Mushroom popcorn features a round, puffy shape that offers a sturdy surface ideal for even coating applications, making it perfect for caramel and chocolate coatings. Butterfly popcorn has irregular, airy wings that provide a lighter texture but can result in uneven coating distribution. For durable, uniform glaze and toppings, mushroom popcorn is the preferred choice in snack manufacturing.

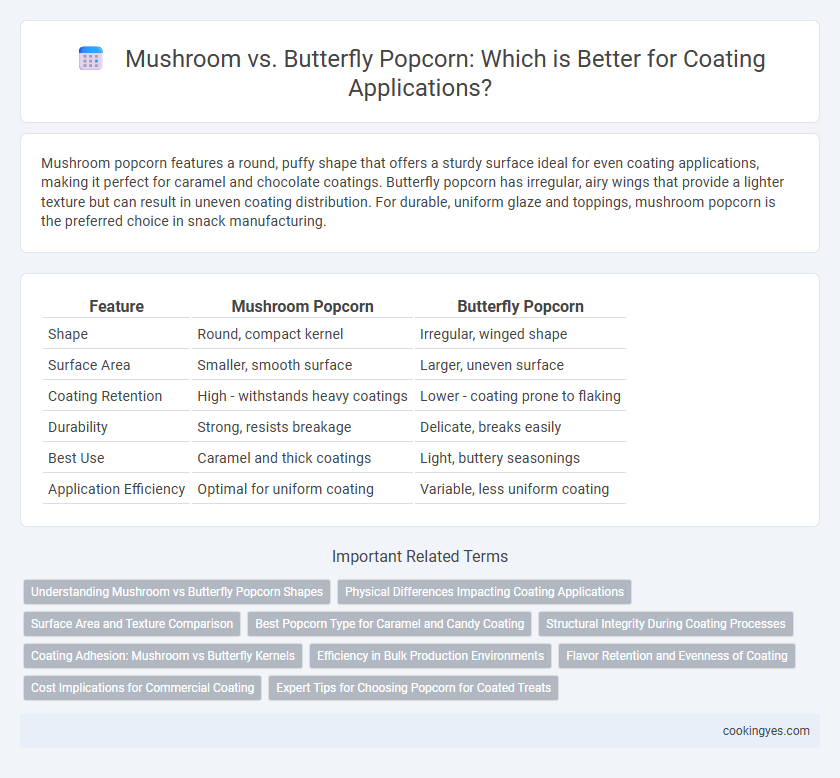

Table of Comparison

| Feature | Mushroom Popcorn | Butterfly Popcorn |

|---|---|---|

| Shape | Round, compact kernel | Irregular, winged shape |

| Surface Area | Smaller, smooth surface | Larger, uneven surface |

| Coating Retention | High - withstands heavy coatings | Lower - coating prone to flaking |

| Durability | Strong, resists breakage | Delicate, breaks easily |

| Best Use | Caramel and thick coatings | Light, buttery seasonings |

| Application Efficiency | Optimal for uniform coating | Variable, less uniform coating |

Understanding Mushroom vs Butterfly Popcorn Shapes

Mushroom popcorn features a round, compact kernel shape that provides a sturdy surface ideal for heavy coatings like caramel or cheese, ensuring even coverage and reduced breakage during processing. Butterfly popcorn has an irregular, winged shape with multiple protrusions, offering a lighter texture but less surface area for coating adherence, making it better suited for lighter, sugar-based toppings. Selecting the appropriate popcorn shape directly impacts the efficiency and quality of coating applications in snack manufacturing.

Physical Differences Impacting Coating Applications

Mushroom popcorn kernels expand into a round, compact shape with a thicker, denser surface, making them ideal for coatings like caramel or chocolate as they resist breakage and hold toppings better. Butterfly popcorn has irregular, winged shapes with thinner, more fragile surfaces that can lead to uneven coating distribution and higher kernel breakage during processing. Choosing mushroom popcorn enhances coating adherence and durability, optimizing product texture and shelf life in snack manufacturing.

