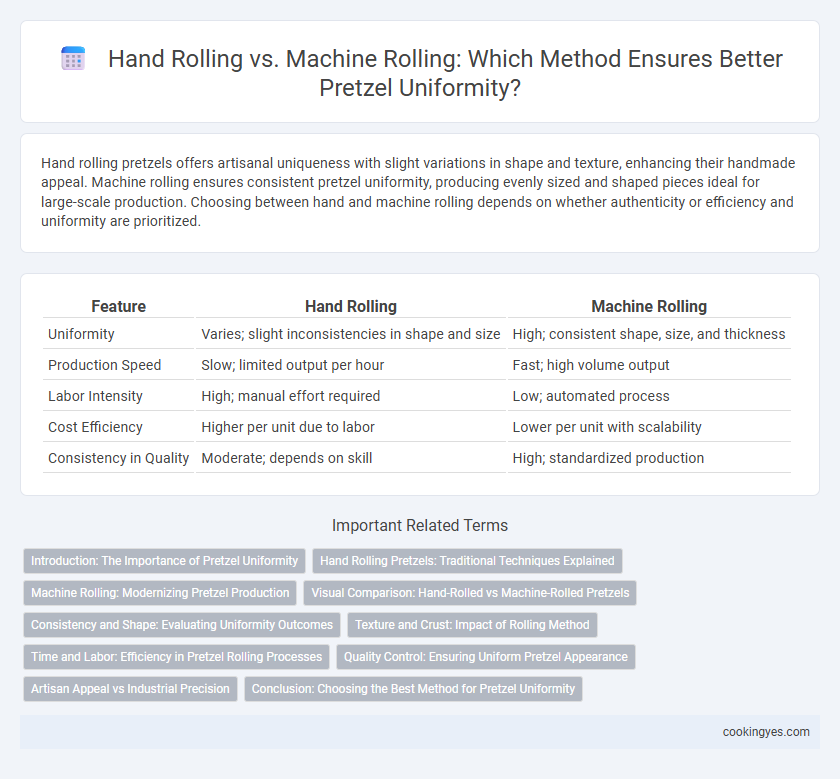

Hand rolling pretzels offers artisanal uniqueness with slight variations in shape and texture, enhancing their handmade appeal. Machine rolling ensures consistent pretzel uniformity, producing evenly sized and shaped pieces ideal for large-scale production. Choosing between hand and machine rolling depends on whether authenticity or efficiency and uniformity are prioritized.

Table of Comparison

| Feature | Hand Rolling | Machine Rolling |

|---|---|---|

| Uniformity | Varies; slight inconsistencies in shape and size | High; consistent shape, size, and thickness |

| Production Speed | Slow; limited output per hour | Fast; high volume output |

| Labor Intensity | High; manual effort required | Low; automated process |

| Cost Efficiency | Higher per unit due to labor | Lower per unit with scalability |

| Consistency in Quality | Moderate; depends on skill | High; standardized production |

Introduction: The Importance of Pretzel Uniformity

Hand rolling pretzels allows for artisanal craftsmanship and subtle variations in texture, but often results in inconsistencies in size and shape. Machine rolling ensures precise uniformity, producing pretzels with consistent thickness, weight, and appearance, which enhances baking performance and customer satisfaction. Uniform pretzels bake evenly, improving product quality and streamlining packaging and distribution processes.

Hand Rolling Pretzels: Traditional Techniques Explained

Hand rolling pretzels involves skilled artisans shaping each piece individually, ensuring unique texture and authentic character in every twist. This traditional technique allows precise control over dough thickness and knot tightness, contributing to a distinct, rustic appearance that machines often cannot replicate. The subtle variations created by hand rolling enhance the pretzel's artisanal quality and overall sensory experience.

Machine Rolling: Modernizing Pretzel Production

Machine rolling revolutionizes pretzel production by ensuring consistent shape and size, leading to uniform baking and optimal texture in every batch. Advanced mechanical rollers use precise pressure control and calibrated molds to create identical pretzels, reducing variability and increasing throughput. This technology enhances efficiency and quality control, meeting large-scale commercial demands while maintaining the traditional pretzel appeal.

Visual Comparison: Hand-Rolled vs Machine-Rolled Pretzels

Hand-rolled pretzels exhibit unique variations in shape and texture, showcasing artisanal craftsmanship with slight irregularities that appeal to consumers seeking authenticity. Machine-rolled pretzels demonstrate precise uniformity, with consistent size, shape, and surface finish that enhances production efficiency and visual predictability. This uniformity in machine-rolled pretzels supports standardized baking and packaging processes, ensuring a reliable product appearance across batches.

Consistency and Shape: Evaluating Uniformity Outcomes

Hand rolling pretzels results in subtle variations in shape and size, reflecting artisanal craftsmanship but limiting uniformity in batches. Machine rolling ensures consistent dough thickness, twist tightness, and loop size, producing pretzels with high uniformity and predictable baking outcomes. For large-scale production, machine rolling optimizes shape consistency and reduces variability, enhancing presentation and cooking performance across orders.

Texture and Crust: Impact of Rolling Method

Hand rolling pretzels creates varied texture and crust due to inconsistent pressure and shaping, resulting in a more artisanal, chewy bite with uneven browning. Machine rolling standardizes dough thickness and tension, producing uniform pretzels with consistent crust crispness and predictable texture. Uniformity in machine-rolled pretzels enhances shelf appeal, while hand-rolled variants offer unique texture profiles favored in craft baking.

Time and Labor: Efficiency in Pretzel Rolling Processes

Hand rolling pretzels requires significant time and skilled labor, leading to slower production rates and increased labor costs. Machine rolling ensures uniform pretzel shapes with faster throughput, significantly reducing manual effort while maintaining consistent dough thickness and twist tightness. This efficiency in pretzel rolling processes boosts overall productivity and cost-effectiveness in large-scale baking operations.

Quality Control: Ensuring Uniform Pretzel Appearance

Hand rolling pretzels allows for artisanal quality control, resulting in unique textures and variations that highlight craftsmanship but may sacrifice uniformity. Machine rolling ensures consistent size, shape, and weight across each pretzel, optimizing uniformity critical for packaging and branding standards. Industrial bakeries prioritize automated processes to maintain strict quality control metrics, minimizing defects and guaranteeing a consistent pretzel appearance.

Artisan Appeal vs Industrial Precision

Hand rolling pretzels offers a unique artisan appeal, showcasing craftsmanship with slight variations in shape and texture that enhance visual and tactile authenticity. Machine rolling ensures industrial precision, producing uniformly sized and shaped pretzels that meet high-volume demands with consistent quality. Balancing artisan appeal and industrial precision depends on prioritizing either aesthetic charm or operational efficiency.

Conclusion: Choosing the Best Method for Pretzel Uniformity

Hand rolling pretzels offers artisanal uniqueness with slight variations in shape and texture, appealing to small bakeries and gourmet markets. Machine rolling ensures consistent uniformity, ideal for large-scale production where standardized size, weight, and appearance are critical. Selecting the best method depends on balancing the demand for artisanal quality versus production efficiency and consistency in pretzel uniformity.

Hand rolling vs Machine rolling for pretzel uniformity Infographic

cookingyes.com

cookingyes.com