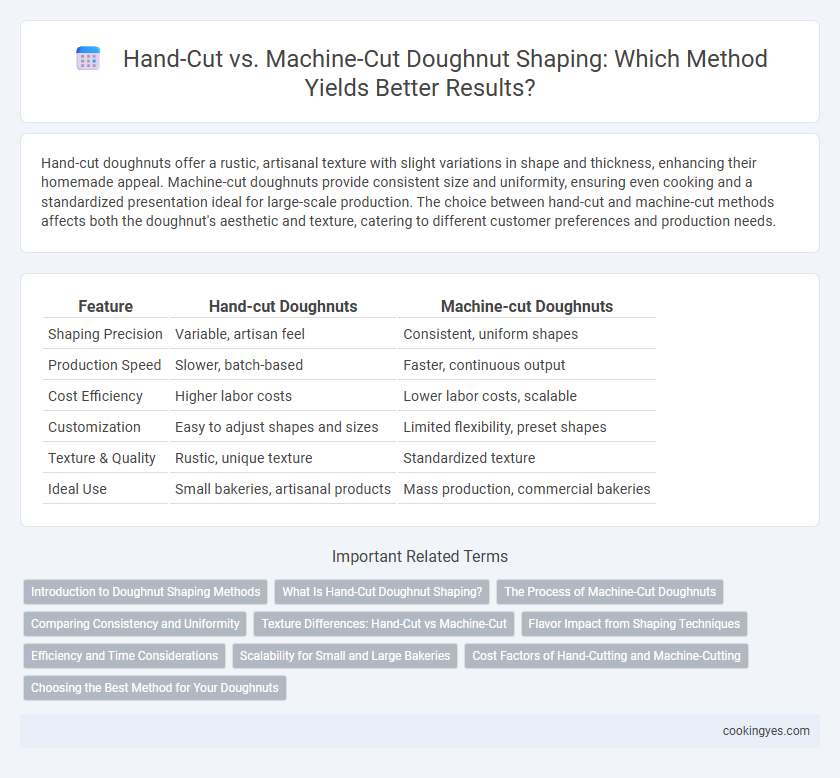

Hand-cut doughnuts offer a rustic, artisanal texture with slight variations in shape and thickness, enhancing their homemade appeal. Machine-cut doughnuts provide consistent size and uniformity, ensuring even cooking and a standardized presentation ideal for large-scale production. The choice between hand-cut and machine-cut methods affects both the doughnut's aesthetic and texture, catering to different customer preferences and production needs.

Table of Comparison

| Feature | Hand-cut Doughnuts | Machine-cut Doughnuts |

|---|---|---|

| Shaping Precision | Variable, artisan feel | Consistent, uniform shapes |

| Production Speed | Slower, batch-based | Faster, continuous output |

| Cost Efficiency | Higher labor costs | Lower labor costs, scalable |

| Customization | Easy to adjust shapes and sizes | Limited flexibility, preset shapes |

| Texture & Quality | Rustic, unique texture | Standardized texture |

| Ideal Use | Small bakeries, artisanal products | Mass production, commercial bakeries |

Introduction to Doughnut Shaping Methods

Hand-cut doughnuts offer artisanal texture and unique shapes, enhancing flavor experience through uneven edges and varying thickness. Machine-cut doughnuts guarantee uniformity and speed, providing consistent size and shape ideal for mass production and commercial use. Each shaping method influences doughnut texture, frying efficiency, and overall presentation, catering to different market needs and consumer preferences.

What Is Hand-Cut Doughnut Shaping?

Hand-cut doughnut shaping involves manually cutting dough into shapes using a doughnut cutter or a simple knife, allowing precise control over size and thickness. This traditional method ensures unique, artisanal textures and irregularities that contribute to the doughnut's handmade appeal. Hand-cut doughnuts often exhibit a distinct, rustic appearance that machine-cut doughnuts typically lack.

The Process of Machine-Cut Doughnuts

Machine-cut doughnuts are created through automated production lines that shape dough with precision and speed, ensuring consistent size and thickness. The dough passes through rollers and rotary cutters, producing uniform doughnuts that reduce manual labor and increase output efficiency. This mechanized process enhances product uniformity and streamlines large-scale doughnut manufacturing.

Comparing Consistency and Uniformity

Hand-cut doughnuts exhibit slight variations in shape and size, contributing to a more rustic and artisanal appearance but often lacking uniform consistency. Machine-cut doughnuts achieve precise, uniform shapes and sizes due to automated, repeatable cutting processes, ensuring consistent cooking times and presentation. Consistency and uniformity are superior in machine-cut doughnuts, benefiting commercial production and quality control.

Texture Differences: Hand-Cut vs Machine-Cut

Hand-cut doughnuts feature a denser, chewier texture due to the thicker, uneven dough edges, creating a more artisanal bite experience. Machine-cut doughnuts offer a consistent, even texture with a smoother crumb and uniform shape, enhancing fry time and crispness. The difference in texture largely stems from the precision of the cutting method, affecting oil absorption and final crunch.

Flavor Impact from Shaping Techniques

Hand-cut doughnuts retain uneven textures and edges that promote varied frying patterns, enhancing caramelization and creating richer, more complex flavors. Machine-cut doughnuts offer uniform shapes and consistent frying, delivering predictable texture but potentially less dynamic flavor development. The shaping technique directly influences heat distribution and dough surface area, impacting the overall taste and mouthfeel profile.

Efficiency and Time Considerations

Hand-cut doughnuts offer artisanal precision and visual appeal but require significantly more time and skilled labor, limiting overall production capacity. Machine-cut doughnuts drastically improve efficiency by producing consistent shapes at high speeds, enabling large-scale manufacturing and reducing per-unit time costs. Factories prioritize machine-cut methods to maximize throughput and meet high consumer demand without compromising uniformity.

Scalability for Small and Large Bakeries

Hand-cut doughnuts offer artisanal quality and flexibility, ideal for small bakeries aiming for unique, handcrafted products with limited daily batches. Machine-cut doughnuts enable high scalability and consistent shape, catering to large bakeries requiring mass production and uniformity across thousands of units. Choosing between hand-cut and machine-cut methods directly impacts production volume, labor costs, and product standardization in bakery operations.

Cost Factors of Hand-Cutting and Machine-Cutting

Hand-cut doughnuts typically involve higher labor costs due to the time-intensive manual shaping process, which limits production speed and increases workforce expenses. Machine-cut doughnuts reduce labor costs by automating the cutting process, enabling mass production with consistent shapes and minimizing human error. Initial investment and maintenance costs for doughnut cutting machines can be significant, but these are often offset by improved efficiency and scalability in large-scale doughnut manufacturing.

Choosing the Best Method for Your Doughnuts

Hand-cut doughnuts offer a rustic, artisanal appearance with varied shapes and thickness, ideal for small batches and creative customization. Machine-cut doughnuts provide consistent size and shape, enhancing uniform cooking and efficient production in high-volume bakeries. Selecting the best method depends on prioritizing either craftsmanship and uniqueness or speed and scalability in doughnut shaping.

Hand-cut vs Machine-cut for Doughnut Shaping Infographic

cookingyes.com

cookingyes.com