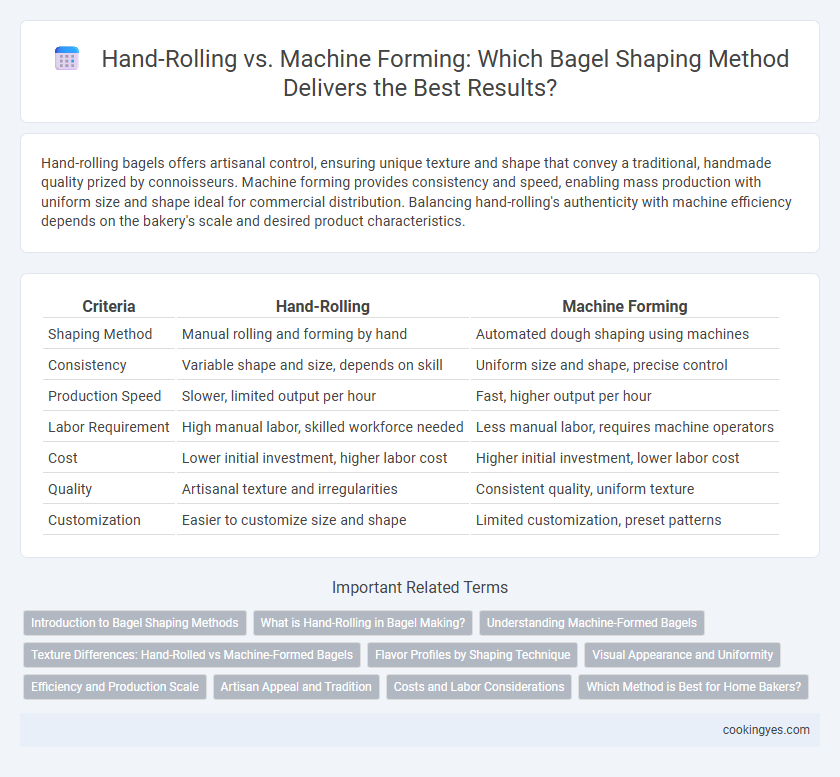

Hand-rolling bagels offers artisanal control, ensuring unique texture and shape that convey a traditional, handmade quality prized by connoisseurs. Machine forming provides consistency and speed, enabling mass production with uniform size and shape ideal for commercial distribution. Balancing hand-rolling's authenticity with machine efficiency depends on the bakery's scale and desired product characteristics.

Table of Comparison

| Criteria | Hand-Rolling | Machine Forming |

|---|---|---|

| Shaping Method | Manual rolling and forming by hand | Automated dough shaping using machines |

| Consistency | Variable shape and size, depends on skill | Uniform size and shape, precise control |

| Production Speed | Slower, limited output per hour | Fast, higher output per hour |

| Labor Requirement | High manual labor, skilled workforce needed | Less manual labor, requires machine operators |

| Cost | Lower initial investment, higher labor cost | Higher initial investment, lower labor cost |

| Quality | Artisanal texture and irregularities | Consistent quality, uniform texture |

| Customization | Easier to customize size and shape | Limited customization, preset patterns |

Introduction to Bagel Shaping Methods

Hand-rolling and machine forming are two primary methods for shaping bagels, each impacting texture and consistency. Hand-rolling allows for artisanal control, resulting in varied, rustic bagels with a dense interior and chewy crust. Machine forming ensures uniform size and shape, enhancing production efficiency for commercial bakeries while maintaining traditional bagel characteristics.

What is Hand-Rolling in Bagel Making?

Hand-rolling in bagel making is a traditional technique where bakers shape each dough piece individually by rolling it into a rope and forming a ring by joining the ends. This method allows precise control over the bagel's size and texture, resulting in a denser and chewier crust compared to machine-formed bagels. Artisan bakeries often prefer hand-rolling for its ability to produce authentic, handmade qualities that machines may not replicate.

Understanding Machine-Formed Bagels

Machine-formed bagels offer consistent size, shape, and texture by using automated equipment to quickly roll and shape dough, ensuring uniformity across large batches. This method enhances production efficiency and reduces labor costs, making it suitable for commercial bakeries aiming for high-volume output. While hand-rolling allows for artisanal texture and slight variations, machine-forming ensures repeatability and speed without compromising the essential bagel characteristics.

Texture Differences: Hand-Rolled vs Machine-Formed Bagels

Hand-rolled bagels typically exhibit a denser, chewier texture with a more artisanal crust due to the unique pressure and shaping techniques applied by the baker's hands. Machine-formed bagels often have a more uniform shape but can lack the distinct chewiness and uneven, rustic crust that hand-rolling imparts. The slight variations in hand-rolled dough promote better gluten development, enhancing the traditional bagel texture prized by enthusiasts.

Flavor Profiles by Shaping Technique

Hand-rolling bagels develops a denser crumb and chewier texture, enhancing flavor absorption during boiling and baking. Machine forming produces uniform bagels with a consistent crust but tends to yield a lighter, less complex flavor profile. The physical manipulation in hand-rolling better activates gluten, contributing to richer taste and traditional bagel characteristics.

Visual Appearance and Uniformity

Hand-rolling bagels produces unique, artisanal shapes with slight variations that enhance their homemade appeal, creating an irregular but charming texture. Machine forming ensures consistent size, smooth surfaces, and perfectly round shapes, improving uniformity for efficient baking and presentation in commercial settings. Visual appearance of machine-formed bagels typically features seamless edges and symmetrical holes, while hand-rolled bagels display more natural, rustic characteristics.

Efficiency and Production Scale

Hand-rolling bagels offers artisanal quality and precise control over dough texture, ideal for small batches and specialty bakeries focusing on authentic texture and appearance. Machine forming significantly increases efficiency, enabling large-scale production with consistent size and shape while reducing labor costs and time. Industrial bakeries leveraging automated bagel forming systems can produce thousands of bagels per hour, meeting high-volume demand without sacrificing uniformity.

Artisan Appeal and Tradition

Hand-rolling bagels preserves the artisan appeal and traditional craftsmanship, offering a unique texture and shape that machines cannot replicate. This method allows bakers to maintain control over dough consistency and form, enhancing the authenticity prized by bagel enthusiasts. Machine forming increases efficiency but often sacrifices the handmade quality that defines traditional bagels.

Costs and Labor Considerations

Hand-rolling bagels involves higher labor costs due to the intensive manual effort and skilled craftsmanship required, making it less scalable for large production. Machine forming reduces labor expenses by automating the shaping process, increasing output consistency and speed while minimizing the need for specialized workers. However, initial investment in machinery can be substantial, requiring careful cost-benefit analysis based on production volume and long-term operational savings.

Which Method is Best for Home Bakers?

Hand-rolling bagels allows home bakers greater control over dough texture and shape, producing authentic, chewy bagels with traditional irregularities. Machine forming offers consistency and speed, but may result in denser, less artisanal bagels lacking the distinctive hand-crafted look. For home bakers prioritizing quality and personal touch, hand-rolling remains the preferred shaping method.

Hand-rolling vs Machine forming for bagel shaping Infographic

cookingyes.com

cookingyes.com