Bulk fermentation allows croissant dough to develop flavor and texture quickly at room temperature, promoting yeast activity and gluten strength. Retarded fermentation slows down yeast activity by refrigerating the dough, enhancing complex flavors and improving dough handling and layering. Choosing between bulk and retarded fermentation depends on desired flavor profile, timing, and workflow efficiency in croissant preparation.

Table of Comparison

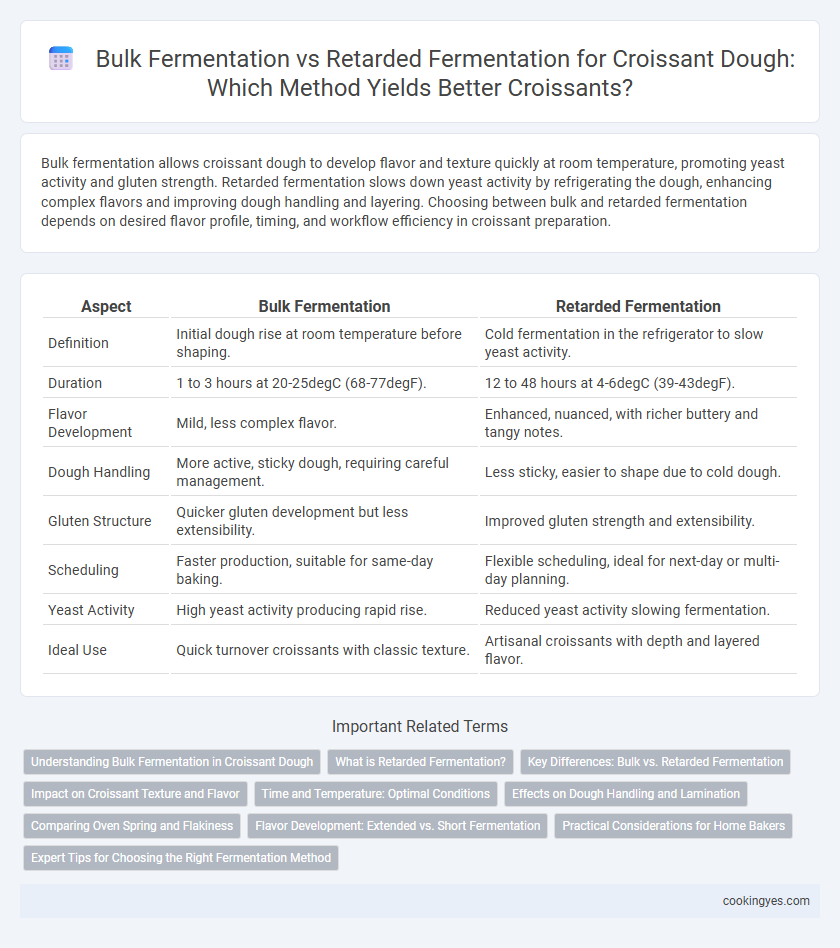

| Aspect | Bulk Fermentation | Retarded Fermentation |

|---|---|---|

| Definition | Initial dough rise at room temperature before shaping. | Cold fermentation in the refrigerator to slow yeast activity. |

| Duration | 1 to 3 hours at 20-25degC (68-77degF). | 12 to 48 hours at 4-6degC (39-43degF). |

| Flavor Development | Mild, less complex flavor. | Enhanced, nuanced, with richer buttery and tangy notes. |

| Dough Handling | More active, sticky dough, requiring careful management. | Less sticky, easier to shape due to cold dough. |

| Gluten Structure | Quicker gluten development but less extensibility. | Improved gluten strength and extensibility. |

| Scheduling | Faster production, suitable for same-day baking. | Flexible scheduling, ideal for next-day or multi-day planning. |

| Yeast Activity | High yeast activity producing rapid rise. | Reduced yeast activity slowing fermentation. |

| Ideal Use | Quick turnover croissants with classic texture. | Artisanal croissants with depth and layered flavor. |

Understanding Bulk Fermentation in Croissant Dough

Bulk fermentation in croissant dough is a crucial stage where yeast activity develops gluten structure and flavor before lamination. This process typically occurs at room temperature for several hours, allowing the dough to rise and ferment, resulting in enhanced texture and complex taste. Proper control of bulk fermentation ensures optimal yeast performance and dough elasticity, which are essential for achieving the iconic flaky layers of croissants.

What is Retarded Fermentation?

