Hand-rolling bagels creates a denser texture and allows for unique, artisanal shapes that vary with each batch, emphasizing traditional craftsmanship. Machine-shaping produces uniform bagels with consistent size and shape, increasing production efficiency and meeting high demand. While hand-rolling enhances the texture and authenticity, machine-shaping prioritizes speed and scalability in commercial bakeries.

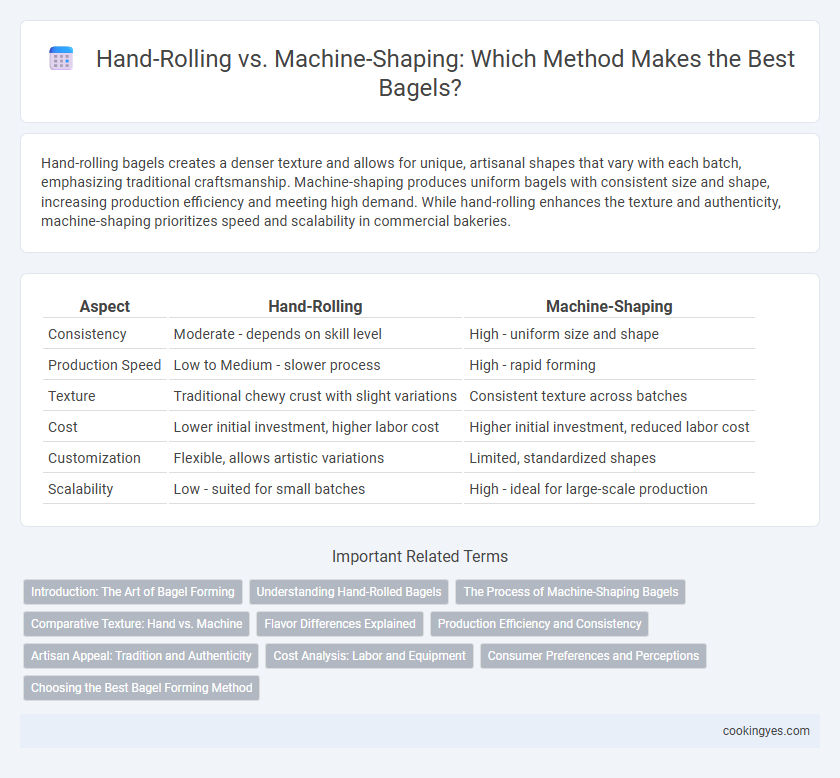

Table of Comparison

| Aspect | Hand-Rolling | Machine-Shaping |

|---|---|---|

| Consistency | Moderate - depends on skill level | High - uniform size and shape |

| Production Speed | Low to Medium - slower process | High - rapid forming |

| Texture | Traditional chewy crust with slight variations | Consistent texture across batches |

| Cost | Lower initial investment, higher labor cost | Higher initial investment, reduced labor cost |

| Customization | Flexible, allows artistic variations | Limited, standardized shapes |

| Scalability | Low - suited for small batches | High - ideal for large-scale production |

Introduction: The Art of Bagel Forming

Hand-rolling bagels creates a denser crumb and allows for artisanal control over shape and texture, appealing to traditional baking methods. Machine-shaping ensures consistent size and uniformity, increasing production efficiency in commercial bakeries. Both techniques influence the final bagel's chewiness and appearance, impacting consumer preference and market demand.

Understanding Hand-Rolled Bagels

Hand-rolled bagels showcase a unique texture and authenticity achieved through skilled manual shaping that allows for a tighter crumb and a chewier bite. This traditional method enhances the bagel's character by creating a thicker outer crust and a more artisanal appearance compared to the uniformity of machine-shaped bagels. Bakers value hand-rolling as it preserves the dough's structure and controls air pockets, contributing to the superior quality and flavor profile of classic New York-style bagels.

The Process of Machine-Shaping Bagels

Machine-shaping bagels involves extruding dough through a mold to create uniform rings rapidly, improving consistency and production speed. This process reduces labor costs and ensures precise control over size and shape, meeting high-volume bakery demands efficiently. Machine-shaped bagels may have a slightly different texture, with a smoother surface compared to the traditional hand-rolled variety.

Comparative Texture: Hand vs. Machine

Hand-rolling bagels creates a denser, chewier texture due to the uneven pressure and natural variations applied by skilled bakers, resulting in a more artisanal crust and crumb. Machine-shaping produces a consistently uniform texture with a slightly lighter and airier crumb, maximizing efficiency but often lacking the rustic character of hand-formed bagels. Texture differences between hand-rolled and machine-shaped bagels significantly influence the overall eating experience, with hand-rolling preferred for traditional authenticity and machine-shaping favored in large-scale production.

Flavor Differences Explained

Hand-rolling bagels creates denser dough pockets, allowing for more complex fermentation and a chewier, richer flavor compared to machine-shaped bagels. Machine-shaping often results in uniform texture with a slightly lighter crumb, but can sacrifice the nuanced tang produced by traditional hand-formed fermentation. The artisanal touch in hand-rolling influences yeast activity and gluten alignment, directly enhancing the depth of taste and authenticity in each bite.

Production Efficiency and Consistency

Hand-rolling bagels offers artisan quality and unique texture but often results in slower production rates and variable shapes, impacting overall consistency. Machine-shaping significantly boosts production efficiency by standardizing size and shape, ensuring uniformity across large batches. The choice between methods depends on balancing desired craftsmanship with scalable output demands.

Artisan Appeal: Tradition and Authenticity

Hand-rolling bagels preserves the artisan appeal by emphasizing tradition and authenticity through a tactile, hands-on process that highlights individual craftsmanship. This method creates unique irregularities and a denser chew, appealing to consumers seeking genuine, time-honored flavors. Machine-shaping, while efficient and consistent, lacks the nuanced texture and personal touch that define traditional bagel-making heritage.

Cost Analysis: Labor and Equipment

Hand-rolling bagels requires higher labor costs due to skilled manual work and slower production rates, impacting overall profitability. Machine-shaping reduces labor expenses by automating the forming process, enabling faster output and consistent quality, but involves significant initial equipment investment and maintenance costs. Balancing these factors depends on production scale, with hand-rolling favored for artisanal bakeries and machine-shaping optimal for high-volume commercial operations.

Consumer Preferences and Perceptions

Hand-rolled bagels are often perceived by consumers as more authentic and artisanal, contributing to a premium product image that emphasizes craftsmanship and tradition. In contrast, machine-shaped bagels typically appeal to those prioritizing consistency and affordability, as automated processes ensure uniformity and faster production times. Consumer preference trends indicate a growing demand for hand-rolled bagels in specialty bakeries, reflecting a desire for unique texture and flavor profiles that machines sometimes fail to replicate.

Choosing the Best Bagel Forming Method

Hand-rolling bagels offers artisanal quality with customizable texture and authentic chewiness, while machine-shaping ensures consistent size and shape, enhancing production efficiency for commercial bakeries. Selecting the best bagel forming method depends on balancing desired product authenticity with scale of production and cost-effectiveness. Bakeries prioritizing traditional flavor may favor hand-rolling, whereas high-volume operations benefit from the uniformity and speed of machine-shaping.

Hand-rolling vs machine-shaping for bagel forming Infographic

cookingyes.com

cookingyes.com