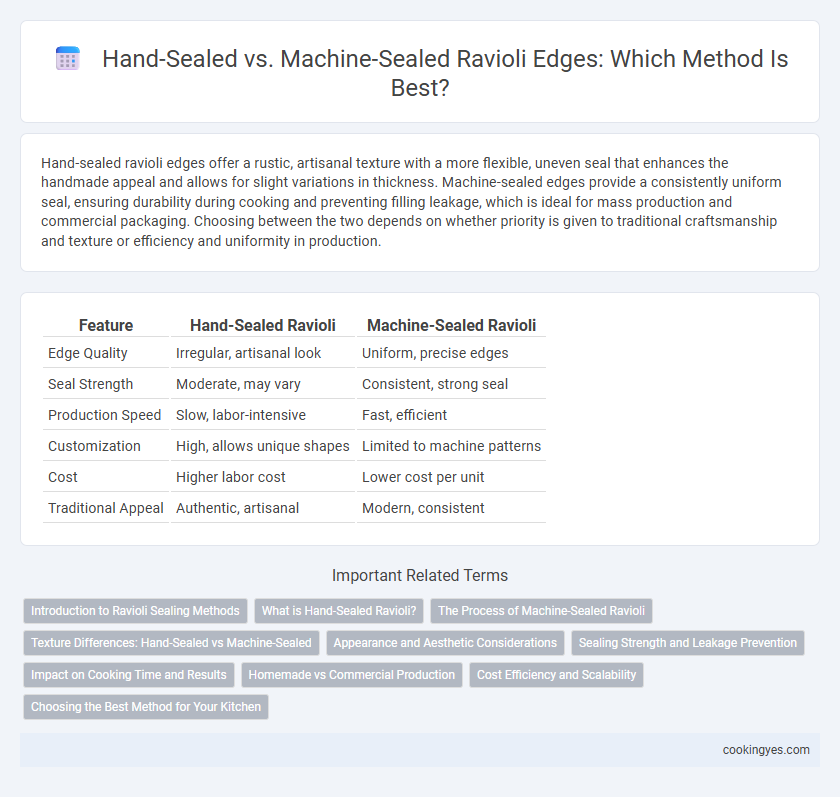

Hand-sealed ravioli edges offer a rustic, artisanal texture with a more flexible, uneven seal that enhances the handmade appeal and allows for slight variations in thickness. Machine-sealed edges provide a consistently uniform seal, ensuring durability during cooking and preventing filling leakage, which is ideal for mass production and commercial packaging. Choosing between the two depends on whether priority is given to traditional craftsmanship and texture or efficiency and uniformity in production.

Table of Comparison

| Feature | Hand-Sealed Ravioli | Machine-Sealed Ravioli |

|---|---|---|

| Edge Quality | Irregular, artisanal look | Uniform, precise edges |

| Seal Strength | Moderate, may vary | Consistent, strong seal |

| Production Speed | Slow, labor-intensive | Fast, efficient |

| Customization | High, allows unique shapes | Limited to machine patterns |

| Cost | Higher labor cost | Lower cost per unit |

| Traditional Appeal | Authentic, artisanal | Modern, consistent |

Introduction to Ravioli Sealing Methods

Hand-sealed ravioli edges offer artisanal craftsmanship, ensuring a unique texture and customizable thickness that enhances flavor retention and presentation. Machine-sealed ravioli edges provide uniformity and efficiency, reducing production time while maintaining consistent sealing strength to prevent filling leakage. Both methods impact the durability and cooking performance of ravioli, making the choice integral to product quality and consumer experience.

What is Hand-Sealed Ravioli?

Hand-sealed ravioli refers to pasta pockets whose edges are meticulously pressed and pinched by hand to ensure a tight seal, preserving the filling during cooking. This traditional method allows for greater control over the thickness and texture of the pasta edges, often resulting in a more artisanal and rustic appearance. The manual sealing process also helps prevent leaks and enhances the overall quality and taste of the ravioli compared to machine-sealed counterparts.

The Process of Machine-Sealed Ravioli

Machine-sealed ravioli edges ensure a consistent and airtight seal through precise, automated rollers that press the dough layers together, reducing the risk of leakage during cooking. This method enhances production efficiency by maintaining uniform thickness and edge shape, which is difficult to achieve manually. Automated sealing also minimizes contamination and improves shelf life by creating a tighter seal compared to hand-sealed techniques.

Texture Differences: Hand-Sealed vs Machine-Sealed

Hand-sealed ravioli edges tend to have a more varied texture, with slight imperfections that create a tender bite and enhanced pasta chewiness. Machine-sealed ravioli often feature uniform, firmer edges that provide a consistent, slightly crisp texture when cooked. The subtle differences in sealing methods affect the overall mouthfeel, with hand-sealing offering a rustic, artisanal quality and machine-sealing ensuring precision and durability.

Appearance and Aesthetic Considerations

Hand-sealed ravioli edges exhibit an artisanal, irregular appearance that emphasizes craftsmanship, appealing to consumers valuing traditional aesthetics. Machine-sealed edges provide uniformity and precision, resulting in a clean, consistent look that enhances visual appeal in mass production. The choice between hand and machine sealing directly influences the overall presentation and perceived quality of ravioli packaging.

Sealing Strength and Leakage Prevention

Hand-sealed ravioli edges offer a delicate seal that can vary in strength depending on the artisan's skill, often resulting in unique textures but a higher risk of leakage under pressure. Machine-sealed edges provide consistent sealing strength through precise, uniform pressure, greatly reducing the chance of filling leakage during cooking or freezing. Advanced sealing machinery ensures optimal edge adhesion, enhancing product durability and maintaining the ravioli's structural integrity throughout preparation and storage.

Impact on Cooking Time and Results

Hand-sealed ravioli edges typically create thicker and more uneven seals, which can extend cooking time due to less uniform heat distribution. Machine-sealed ravioli offers consistent edge thickness that allows for even cooking and prevents water from seeping inside, resulting in a tender yet firm texture. The precision of machine sealing enhances cooking efficiency and produces reliably high-quality ravioli.

Homemade vs Commercial Production

Hand-sealed ravioli edges offer unique texture and artisanal appeal, ideal for homemade preparation where precision and tradition matter. Machine-sealed edges ensure uniformity and speed, making them essential for high-volume commercial production with consistent quality standards. The choice impacts dough thickness, filling retention, and overall aesthetics in both domestic and industrial settings.

Cost Efficiency and Scalability

Hand-sealed ravioli edges typically incur higher labor costs and slower production rates, making them less cost-efficient for large-scale operations. Machine-sealed ravioli offers consistent sealing quality and significantly faster throughput, enhancing scalability while reducing per-unit labor expenses. Investing in automated sealing technology streamlines mass production, optimizing operational efficiency and cost-effectiveness in commercial ravioli manufacturing.

Choosing the Best Method for Your Kitchen

Hand-sealed ravioli edges offer artisanal precision and a traditional texture, ideal for small-scale kitchens prioritizing quality and craft. Machine-sealed edges provide consistent, airtight seals that enhance shelf-life and production speed, making them suitable for commercial operations with high volume demands. Selecting the best method depends on kitchen scale, desired product presentation, and efficiency requirements.

Hand-sealed vs Machine-sealed for ravioli edges Infographic

cookingyes.com

cookingyes.com