Hand rolling croissant dough allows for meticulous control over the thickness and layering, resulting in a flakier and more delicate pastry. In contrast, a sheeter machine streamlines the lamination process, ensuring uniform layers and saving time, especially in large-scale production. While hand rolling suits artisanal croissant making, sheeter machines enhance consistency and efficiency in commercial settings.

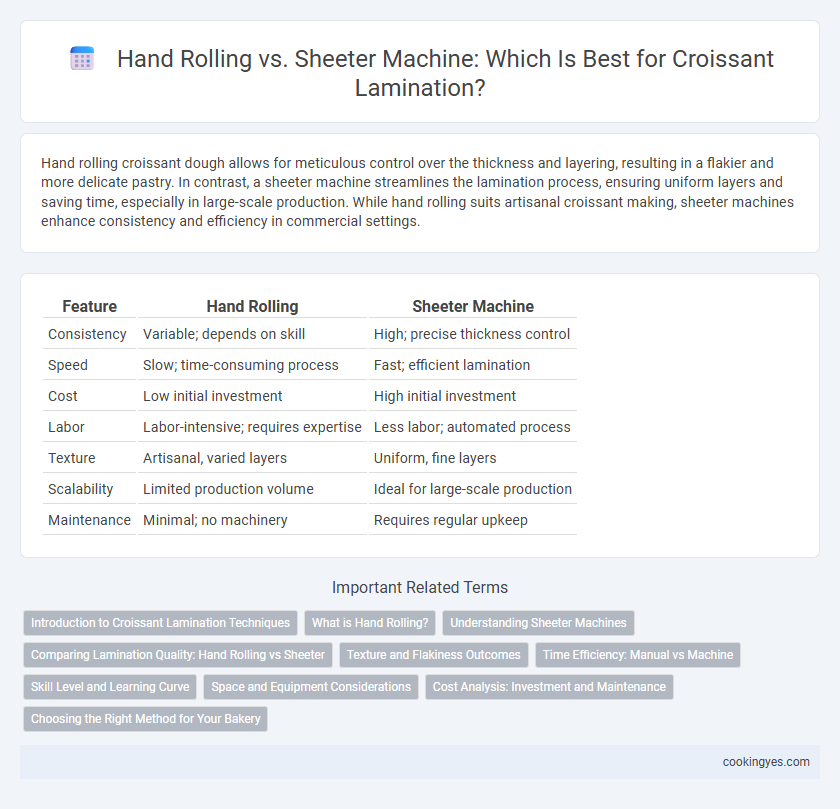

Table of Comparison

| Feature | Hand Rolling | Sheeter Machine |

|---|---|---|

| Consistency | Variable; depends on skill | High; precise thickness control |

| Speed | Slow; time-consuming process | Fast; efficient lamination |

| Cost | Low initial investment | High initial investment |

| Labor | Labor-intensive; requires expertise | Less labor; automated process |

| Texture | Artisanal, varied layers | Uniform, fine layers |

| Scalability | Limited production volume | Ideal for large-scale production |

| Maintenance | Minimal; no machinery | Requires regular upkeep |

Introduction to Croissant Lamination Techniques

Hand rolling croissant dough offers artisanal control over butter distribution and layer thickness, enhancing flakiness and texture through manual precision. Sheeter machines improve efficiency and consistency by uniformly flattening dough and butter layers, enabling higher production volumes with reduced labor. Choosing between these techniques depends on balancing craftsmanship with scalability in croissant lamination processes.

What is Hand Rolling?

Hand rolling in croissant lamination involves manually folding and rolling the dough to create thin, even layers of butter and dough, essential for a flaky texture. This traditional technique allows bakers to control pressure and thickness precisely, resulting in superior flakiness and a handcrafted appearance. Hand rolling requires skill and time but enhances the croissant's delicate crumb and buttery flavor.

Understanding Sheeter Machines

Sheeter machines are essential for croissant lamination, offering consistent dough thickness and uniform layer formation that enhances the flaky texture. Unlike hand rolling, sheeter machines increase production efficiency by reducing manual labor and minimizing dough temperature variations during lamination. Their precise control over dough elasticity and thickness ensures optimal butter distribution, crucial for high-quality croissant layers.

Comparing Lamination Quality: Hand Rolling vs Sheeter

Hand rolling croissant dough produces more distinct, flaky layers with varied thicknesses, contributing to a traditionally artisanal texture. Sheeter machines ensure consistent lamination by evenly flattening dough, resulting in uniform layers and precise butter distribution for mass production. While hand rolling enhances unique flakiness and character, sheeters optimize efficiency and consistency in croissant lamination quality.

Texture and Flakiness Outcomes

Hand rolling croissant dough produces a more irregular, artisan texture with pronounced layers, enhancing flakiness due to varied pressure and folding. Sheeter machines ensure consistent dough thickness and uniform lamination, resulting in evenly spaced layers but a slightly denser crumb. Bakers aiming for a delicate, flaky croissant often prefer hand rolling, while commercial production favors sheeter machines for efficiency and uniformity.

Time Efficiency: Manual vs Machine

Hand rolling croissant dough requires significant time and skilled labor, often taking up to 30 minutes per batch for proper lamination. Sheeter machines drastically reduce lamination time, processing dough sheets in under 5 minutes while ensuring consistent thickness and layers. Machine lamination optimizes time efficiency, increases production capacity, and maintains quality control in commercial bakery settings.

Skill Level and Learning Curve

Hand rolling croissants demands advanced craftsmanship, requiring precise control over dough thickness and butter distribution, reflecting a steep learning curve suitable for skilled bakers. Sheeter machines streamline lamination by consistently applying pressure and fold patterns, significantly reducing manual effort and accelerating the learning process for beginners. Mastery of hand rolling enhances artisanal quality, while sheeters optimize efficiency and scalability in croissant production.

Space and Equipment Considerations

Hand rolling croissant dough requires minimal equipment, making it ideal for small kitchens with limited space, as only a rolling pin and flat surface are essential. Sheeter machines demand a dedicated area due to their size and require electrical power, increasing the need for space allocation and maintenance. Choosing between hand rolling and a sheeter machine depends on available kitchen space, production volume, and investment capacity for equipment.

Cost Analysis: Investment and Maintenance

Hand rolling croissants demands higher labor costs and longer production times, significantly increasing overall expenses compared to sheeter machines. Sheeter machines require substantial upfront investment but reduce labor costs and ensure consistent lamination, offering better long-term cost efficiency. Maintenance for sheeter machines involves periodic servicing and potential part replacements, whereas hand rolling incurs minimal equipment maintenance but higher ongoing labor expenditures.

Choosing the Right Method for Your Bakery

Hand rolling croissants allows bakers to achieve precise control over dough thickness and layering, enhancing the flakiness and texture favored in artisanal bakeries. Sheeter machines increase efficiency and consistency, enabling higher production volumes while maintaining uniform lamination quality crucial for commercial bakeries. Selecting between hand rolling and a sheeter machine depends on your bakery's scale, desired product authenticity, and production capacity demands.

Hand rolling vs sheeter machine for croissant lamination Infographic

cookingyes.com

cookingyes.com