Retarded fermentation refers to the process of slowing down yeast activity in croissant dough by refrigerating it, which enhances flavor development and improves dough texture. This method allows the dough to ferment gradually over an extended period, often 12 to 24 hours, resulting in a richer, more complex taste compared to bulk fermentation at room temperature. Retarded fermentation also improves the dough's handling properties and produces a flakier, more tender croissant crumb.

Key Differences: Bulk vs. Retarded Fermentation

Bulk fermentation for croissant dough involves allowing the dough to rise at a warm temperature, typically between 75degF and 80degF, encouraging rapid yeast activity and gluten development. Retarded fermentation occurs in a refrigerated environment around 38degF, slowing yeast activity to enhance flavor complexity and develop a more pronounced buttery aroma. The key difference lies in fermentation speed and flavor development: bulk fermentation speeds up the process but produces simpler flavors, whereas retarded fermentation extends the time, resulting in croissants with superior texture and richer taste.

Impact on Croissant Texture and Flavor

Bulk fermentation allows croissant dough to develop a strong gluten network and a more pronounced yeasty flavor, resulting in a flakier and airier texture. Retarded fermentation, conducted at lower temperatures, slows yeast activity, enhancing flavor complexity through extended enzymatic reactions while promoting a tender crumb and a crisp, buttery crust. The choice between these methods significantly influences the balance of texture and flavor, with bulk fermentation favoring volume and lift, and retarded fermentation emphasizing nuanced taste and dough maturity.

Time and Temperature: Optimal Conditions

Bulk fermentation for croissant dough generally occurs at a warmer temperature of 24-27degC (75-80degF) lasting 1 to 2 hours, accelerating yeast activity and dough rise. Retarded fermentation involves refrigerating the dough at 4-7degC (39-45degF) for 12 to 24 hours, slowing yeast metabolism to develop complex flavors and improve dough texture. Optimal temperature control during fermentation profoundly influences gluten development, butter lamination, and the croissant's flaky, airy structure.

Effects on Dough Handling and Lamination

Bulk fermentation allows croissant dough to develop gluten strength and gas retention, resulting in easier handling and better lamination with distinct, flaky layers. Retarded fermentation slows yeast activity by refrigeration, enhancing flavor complexity while improving dough extensibility, reducing stickiness, and facilitating precise lamination. Optimal dough handling and lamination depend on balancing fermentation time and temperature to achieve the desired dough elasticity and layering for flaky, airy croissants.

Comparing Oven Spring and Flakiness

Bulk fermentation enhances oven spring in croissant dough by allowing yeast to develop more gas, resulting in a lighter and airier crumb. Retarded fermentation slows yeast activity by refrigeration, improving flavor complexity and gluten strength, which promotes better flakiness and distinct layered texture. Comparing both, bulk fermentation achieves vigorous rise during baking, while retarded fermentation produces superior lamination and crispness in the finished croissants.

Flavor Development: Extended vs. Short Fermentation

Bulk fermentation in croissant dough typically lasts several hours at room temperature, promoting extensive enzymatic activity that develops complex, rich flavors through greater yeast metabolism and acid production. Retarded fermentation occurs in cold storage, slowing yeast activity and extending fermentation time, which enhances subtle, nuanced flavors and improves dough handling by allowing gradual gluten development. The choice between bulk and retarded fermentation significantly influences the final croissant's aromatic profile, with bulk fermentation yielding robust, pronounced notes and retarded fermentation producing delicate, balanced flavors.

Practical Considerations for Home Bakers

Bulk fermentation for croissant dough allows home bakers to develop flavor and gluten strength quickly at room temperature, but requires careful timing to avoid overproofing. Retarded fermentation, involving slow yeast activity in the refrigerator, enhances complex flavor development and improves dough handling by extending fermentation over 12 to 24 hours. Choosing between these methods depends on baking schedule flexibility and desired taste, with retarded fermentation offering more control and better flavor for home bakers.

Expert Tips for Choosing the Right Fermentation Method

Bulk fermentation enhances flavor complexity and dough strength by allowing yeast to develop naturally at room temperature, ideal for achieving a light, airy croissant crumb. Retarded fermentation, involving cold storage, slows yeast activity to boost flavor depth and improve dough handling, making it preferred for precise scheduling and layered texture control. Expert bakers often balance bulk fermentation for optimal gluten development with retarded fermentation for enhanced aroma, tailoring methods to desired croissant characteristics and production timelines.

Bulk fermentation vs retarded fermentation for croissant dough Infographic

cookingyes.com

cookingyes.com