Parbaking pretzels allows for longer storage by partially baking and then freezing, which helps preserve freshness without sacrificing texture. Full baking before storage can lead to a loss of moisture, resulting in a drier pretzel after reheating. Choosing parbaking for pretzel storage optimizes taste and quality when the pretzels are finished baking just before serving.

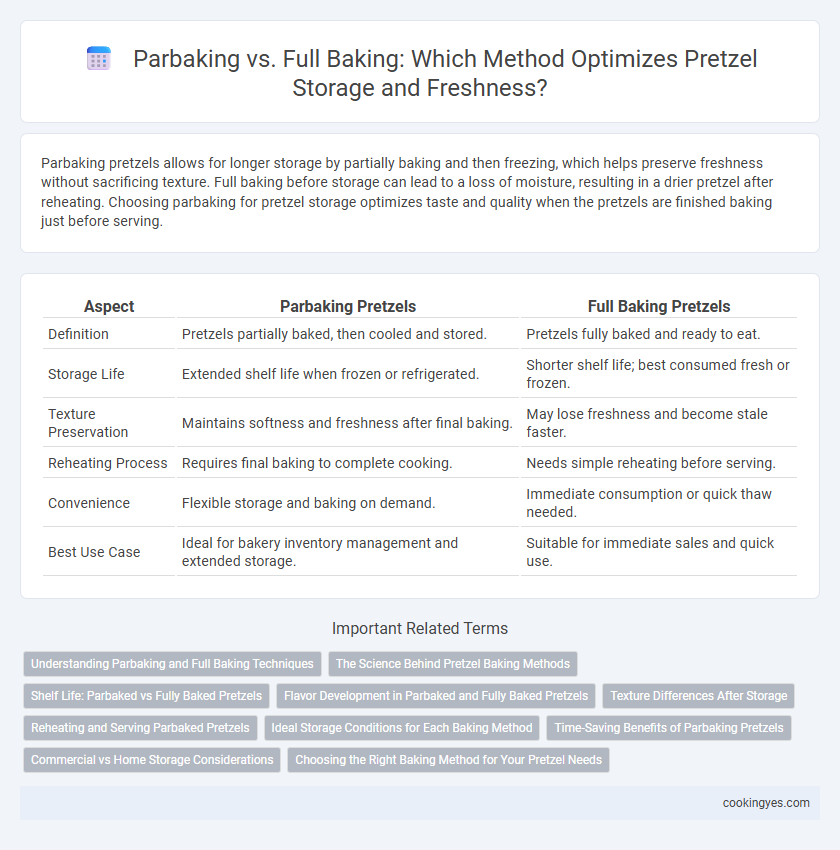

Table of Comparison

| Aspect | Parbaking Pretzels | Full Baking Pretzels |

|---|---|---|

| Definition | Pretzels partially baked, then cooled and stored. | Pretzels fully baked and ready to eat. |

| Storage Life | Extended shelf life when frozen or refrigerated. | Shorter shelf life; best consumed fresh or frozen. |

| Texture Preservation | Maintains softness and freshness after final baking. | May lose freshness and become stale faster. |

| Reheating Process | Requires final baking to complete cooking. | Needs simple reheating before serving. |

| Convenience | Flexible storage and baking on demand. | Immediate consumption or quick thaw needed. |

| Best Use Case | Ideal for bakery inventory management and extended storage. | Suitable for immediate sales and quick use. |

Understanding Parbaking and Full Baking Techniques

Parbaking involves partially baking pretzels to set their structure while halting the process before full browning, allowing for extended storage and quick finishing later. Full baking completes the entire baking cycle, producing pretzels ready to serve but with a shorter shelf life compared to parbaked ones. Understanding these techniques enables bakers to optimize freshness, texture, and convenience based on storage and serving needs.

The Science Behind Pretzel Baking Methods

Parbaking pretzels involves partially baking the dough to set the structure while retaining moisture, allowing for extended storage and fresh finishing later. Full baking fully cooks the pretzel, resulting in a crisp crust and tender interior but limits shelf life due to moisture loss over time. The science behind these methods lies in starch gelatinization and protein coagulation, where controlled heat exposure during parbaking preserves dough elasticity and yeast activity for optimal texture upon reheating.

Shelf Life: Parbaked vs Fully Baked Pretzels

Parbaked pretzels offer extended shelf life due to partial baking, which preserves moisture and slows staling compared to fully baked pretzels. Fully baked pretzels have a shorter shelf life as they are more susceptible to drying out and becoming stale quickly. Proper storage conditions such as refrigeration or freezing further enhance the longevity of parbaked pretzels, making them ideal for long-term storage.

Flavor Development in Parbaked and Fully Baked Pretzels

Parbaking pretzels enhances flavor development by partially baking the dough, allowing for extended fermentation and Maillard reactions during final baking, which intensifies the crust's caramelization and complexity. Fully baked pretzels offer immediate consumption convenience but may experience flavor diminishment over time due to staling and moisture loss. Parbaked pretzels maintain more nuanced taste profiles and fresher texture upon reheating compared to fully baked counterparts stored for prolonged periods.

Texture Differences After Storage

Parbaking pretzels locks in moisture and creates a chewier texture after storage, while full baking results in a crispier crust but can lead to dryness over time. Stored parbaked pretzels retain softness and flexibility, making them ideal for reheating without sacrificing quality. In contrast, fully baked pretzels may develop a harder crust and less tender interior after prolonged storage.

Reheating and Serving Parbaked Pretzels

Parbaked pretzels offer optimal flexibility for storage and reheating, allowing for fresh-tasting pretzels with minimal preparation time. Reheating parbaked pretzels at 350degF for 10-12 minutes restores their soft interior and crisp crust without over-baking, preserving quality better than fully baked pretzels. This method ensures consistently warm, fresh pretzels suitable for quick service or home consumption.

Ideal Storage Conditions for Each Baking Method

Parbaked pretzels require refrigeration or freezing to halt yeast activity and maintain dough texture, with recommended storage temperatures between 32degF and 40degF to preserve quality before final baking. Fully baked pretzels benefit from cool, dry storage at around 60degF to 70degF with low humidity to prevent staling and maintain crust crispness. Vacuum sealing or airtight containers enhance shelf life for both methods, reducing moisture loss and exposure to air during storage.

Time-Saving Benefits of Parbaking Pretzels

Parbaking pretzels involves partially baking them before freezing, allowing for quick final baking that preserves freshness and texture. This method significantly reduces preparation time during busy service hours, enabling bakers and retailers to offer freshly baked pretzels on demand. Parbaked pretzels maintain superior taste and quality compared to fully baked products stored long-term, making them ideal for efficient inventory management and customer satisfaction.

Commercial vs Home Storage Considerations

Parbaking pretzels extends shelf life by partially cooking and freezing them, ideal for commercial kitchens requiring rapid turnover and consistent quality across bulk batches. Full baking suits home storage, offering immediate consumption with softer texture and fresher flavor but shorter storage duration. Commercial storage prioritizes efficiency and scalability, while home storage focuses on convenience and taste freshness.

Choosing the Right Baking Method for Your Pretzel Needs

Parbaking pretzels involves partially baking them before freezing, preserving freshness and extending shelf life without compromising texture. Full baking is ideal when immediate consumption is planned, delivering a fully cooked pretzel with optimal crust and flavor. Selecting between parbaking and full baking depends on your storage duration and desired quality upon reheating or serving.

Parbaking vs Full Baking for Pretzel Storage Infographic

cookingyes.com

cookingyes.com