Manual linking in sausage production offers precise control over sausage length and casing tension, ensuring consistent quality for artisan or small-batch products. Automatic linking systems increase efficiency and speed by mechanically segmenting sausages, reducing labor costs and boosting output in large-scale operations. Choosing between manual and automatic linking depends on production volume, desired product uniformity, and budget considerations.

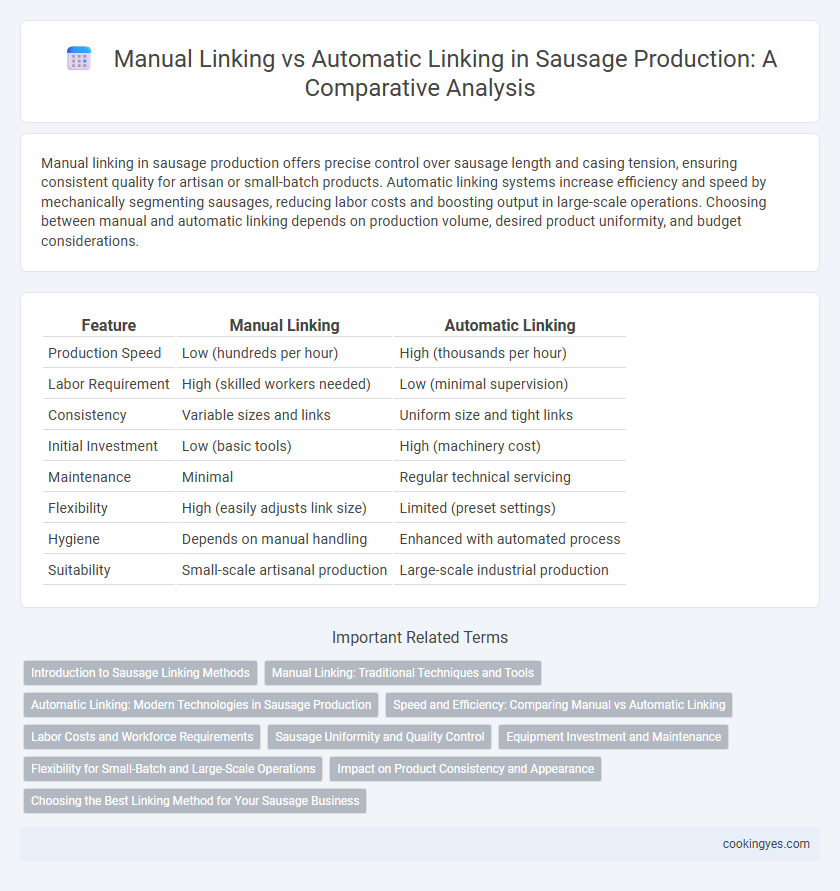

Table of Comparison

| Feature | Manual Linking | Automatic Linking |

|---|---|---|

| Production Speed | Low (hundreds per hour) | High (thousands per hour) |

| Labor Requirement | High (skilled workers needed) | Low (minimal supervision) |

| Consistency | Variable sizes and links | Uniform size and tight links |

| Initial Investment | Low (basic tools) | High (machinery cost) |

| Maintenance | Minimal | Regular technical servicing |

| Flexibility | High (easily adjusts link size) | Limited (preset settings) |

| Hygiene | Depends on manual handling | Enhanced with automated process |

| Suitability | Small-scale artisanal production | Large-scale industrial production |

Introduction to Sausage Linking Methods

Manual linking in sausage production involves skilled workers twisting the casing by hand to portion sausage links, allowing precise control over size and shape, essential for artisanal and specialty sausages. Automatic linking machines utilize mechanical systems to consistently divide and link sausages, enhancing production speed and uniformity, making them ideal for large-scale industrial operations. Choosing between manual and automatic linking depends on factors like production volume, product variety, and desired quality control in sausage manufacturing.

Manual Linking: Traditional Techniques and Tools

Manual linking in sausage production relies on traditional techniques using specialized tools such as casings, hog rings, and hand-held linkers to create uniform sausage links. This method allows artisans to control the size and texture of each link precisely, preserving the authentic craftsmanship associated with classic sausage making. Manual linking supports customization in small-batch production, ensuring consistent quality and the unique texture that automated machines often cannot replicate.

Automatic Linking: Modern Technologies in Sausage Production

Automatic linking in sausage production leverages advanced technologies such as high-speed automatic linkers and precision sensors to enhance consistency and efficiency. These modern systems reduce labor costs and minimize product variation by ensuring uniform casing stuffing and precise link spacing. Integration of programmable controls and real-time monitoring further optimizes production workflows, increasing overall output quality.

Speed and Efficiency: Comparing Manual vs Automatic Linking

Automatic linking in sausage production significantly enhances speed and efficiency by producing consistent links at a rapid pace, reducing downtime and labor costs compared to manual linking. Manual linking, while allowing for greater control and customization, is slower and more labor-intensive, leading to variability in link size and shape. Automated systems optimize production flow, minimize waste, and ensure uniformity, making them the preferred choice for large-scale sausage manufacturing.

Labor Costs and Workforce Requirements

Manual linking in sausage production demands higher labor costs due to increased time and skilled workforce requirements, as it involves hand-tying each link individually. Automatic linking machines significantly reduce labor expenses by streamlining the linking process and minimizing the need for specialized workers. Investment in automated equipment leads to long-term savings and efficiency, especially for large-scale sausage manufacturing operations.

Sausage Uniformity and Quality Control

Manual linking in sausage production allows for detailed control over sausage uniformity, enabling operators to adjust size and shape in real-time to meet quality standards. Automatic linking systems enhance consistency by maintaining precise portion control and uniform casing tension, reducing variability and improving overall product quality. Combining sensor technology with automated linking further optimizes quality control by detecting defects and ensuring each sausage meets strict uniformity criteria.

Equipment Investment and Maintenance

Manual linking in sausage production requires lower initial equipment investment with simpler machinery, reducing upfront capital costs but increasing labor intensity. Automatic linking demands significant investment in advanced machinery, such as high-speed linkers and automated casings, which enhances production efficiency and consistency while minimizing labor costs. Maintenance for manual equipment involves basic repairs and frequent adjustments, whereas automatic linking systems require specialized technical maintenance and regular calibration to ensure optimal performance and longevity.

Flexibility for Small-Batch and Large-Scale Operations

Manual linking in sausage production offers unmatched flexibility for small-batch operations by allowing precise control over link size and casing tension, ideal for artisanal or specialty sausages. Automatic linking systems excel in large-scale operations by delivering consistent link length and high output speed, minimizing labor costs while maintaining uniform quality. Combining manual and automatic linking methods can optimize production efficiency, catering to diverse batch sizes and product variations.

Impact on Product Consistency and Appearance

Manual linking in sausage production allows for greater control over link size and shape, enhancing product consistency and uniform appearance. Automatic linking systems improve efficiency and speed but may introduce slight variations in link dimensions, affecting uniformity. Consistent appearance is crucial for consumer appeal, making precision in linking methods a key factor in maintaining product quality.

Choosing the Best Linking Method for Your Sausage Business

Manual linking offers precise control over sausage size and shape, ensuring artisanal quality favored in niche markets. Automatic linking boosts production speed and consistency, reducing labor costs for large-scale sausage manufacturers. Evaluating production volume, desired product uniformity, and budget constraints is essential to choosing the ideal linking method for your sausage business.

Manual linking vs automatic linking for sausage production Infographic

cookingyes.com

cookingyes.com