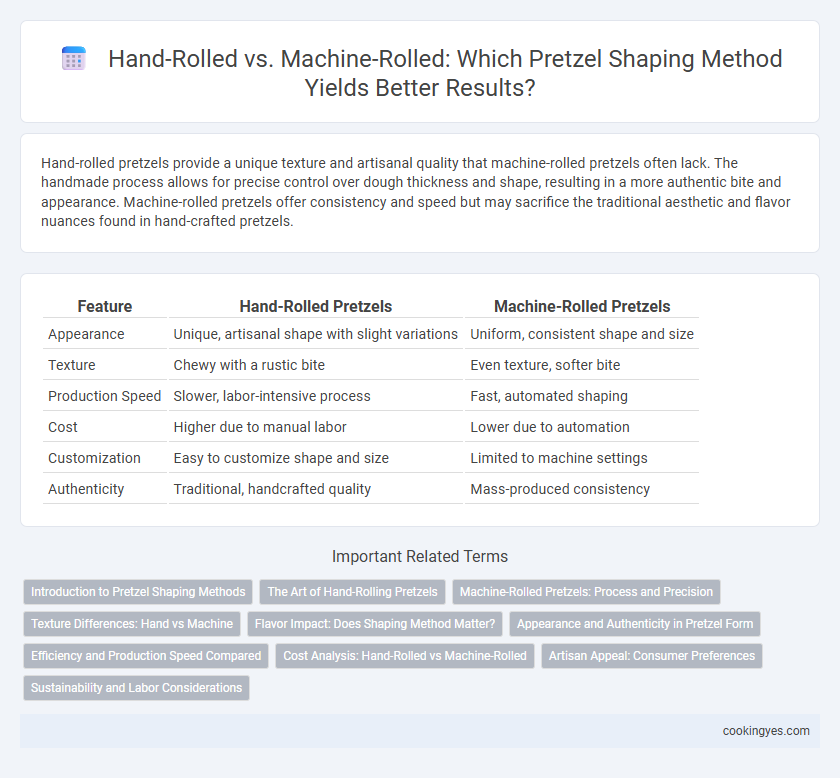

Hand-rolled pretzels provide a unique texture and artisanal quality that machine-rolled pretzels often lack. The handmade process allows for precise control over dough thickness and shape, resulting in a more authentic bite and appearance. Machine-rolled pretzels offer consistency and speed but may sacrifice the traditional aesthetic and flavor nuances found in hand-crafted pretzels.

Table of Comparison

| Feature | Hand-Rolled Pretzels | Machine-Rolled Pretzels |

|---|---|---|

| Appearance | Unique, artisanal shape with slight variations | Uniform, consistent shape and size |

| Texture | Chewy with a rustic bite | Even texture, softer bite |

| Production Speed | Slower, labor-intensive process | Fast, automated shaping |

| Cost | Higher due to manual labor | Lower due to automation |

| Customization | Easy to customize shape and size | Limited to machine settings |

| Authenticity | Traditional, handcrafted quality | Mass-produced consistency |

Introduction to Pretzel Shaping Methods

Hand-rolled pretzels exhibit unique texture and rustic character due to artisanal shaping techniques that emphasize craftsmanship. Machine-rolled pretzels ensure consistent size and uniformity, supporting large-scale production and efficient baking processes. The choice between hand-rolled and machine-rolled methods directly impacts flavor development, dough elasticity, and visual appeal, influencing consumer preference and market positioning.

The Art of Hand-Rolling Pretzels

Hand-rolled pretzels offer a unique artisanal quality that emphasizes texture and appearance, with each twist showcasing subtle variations that machines cannot replicate. This traditional technique promotes a denser crumb and chewier bite, enhancing the overall flavor profile associated with authentic German-style pretzels. Artisanal bakeries prioritize hand-rolling to maintain craftsmanship standards that elevate the sensory experience beyond mass-produced, machine-rolled alternatives.

Machine-Rolled Pretzels: Process and Precision

Machine-rolled pretzels utilize advanced automated rollers and cutters to shape dough consistently, ensuring uniform size and thickness across large batches. This process enhances production speed and precision, reducing human error and maintaining consistent texture and bake quality. Industrial-scale bakeries benefit from machine-rolled shaping by achieving efficient mass production while preserving product standards.

Texture Differences: Hand vs Machine

Hand-rolled pretzels exhibit a unique, uneven texture characterized by slight variations in thickness and a chewier bite, resulting from the artisanal pressure applied during shaping. Machine-rolled pretzels tend to have a uniform texture with consistent thickness, producing a more predictable crispness but often lacking the rustic chewiness found in hand-shaped varieties. The difference in dough handling directly influences the final mouthfeel, with hand-rolling enhancing the traditional, tactile texture prized in authentic pretzels.

Flavor Impact: Does Shaping Method Matter?

Hand-rolled pretzels exhibit a distinct texture and richer flavor profile due to uneven dough density and subtle variations in pressure during shaping, enhancing Maillard reaction development. Machine-rolled pretzels provide uniform shape and consistent density but may lack the artisanal depth that hand-rolling imparts to the crust and crumb. Flavor complexity in pretzels is directly influenced by the shaping method, making hand-rolling preferable for gourmet quality and authentic taste experiences.

Appearance and Authenticity in Pretzel Form

Hand-rolled pretzels exhibit a unique, artisanal appearance with slight variations in shape and texture, enhancing their authentic, traditional appeal. Machine-rolled pretzels, while uniform and consistent in form, often lack the rustic charm and individual character found in hand-shaped pretzels. The authenticity conveyed by hand-rolling aligns closely with consumer preferences for genuine, handcrafted baked goods, influencing perceived quality and taste.

Efficiency and Production Speed Compared

Hand-rolled pretzels offer artisanal quality with unique textures and shapes, but machine-rolled pretzels significantly enhance production speed by shaping dozens per minute with consistent thickness and form. Industrial pretzel machines streamline efficiency, reducing labor costs and minimizing human error, which is critical for large-scale manufacturing. Despite the slower pace, hand-rolling remains preferred for premium products where craftsmanship and traditional appearance impact consumer perception.

Cost Analysis: Hand-Rolled vs Machine-Rolled

Hand-rolled pretzels require skilled labor, increasing production costs due to higher wages and longer shaping times, whereas machine-rolled pretzels significantly reduce labor expenses by automating the shaping process and boosting output consistency. Initial investment in pretzel-rolling machines can be substantial, but the long-term savings on labor and increased production speed often result in a lower cost per unit. Small bakeries might prefer hand-rolling for artisanal appeal despite higher costs, while large-scale manufacturers benefit from machine-rolling efficiencies in cost and volume.

Artisan Appeal: Consumer Preferences

Hand-rolled pretzels boast a distinct artisan appeal that resonates with consumers seeking authenticity and traditional craftsmanship, often perceived as fresher and higher quality. Machine-rolled pretzels offer consistency and efficiency but lack the unique, handcrafted appearance valued by many buyers. Market trends reveal a growing preference for hand-rolled pretzels in gourmet and specialty segments, driven by the desire for artisanal food experiences.

Sustainability and Labor Considerations

Hand-rolled pretzels require skilled labor and promote artisanal craftsmanship, supporting local employment and reducing reliance on automated energy consumption. Machine-rolled pretzels offer higher production efficiency, lowering labor costs but increasing energy use and carbon footprint associated with industrial machinery. Choosing hand-rolled methods aligns with sustainable practices by minimizing environmental impact and preserving traditional food culture.

Hand-Rolled vs Machine-Rolled for Pretzel Shaping Infographic

cookingyes.com

cookingyes.com