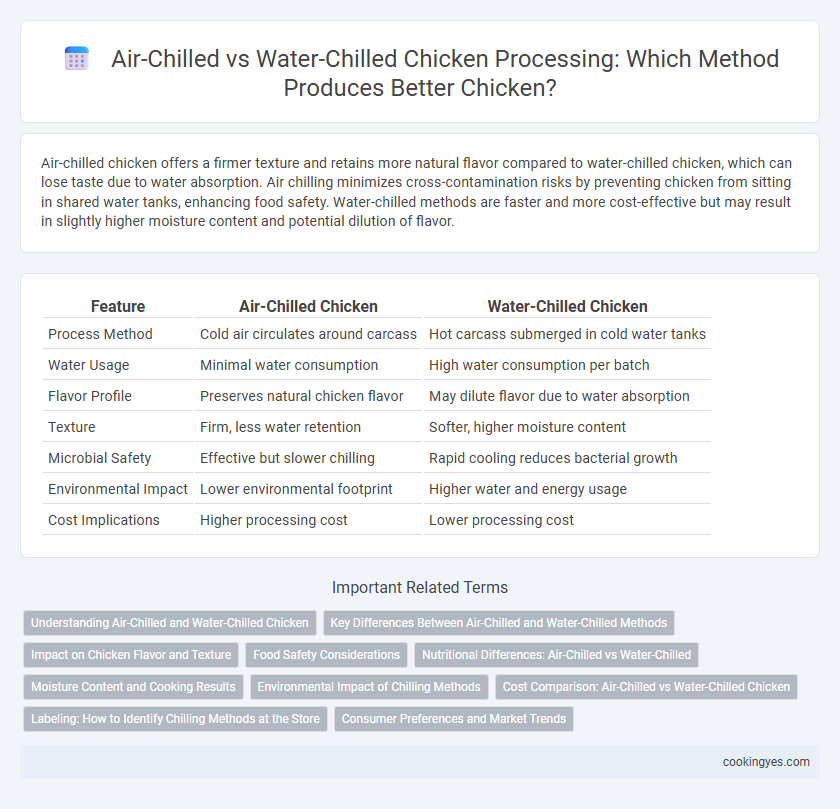

Air-chilled chicken offers a firmer texture and retains more natural flavor compared to water-chilled chicken, which can lose taste due to water absorption. Air chilling minimizes cross-contamination risks by preventing chicken from sitting in shared water tanks, enhancing food safety. Water-chilled methods are faster and more cost-effective but may result in slightly higher moisture content and potential dilution of flavor.

Table of Comparison

| Feature | Air-Chilled Chicken | Water-Chilled Chicken |

|---|---|---|

| Process Method | Cold air circulates around carcass | Hot carcass submerged in cold water tanks |

| Water Usage | Minimal water consumption | High water consumption per batch |

| Flavor Profile | Preserves natural chicken flavor | May dilute flavor due to water absorption |

| Texture | Firm, less water retention | Softer, higher moisture content |

| Microbial Safety | Effective but slower chilling | Rapid cooling reduces bacterial growth |

| Environmental Impact | Lower environmental footprint | Higher water and energy usage |

| Cost Implications | Higher processing cost | Lower processing cost |

Understanding Air-Chilled and Water-Chilled Chicken

Air-chilled chicken undergoes a cooling process where chilled air circulates around each bird, minimizing water retention and preserving natural flavor and texture. Water-chilled chicken is immersed in cold water baths to rapidly reduce temperature, which may increase moisture content but can lead to water absorption and potential flavor dilution. Understanding these methods helps consumers choose between air-chilled chicken's firmer texture and enhanced taste versus water-chilled chicken's typically lower cost and slightly higher yield due to added water weight.