Surface Area and Texture Comparison

Mushroom popcorn kernels have a rounder, more compact shape, providing a higher surface area ideal for thick coatings such as caramel or cheese due to their sturdy texture that resists breakage. Butterfly popcorn features irregular, winged shapes with larger surface area exposed and a lighter, airy texture that allows for even distribution of lighter coatings like butter or salt. The choice between mushroom and butterfly popcorn significantly impacts coating adhesion, texture retention, and overall snack quality in various commercial applications.

Best Popcorn Type for Caramel and Candy Coating

Mushroom popcorn is the best choice for caramel and candy coating applications due to its round, compact shape, which provides a sturdy surface that resists cracking and crumbling during coating. Its dense kernel structure holds up well under heavy coatings, ensuring even caramel or candy coverage without breaking. Butterfly popcorn, with its irregular shape and delicate wings, tends to absorb coatings unevenly and is more prone to breakage, making it less ideal for thick or sticky coatings.

Structural Integrity During Coating Processes

Mushroom popcorn kernels feature a round, compact shape that provides superior structural integrity during coating processes, reducing breakage and ensuring even coverage of caramel or chocolate layers. Butterfly popcorn, characterized by irregular, winged shapes, tends to be more fragile and prone to crumbling under heavy coatings, which can lead to uneven texture and product loss. The dense, robust structure of mushroom popcorn is preferred in commercial applications where durability and uniform coating retention are critical for product quality and consumer satisfaction.

Coating Adhesion: Mushroom vs Butterfly Kernels

Mushroom popcorn kernels have a round, puffy shape that provides a larger, more robust surface area for coatings to adhere to, making them ideal for applications requiring thick, crunchy coatings such as caramel or candy coatings. Butterfly popcorn, characterized by its irregular shape with protruding wings, offers less surface area and more fragile edges, leading to lower coating adhesion and increased risk of coating flaking or breakage during handling. For optimal coating adhesion and durability in snack production, mushroom popcorn is preferred over butterfly popcorn, especially for heavier or thicker coatings.

Efficiency in Bulk Production Environments

Mushroom popcorn kernels have a round, compact shape that withstands heavy coatings without breaking, making them ideal for bulk production with chocolate, caramel, or cheese coatings. Butterfly popcorn, characterized by irregular, wing-like protrusions, provides a lighter texture but often results in higher breakage and uneven coating distribution in large-scale operations. For efficiency in high-volume environments, mushroom popcorn ensures consistent coverage and reduces waste, enhancing overall production throughput.

Flavor Retention and Evenness of Coating

Mushroom popcorn's round, compact shape provides superior flavor retention and more even coating distribution, ideal for caramel, cheese, and chocolate applications. Butterfly popcorn, with its irregular shape and larger surface area, tends to absorb coatings unevenly, leading to inconsistent flavor coverage. The dense structure of mushroom popcorn prevents coating breakage during processing, ensuring a more uniform taste experience.

Cost Implications for Commercial Coating

Mushroom popcorn kernels have a round, compact shape that provides a sturdier surface ideal for thick commercial coatings, minimizing product breakage and waste, which ultimately reduces overall production costs. Butterfly popcorn, with its irregular, winged shape, tends to be more fragile during coating and packaging, leading to higher losses and increased expenses in large-scale operations. Choosing mushroom popcorn for coating applications optimizes cost efficiency by enhancing yield and lowering material loss in commercial popcorn production.

Expert Tips for Choosing Popcorn for Coated Treats

Mushroom popcorn features a round, compact kernel ideal for even, thick coatings that adhere well during candy or caramel application, minimizing breakage in coated treats. Butterfly popcorn, with its irregular shape and large, winged kernels, provides a crisp texture and is better suited for lighter coatings or seasoning due to its increased surface area. Experts recommend selecting mushroom popcorn for candy-coated snacks to ensure durability and uniform coverage, while butterfly popcorn works best for flavor-intensive, less dense coatings.

Mushroom vs butterfly popcorn for coating applications Infographic

cookingyes.com

cookingyes.com