, whereas industrial processes emphasize efficiency and uniformity through controlled formulations.

Dough Preparation: Manual Kneading vs. Automated Mixing

Handmade noodles involve manual kneading, which allows for precise control over dough texture and elasticity, resulting in a unique, artisanal quality favored in traditional cuisines. Machine-made noodles utilize automated mixing, ensuring consistent dough hydration and uniformity, which enhances production efficiency and scalability. Both methods impact the gluten network development differently, influencing noodle firmness and cooking performance.

Rolling and Shaping: Traditional Techniques vs. Modern Machinery

Handmade noodles rely on artisanal rolling and shaping techniques that create unique textures and irregularities, enhancing the noodles' bite and mouthfeel. In contrast, modern machinery utilizes precise rollers and cutters to produce uniform thickness and consistent shapes, optimizing speed and scalability in production. The combination of traditional craftsmanship and advanced technology impacts the final noodle quality and production efficiency.

Texture and Mouthfeel Differences

Handmade noodles offer a chewier, more irregular texture due to the artisanal kneading and stretching processes that create variable thickness and air pockets. Machine-made noodles provide a consistent, uniform texture but often lack the elasticity and nuanced mouthfeel found in handmade varieties. The production method directly influences gluten development, with handmade techniques enhancing a springier bite compared to the denser, more homogeneous texture of machine-made noodles.

Flavor Profiles: Artisanal vs. Mass Production

Handmade noodles offer a richer, more textured flavor profile due to the artisanal techniques that preserve gluten structure and allow better sauce absorption. Machine-made noodles tend to have a uniform texture but lack the nuanced bite and complex taste that come from hand-kneading and slower drying processes. Artisanal production emphasizes quality and distinct flavor, contrasting with the efficiency and consistency prioritized in mass production.

Production Speed and Efficiency

Handmade noodles require skilled labor and longer preparation time, resulting in lower production speed and efficiency compared to machine-made noodles. Machine-made noodles utilize automated processes that can produce large quantities rapidly, ensuring consistent quality and reducing labor costs. High-speed noodle production lines enhance efficiency by minimizing downtime and maximizing output, making them ideal for mass-market demands.

Consistency and Quality Control

Handmade noodles provide a unique texture and flavor due to skilled craftsmanship but often face variability in size and thickness, impacting consistency. Machine-made noodles ensure uniformity in shape and cooking time, enhancing quality control for large-scale production. Standardized processes in machine manufacturing minimize human error, resulting in consistent product quality across batches.

Cost Effectiveness in Noodle Production

Handmade noodles require significantly more labor and time, increasing production costs compared to machine-made noodles, which benefit from automation and speed. Machine-made noodles consistently reduce expenses by enabling large-scale output with minimal human intervention, optimizing cost-effectiveness in mass production. Despite higher initial equipment investments, the efficiency and uniformity of machine-made noodles make them the preferred choice for cost-conscious noodle manufacturers.

Environmental Impact: Handmade and Machine Production

Handmade noodles generate less carbon emissions due to minimal energy consumption compared to highly mechanized production lines. Machine-made noodles, while efficient in mass production, rely on electricity and industrial equipment that increase the environmental footprint. Sustainable noodle production favors handmade methods for their lower resource usage and waste output.

Handmade noodles vs Machine-made noodles for production method Infographic

cookingyes.com

cookingyes.com