Using a floured surface at the schnitzel breading station helps the coating adhere better by providing a dry base that prevents excess moisture from causing sogginess. A plain surface, in contrast, may allow the breading to slip off or become uneven due to moisture buildup. Properly flouring the schnitzel ensures a crisp, golden crust after frying, enhancing both texture and flavor.

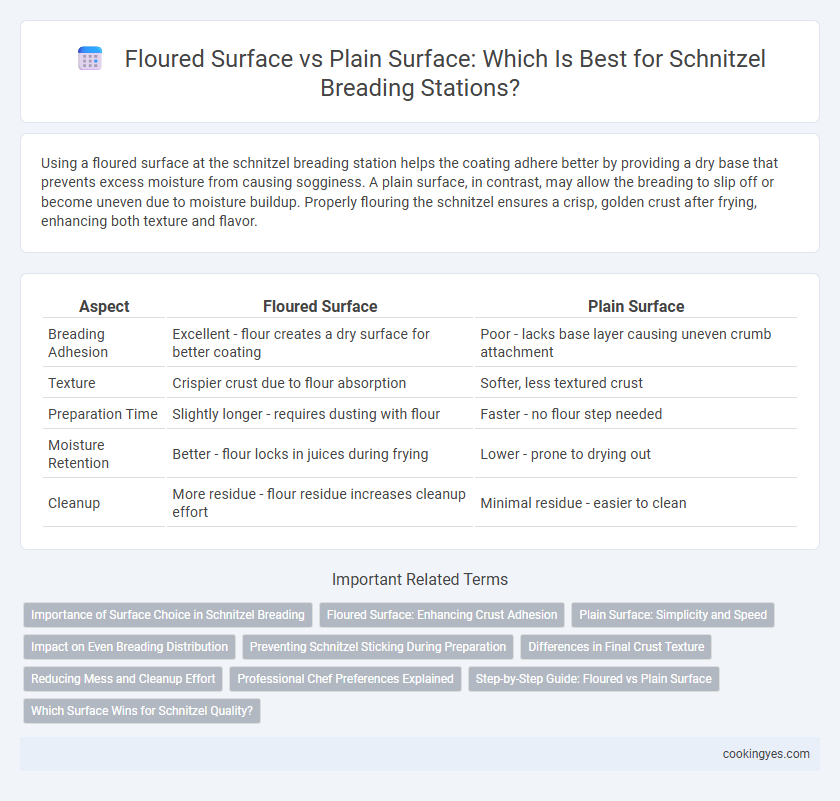

Table of Comparison

| Aspect | Floured Surface | Plain Surface |

|---|---|---|

| Breading Adhesion | Excellent - flour creates a dry surface for better coating | Poor - lacks base layer causing uneven crumb attachment |

| Texture | Crispier crust due to flour absorption | Softer, less textured crust |

| Preparation Time | Slightly longer - requires dusting with flour | Faster - no flour step needed |

| Moisture Retention | Better - flour locks in juices during frying | Lower - prone to drying out |

| Cleanup | More residue - flour residue increases cleanup effort | Minimal residue - easier to clean |

Importance of Surface Choice in Schnitzel Breading

A floured surface provides an essential dry barrier that helps the egg wash and breadcrumbs adhere more effectively to the schnitzel, preventing sogginess and ensuring a crispy crust. In contrast, a plain surface may retain moisture, leading to uneven breading and a less desirable texture. Choosing the right surface in the breading station directly influences the schnitzel's final crunch and overall flavor quality.

Floured Surface: Enhancing Crust Adhesion

A floured surface significantly improves crust adhesion in schnitzel breading by creating a dry, even layer that helps the egg wash and breadcrumbs stick more effectively. This technique prevents clumping and uneven coating, resulting in a crispier, more consistent golden crust. Using a floured surface also reduces moisture on the meat's exterior, enhancing the final texture and flavor profile of the schnitzel.

Plain Surface: Simplicity and Speed

A plain surface in a schnitzel breading station offers unmatched simplicity by eliminating the need for flour cleanup, streamlining the breading process for faster preparation. This minimalistic approach reduces cross-contamination and allows for quicker transitions between batches, enhancing kitchen efficiency. Maintaining a smooth, plain surface also simplifies hygiene protocols, crucial for high-volume schnitzel production.

Impact on Even Breading Distribution

Using a floured surface at the schnitzel breading station creates a slightly textured base that helps the egg wash adhere evenly to the meat, resulting in better breadcrumb attachment and a more uniform coating. In contrast, a plain surface can cause the egg wash to pool or run unevenly, leading to patchy breading distribution and inconsistent crispiness after frying. Proper management of the floured surface minimizes clumping and promotes a consistent, golden-brown crust essential for authentic schnitzel quality.

Preventing Schnitzel Sticking During Preparation

Using a floured surface in the schnitzel breading station creates a dry, textured layer that prevents the meat from sticking during coating, ensuring even adhesion of egg wash and breadcrumbs. In contrast, a plain surface lacks this barrier, increasing the risk of schnitzel pieces adhering to the workstation and causing uneven breading. Maintaining a well-floured station optimizes workflow efficiency and preserves the schnitzel's delicate breading integrity.

Differences in Final Crust Texture

A floured surface creates a fine, even base layer that helps the egg wash and breadcrumbs adhere better, resulting in a crispier, more textured crust on schnitzel. A plain surface lacks this initial flour coating, often producing a thinner, less crunchy crust that may be softer or slightly soggy after frying. The flour layer is critical for achieving the traditional golden, crunchy exterior characteristic of authentic schnitzel.

Reducing Mess and Cleanup Effort

Using a floured surface at the schnitzel breading station helps contain loose flour within a defined area, reducing mess and minimizing flour dispersion on countertops and floors. A plain surface often allows flour to scatter more widely, increasing cleanup time and effort. Optimizing the breading station with a floured workspace streamlines the preparation process, making cleanup faster and more efficient.

Professional Chef Preferences Explained

Professional chefs often prefer a floured surface at the schnitzel breading station to achieve a consistent coating that adheres properly to the meat, enhancing the final texture and flavor. The flour creates a dry layer that helps the egg wash stick evenly, preventing sogginess and ensuring a crisp, golden crust. Chefs emphasize precise flouring techniques over a plain surface to maintain control over the breading process and deliver a restaurant-quality schnitzel.

Step-by-Step Guide: Floured vs Plain Surface

Flouring the surface for the schnitzel breading station ensures the meat adheres evenly to the egg wash and breadcrumbs, creating a crisp and golden crust. On a plain surface, the schnitzel may slip, causing uneven breading and patchy frying results. The step-by-step process involves first patting the meat dry, coating it in flour on a floured surface, dipping in beaten eggs, and finally pressing breadcrumbs firmly for optimal texture and flavor.

Which Surface Wins for Schnitzel Quality?

A floured surface enhances schnitzel quality by creating a dry, even coating that helps the egg wash and breadcrumbs adhere more effectively, resulting in a crispier crust. In contrast, a plain surface often causes uneven breading due to moisture that prevents proper adhesion, leading to soggier results. For optimal schnitzel texture and flavor, a floured surface clearly outperforms a plain one in the breading station.

Floured surface vs Plain surface for schnitzel breading station Infographic

cookingyes.com

cookingyes.com