Key Differences Between Air-Chilled and Water-Chilled Methods

Air-chilled chicken undergoes cooling by circulating cold air around the carcasses, resulting in less water retention and firmer texture, while water-chilled chicken is immersed in cold water tanks, which increases moisture uptake but may dilute flavor. The air-chilling process reduces cross-contamination risks by eliminating water reuse, whereas water-chilling requires stringent sanitation to prevent bacterial spread. Air-chilling offers a more natural taste profile and higher product yield retention, making it preferable for premium poultry markets.

Impact on Chicken Flavor and Texture

Air-chilled chicken retains a firmer texture and more natural flavor due to minimal water absorption during processing, preserving the meat's original taste profile. Water-chilled chicken often has a slightly milder flavor and juicier texture, but can absorb excess water, which may dilute the chicken's natural taste. Studies indicate air-chilling is preferred by chefs prioritizing flavor and texture integrity in culinary applications.

Food Safety Considerations

Air-chilled chicken processing reduces cross-contamination risks by avoiding water immersion, which can harbor and spread pathogens like Salmonella and Campylobacter. Water-chilling involves submerging carcasses in chilled water baths, increasing the potential for pathogen transfer between birds if water management is inadequate. Effective sanitation protocols and temperature controls are critical in both methods to ensure microbial safety and comply with food safety regulations.

Nutritional Differences: Air-Chilled vs Water-Chilled

Air-chilled chicken retains more natural flavor and nutrients due to minimal water absorption during processing, resulting in higher protein concentration and less sodium content compared to water-chilled chicken. Water-chilled processing can cause some nutrient dilution as the chicken absorbs water, potentially lowering the levels of vitamins and minerals per serving. Research indicates air-chilled chicken may offer better overall nutrient density, making it a preferred choice for health-conscious consumers.

Moisture Content and Cooking Results

Air-chilled chicken retains lower moisture content compared to water-chilled processing, resulting in firmer texture and more concentrated flavor when cooked. Water-chilled chicken absorbs additional water during processing, leading to higher moisture content that can cause a juicier but less flavorful final product. This difference in moisture content directly impacts cooking results, with air-chilled chicken typically offering better browning and reduced shrinkage.

Environmental Impact of Chilling Methods

Air-chilled chicken processing significantly reduces water consumption compared to water-chilled methods, lowering overall environmental impact. This method prevents cross-contamination and minimizes water pollution by eliminating the need for large volumes of cooling water, which often require extensive treatment before discharge. Energy use and carbon emissions can be higher in air chilling, but advancements in energy-efficient technologies are helping to balance the environmental footprint.

Cost Comparison: Air-Chilled vs Water-Chilled Chicken

Air-chilled chicken processing typically incurs higher operational costs due to increased energy consumption for air circulation and longer processing times compared to water-chilled methods. Water-chilled systems benefit from lower initial investment and reduced energy usage by immersing carcasses in cold water, resulting in faster chilling and cost efficiency. Despite higher upfront expenses, air-chilled chicken often commands premium pricing due to perceived quality advantages, partially offsetting the increased processing costs.

Labeling: How to Identify Chilling Methods at the Store

Air-chilled chicken is typically labeled with terms like "air-chilled" or "cold air chilled," indicating the bird was cooled by circulating cold air around it. Water-chilled chicken may be marked as "water-chilled" or lack specific chilling method labeling but often appears with labels emphasizing moisture retention or quicker cooling. Consumers can identify chilling methods by checking packaging details or seeking certifications related to processing techniques.

Consumer Preferences and Market Trends

Air-chilled chicken retains a firmer texture and more natural flavor, appealing to consumers seeking premium quality and organic options. Water-chilled processing, which uses cold water immersion, tends to be more cost-effective and remains popular in large-scale commercial markets due to its efficiency. Growing consumer demand for sustainably processed, antibiotic-free chicken has driven market trends favoring air-chilled methods in niche and specialty retail segments.

Air-chilled vs Water-chilled for chicken processing Infographic

cookingyes.com

cookingyes.com