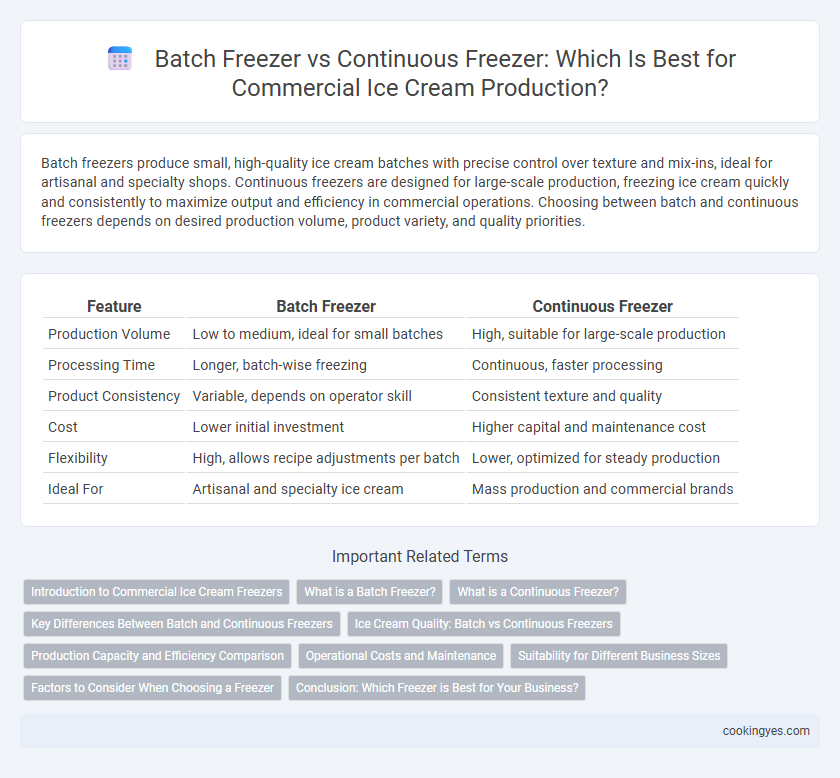

Batch freezers produce small, high-quality ice cream batches with precise control over texture and mix-ins, ideal for artisanal and specialty shops. Continuous freezers are designed for large-scale production, freezing ice cream quickly and consistently to maximize output and efficiency in commercial operations. Choosing between batch and continuous freezers depends on desired production volume, product variety, and quality priorities.

Table of Comparison

| Feature | Batch Freezer | Continuous Freezer |

|---|---|---|

| Production Volume | Low to medium, ideal for small batches | High, suitable for large-scale production |

| Processing Time | Longer, batch-wise freezing | Continuous, faster processing |

| Product Consistency | Variable, depends on operator skill | Consistent texture and quality |

| Cost | Lower initial investment | Higher capital and maintenance cost |

| Flexibility | High, allows recipe adjustments per batch | Lower, optimized for steady production |

| Ideal For | Artisanal and specialty ice cream | Mass production and commercial brands |

Introduction to Commercial Ice Cream Freezers

Batch freezers produce small, consistent quantities of ice cream by freezing and churning mixtures in cycles, ideal for artisanal or small-scale production. Continuous freezers operate non-stop, efficiently producing large volumes by freezing the mix while simultaneously incorporating air, making them suited for mass commercial production. The choice between batch and continuous freezers impacts ice cream texture, production speed, and scalability in commercial operations.

What is a Batch Freezer?

A batch freezer is a commercial ice cream machine designed to freeze and aerate a specific quantity of mix in discrete batches, ensuring precise control over texture and overrun. It operates by freezing the mix around a rotating dasher inside a refrigerated cylinder, allowing customization for small to medium-scale production. This method produces high-quality ice cream with consistent texture and flavor, ideal for artisanal or specialty ice cream businesses.

What is a Continuous Freezer?

A Continuous Freezer is a commercial ice cream machine designed to produce large quantities of ice cream by continuously freezing and simultaneously aerating the mix, ensuring consistent texture and quality. Unlike batch freezers, which operate in discrete cycles, continuous freezers keep the ice cream mix flowing through the freezing chamber, allowing for efficient, high-volume production. This equipment is essential for industrial-scale ice cream manufacturers seeking rapid output with precise control over overrun and viscosity.

Key Differences Between Batch and Continuous Freezers

Batch freezers produce ice cream in discrete quantities, allowing for greater control over texture and ingredient variations, making them ideal for small to medium-scale production. Continuous freezers operate non-stop, efficiently producing large volumes with consistent quality by continuously freezing and incorporating air, suitable for mass production. Key differences include batch freezers offering flexibility and better customization, while continuous freezers maximize output and operational efficiency.

Ice Cream Quality: Batch vs Continuous Freezers

Batch freezers produce ice cream with a creamier texture and superior flavor retention due to slower freezing and enhanced air incorporation, making them ideal for premium, small-batch products. Continuous freezers operate at higher speeds, enabling large-scale production but often result in a denser texture with less control over overrun and flavor intensity. Commercial ice cream manufacturers prioritize batch freezers for artisanal quality, while continuous freezers suit high-volume operations demanding consistency and efficiency.

Production Capacity and Efficiency Comparison

Batch freezers produce smaller quantities of ice cream per cycle, typically ranging from 5 to 50 liters, catering to artisanal and small-scale production with greater control over texture. Continuous freezers enable high-volume commercial output, processing hundreds to thousands of liters per hour, significantly increasing production capacity and reducing labor costs. Efficiency of continuous freezers stems from their ability to maintain consistent product quality while minimizing energy consumption and downtime.

Operational Costs and Maintenance

Batch freezers generally incur higher operational costs and maintenance due to frequent cleaning cycles and labor-intensive manual intervention, but they offer flexibility for small-scale production. Continuous freezers provide lower operational expenses with automated processes and streamlined maintenance schedules, optimizing energy usage and minimizing downtime in large-scale commercial ice cream manufacturing. Selecting the appropriate freezer depends on production volume, with continuous freezers favored for high-output facilities seeking efficiency and batch freezers suited for artisanal or specialty ice cream operations.

Suitability for Different Business Sizes

Batch freezers excel in small to medium-sized ice cream businesses, offering flexibility and precise control ideal for artisanal production and limited runs. Continuous freezers cater to large-scale commercial operations requiring high-volume output and consistent product texture with minimal manual intervention. Choosing between batch and continuous freezers depends on production capacity, product variety, and automation needs specific to business scale.

Factors to Consider When Choosing a Freezer

Batch freezers offer precise control over ice cream texture and flavor, making them ideal for small to medium-scale production with frequent recipe changes. Continuous freezers provide higher output and efficiency, suitable for large-scale commercial operations demanding consistent volume and uniform product quality. When choosing between them, consider production capacity, desired product variety, budget constraints, and available space to optimize operational efficiency and product consistency.

Conclusion: Which Freezer is Best for Your Business?

Batch freezers offer greater flexibility and are ideal for small to medium-sized commercial ice cream producers seeking varied flavors and artisanal quality. Continuous freezers excel in high-volume production with consistent texture and efficiency, making them suitable for large-scale operations. Choosing the best freezer depends on your business scale, flavor diversity needs, and production speed requirements.

Batch freezer vs Continuous freezer for commercial ice cream Infographic

cookingyes.com

cookingyes.com