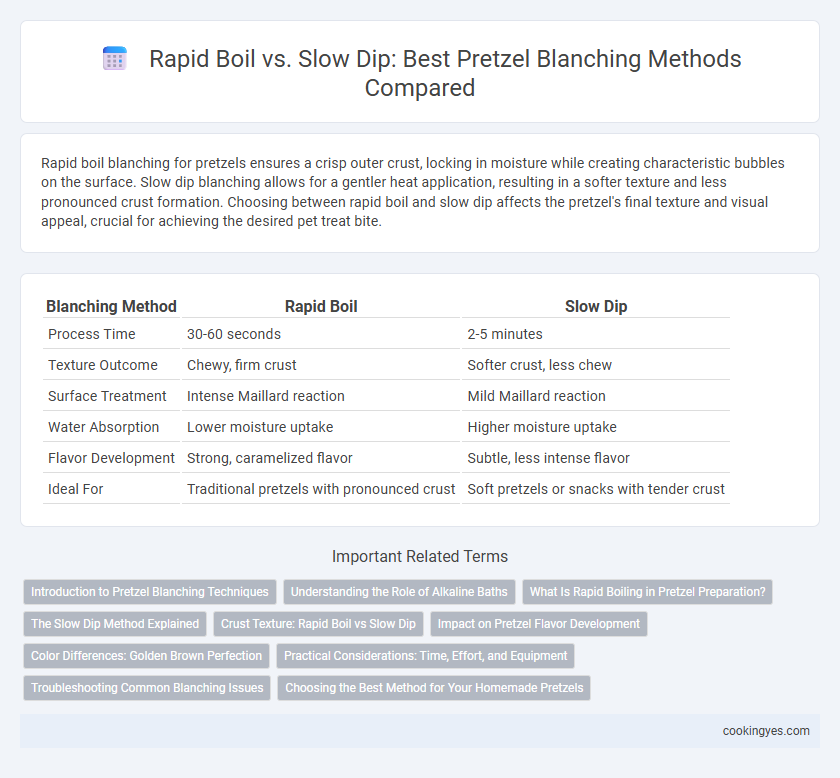

Rapid boil blanching for pretzels ensures a crisp outer crust, locking in moisture while creating characteristic bubbles on the surface. Slow dip blanching allows for a gentler heat application, resulting in a softer texture and less pronounced crust formation. Choosing between rapid boil and slow dip affects the pretzel's final texture and visual appeal, crucial for achieving the desired pet treat bite.

Table of Comparison

| Blanching Method | Rapid Boil | Slow Dip |

|---|---|---|

| Process Time | 30-60 seconds | 2-5 minutes |

| Texture Outcome | Chewy, firm crust | Softer crust, less chew |

| Surface Treatment | Intense Maillard reaction | Mild Maillard reaction |

| Water Absorption | Lower moisture uptake | Higher moisture uptake |

| Flavor Development | Strong, caramelized flavor | Subtle, less intense flavor |

| Ideal For | Traditional pretzels with pronounced crust | Soft pretzels or snacks with tender crust |

Introduction to Pretzel Blanching Techniques

Pretzel blanching involves submerging dough in hot water to influence texture and crust formation before baking. Rapid boil blanching creates a chewy crust with a more pronounced golden color by quickly gelatinizing the dough surface. Slow dip blanching results in a softer crust and lighter color, achieving a tender interior while maintaining traditional pretzel characteristics.

Understanding the Role of Alkaline Baths

Alkaline baths play a crucial role in pretzel blanching by altering the dough's surface to develop the signature crust and distinct flavor during baking. Rapid boiling in a highly alkaline solution quickly forms a dark, glossy crust and enhances Maillard reactions, while slow dipping allows for deeper alkaline penetration, which affects texture and chewiness. Understanding the balance of pH levels and immersion time in lye or baking soda baths is essential to achieve the desired pretzel characteristics.

What Is Rapid Boiling in Pretzel Preparation?

Rapid boiling in pretzel preparation refers to quickly submerging the dough in highly boiling water, typically enhanced with baking soda or lye, to gelatinize the surface starch. This process forms the characteristic chewy crust and the distinctive browned appearance after baking. Rapid boiling creates a firmer pretzel exterior compared to slow dipping, which allows more water absorption and softer crust formation.

The Slow Dip Method Explained

The slow dip method for pretzel blanching involves immersing each dough piece gradually into hot water, usually containing baking soda, to enhance the Maillard reaction and develop a chewy crust. This technique allows for more uniform water absorption and better flavor infusion compared to rapid boiling, resulting in a tender interior with a golden-brown exterior. Slow dipping also prevents dough from becoming overly dense or misshapen, ensuring the traditional soft yet slightly crispy pretzel texture.

Crust Texture: Rapid Boil vs Slow Dip

Rapid boil blanching of pretzels creates a thicker, chewier crust due to intense heat causing quick gelatinization of the dough surface. Slow dip blanching results in a thinner, softer crust with a more delicate texture as the dough absorbs water gradually without aggressive cooking. The choice between rapid boil and slow dip significantly impacts the final crust's crunchiness and moisture retention in pretzels.

Impact on Pretzel Flavor Development

Rapid boil blanching creates a more intense Maillard reaction on the pretzel surface, enhancing deep caramelized flavors and a robust crust. Slow dip blanching allows for even salt absorption and moisture retention, resulting in a softer texture with subtler flavor notes. Balancing temperature and time during blanching critically influences the pretzel's final aroma, taste complexity, and crust quality.

Color Differences: Golden Brown Perfection

Rapid boil blanching results in a pretzel with a darker, more uniform golden brown crust due to the intense Maillard reaction triggered by high heat. Slow dip blanching produces a lighter, less consistent color with softer edges, contributing to a chewier texture rather than crispness. Optimal golden brown perfection is achieved by balancing blanching time and temperature to control caramelization and crust development.

Practical Considerations: Time, Effort, and Equipment

Rapid boil blanching of pretzels significantly reduces processing time, allowing for higher throughput in commercial kitchens but requires more energy and advanced equipment to maintain consistent boil temperatures. Slow dip methods demand less specialized equipment and are easier to manage manually, but they increase labor intensity and extend preparation times, which may impact overall efficiency. Choosing between rapid boil and slow dip depends on production scale, available resources, and desired texture outcomes in the final pretzel product.

Troubleshooting Common Blanching Issues

Rapid boil blanching for pretzels often leads to uneven dough expansion and surface cracking, causing texture inconsistencies and potential breakage during baking. Slow dip blanching allows more controlled heat penetration, promoting uniform dough gelatinization and a smoother crust texture, reducing common defects like blistering or dough collapse. Troubleshooting common blanching issues involves adjusting the blanching time and temperature to balance dough elasticity and surface gelatinization for optimal pretzel quality.

Choosing the Best Method for Your Homemade Pretzels

Rapid boil blanching creates a shiny, chewy crust on homemade pretzels by quickly gelatinizing the dough's surface starches, while slow dip blanching allows for deeper salt penetration and a softer texture. Selecting the best method depends on your desired pretzel characteristics: rapid boiling suits classic, crisp pretzels, whereas slow dipping yields a tender, flavorful bite. Experimenting with water temperature and dipping duration can optimize your pretzel's taste and texture for perfect homemade results.

Rapid boil vs slow dip for pretzel blanching Infographic

cookingyes.com

cookingyes.com